Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

A nickel-copper-zinc ferrite and soft magnetic technology, applied in the field of soft magnetic nickel-copper-zinc ferrite materials and their preparation, can solve problems such as large loss, and achieve the effects of low loss, simple preparation process and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

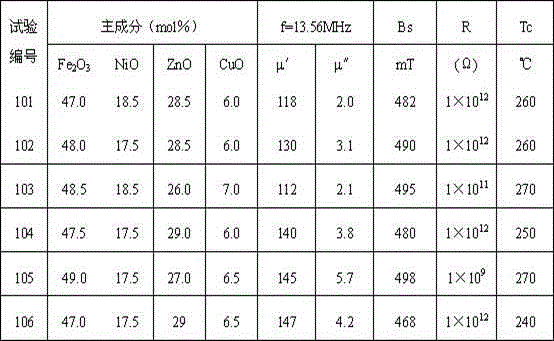

Embodiment 1

[0034] Weigh Fe with the main component content shown in Table 1 2 o 3 , NiO, ZnO and CuO raw materials, relative to the total weight of the main components, the weight percentage content of the secondary components in terms of their respective standards is: MnO: 0.30%, Bi 2 o 3 : 0.3%, Co 2 o 3 : 0.5%, Mo 2 o 3 : 0.1%, SiO 2 : 0.2%, subcomponent manganese oxide MnO and Mn 3 o 4 Add in the form of raw materials, mix and vibrate the raw materials of the main component and each auxiliary component, and then pre-fire in an air kiln at 950°C for 120 minutes to obtain pre-fired powder after preliminary reaction. Coarsely crush the calcined powder until the average particle size of the particles is 1-15μm, and then use the casting process to prepare the ferrite blank (thin-film magnetic core, a magnetic core with a length×width×height of 100mm×100mm×0.1mm) , put the blank in an air kiln at 1050° C. for sintering, and the holding time is 120 minutes to obtain the soft magnet...

Embodiment 2

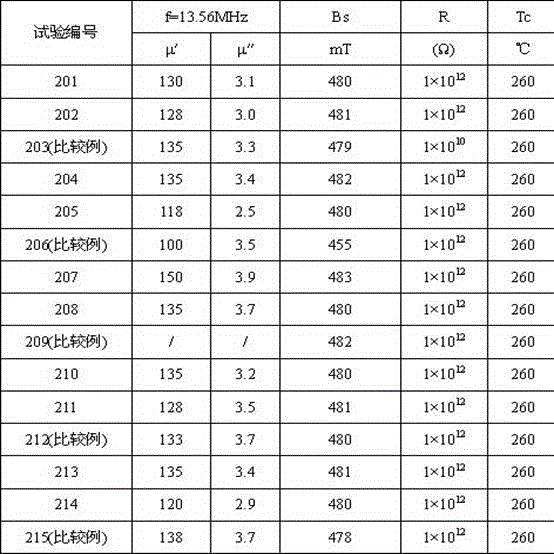

[0040] The preparation process, test instruments and test conditions of the magnetic core are the same as those in Example 1. Only Fe in the main ingredient formula 2 o 3 , NiO, ZnO, CuO content fixed at 48.0mol% Fe 2 o 3 , 17.5 mol% NiO, 28.5 mol% ZnO and 6 mol% CuO. The contents of subcomponents are shown in Table 2. The test results are shown in Table 3.

[0041] Table 2

[0042]

[0043] table 3

[0044]

[0045] Note: The test value " / " of μ' in 209 (comparative example) indicates that its value has infinitely tended to 1, so the test value of μ" has no practical significance.

[0046] As can be seen from Table 2 and Table 3, when the content of secondary components is within the scope of the present invention, the complex magnetic permeability μ " is low. The saturation magnetic flux density Bs at 25°C is above 480mT; the magnetic permeability μ at 13.56MHz ′=130±25%, μ″≤4, surface resistance R>10 9 Ω, Curie temperature Tc >250°C. When the content of the ...

Embodiment 3

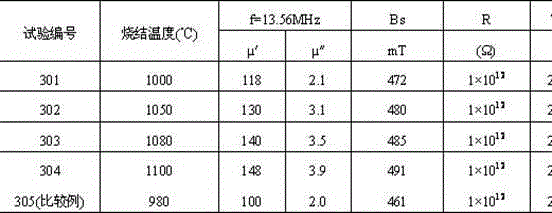

[0048] The composition of the magnetic core is the same as that of the test number 102#, and the preparation process, test instruments and test conditions are the same as those in Example 1. Only the sintering temperature is shown in Table 4.

[0049] Table 4

[0050]

[0051] It can be seen from Table 4 that when the sintering temperature is 1050-1100°C, the performance indicators of the magnetic core are better, and the temperature is lower when sintering at 980°C, resulting in magnetic permeability μ′, complex magnetic permeability μ ", saturation magnetic flux density Bs, surface resistance R, Curie temperature Tc in one or several performance indicators become worse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com