Performance test method and performance test device of high-power fracturing pump truck

A technology for fracturing pump trucks and test devices, which is applied in the direction of measuring devices, vehicle testing, power measurement, etc., can solve the problems of reducing safety risks, unable to determine the actual output power of high-power fracturing pump trucks, etc., and achieves a high safety factor , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

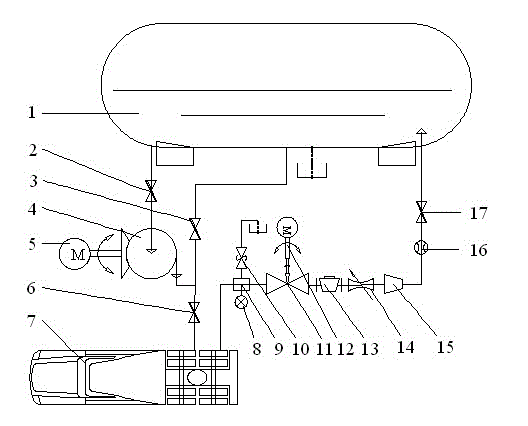

[0020] Example 1 (see figure 1 )

[0021] 1. Preparations before the test, liquid pouring cycle: connect the suction port and discharge port of the high-power fracturing pump truck 7 with the test liquid butterfly valve 6 and the high-pressure four-way port 9 respectively, and set the opening pressure of the safety valve 10 to 105 MPa , liquid supply butterfly valve 2, circulating fluid butterfly valve 3, needle valve 11, cock valve 13, throttle valve 14 and metering liquid butterfly valve 17 are in open conduction state, close test liquid butterfly valve 6, open liquid supply motor 5, and supply liquid The motor 5 drives the liquid supply centrifugal pump 4 to start pumping clean water, and the clean water flows back into the water tank 1 through the liquid supply centrifugal pump 4 along the circulating liquid butterfly valve 3 through the water tank 1, and the clean water circulation time is 5 minutes;

[0022] 2. Liquid supply test: Start the high-power fracturing pump tr...

Embodiment 2

[0029] Example 2 (see figure 1 )

[0030] 1. Preparations before the test, liquid pouring cycle: connect the suction port and discharge port of the high-power fracturing pump truck 7 with the test liquid butterfly valve 6 and the high-pressure four-way port 9 respectively, and set the opening pressure of the safety valve 10 to 105 MPa , liquid supply butterfly valve 2, circulating fluid butterfly valve 3, needle valve 11, cock valve 13, throttle valve 14 and metering liquid butterfly valve 17 are in open conduction state, close test liquid butterfly valve 6, open liquid supply motor 5, and supply liquid The motor 5 drives the liquid supply centrifugal pump 4 to start pumping clean water, and the clean water flows back into the water tank 1 through the liquid supply centrifugal pump 4 along the circulating liquid butterfly valve 3 through the water tank 1, and the clean water circulation time is 4 minutes;

[0031] 2. Liquid supply test: Start the high-power fracturing pump tr...

Embodiment 3

[0038] Embodiment 3 (see figure 1 )

[0039] 1. Preparations before the test, liquid pouring cycle: connect the suction port and discharge port of the high-power fracturing pump truck 7 with the test liquid butterfly valve 6 and the high-pressure four-way port 9 respectively, and set the opening pressure of the safety valve 10 to 70MPa , liquid supply butterfly valve 2, circulating fluid butterfly valve 3, needle valve 11, cock valve 13, throttle valve 14 and metering liquid butterfly valve 17 are in open conduction state, close test liquid butterfly valve 6, open liquid supply motor 5, and supply liquid The motor 5 drives the liquid supply centrifugal pump 4 to start pumping clean water, and the clean water flows back into the water tank 1 through the liquid supply centrifugal pump 4 along the circulating liquid butterfly valve 3 through the water tank 1, and the clean water circulation time is 3 minutes;

[0040] 2. Liquid supply test: start the high-power fracturing pump t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com