Method for preparing transmission electron microscope thin film sample of longitudinal section of filament by electrolysis double-spray method

A technology of electrolytic double spraying and transmission electron microscopy, which is applied in the preparation of test samples, etc., to achieve the effects of reducing use, reducing costs, and improving the success rate of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

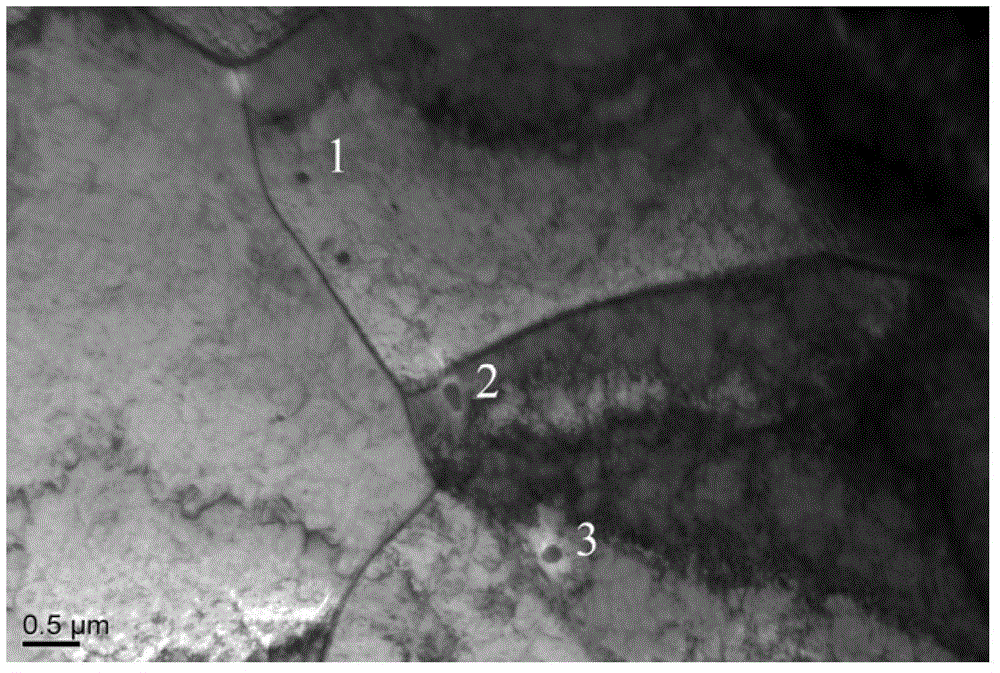

[0016] Embodiment 1: organization is the preparation of the longitudinal section thin film sample of pure ferrite

[0017] (1) Cutting the sample: the sample structure is pure ferrite, the aluminum oxide 40A15 cutting wheel is selected according to the microhardness value of the sample, the preset feed speed is 0.060 mm / s, the cutting load is adjusted to medium strength, and the cutting wheel speed is adjusted to 2500 rpm. The filaments were cut into three small sections of 2.8 mm, 2.9 mm, and 3.0 mm in length.

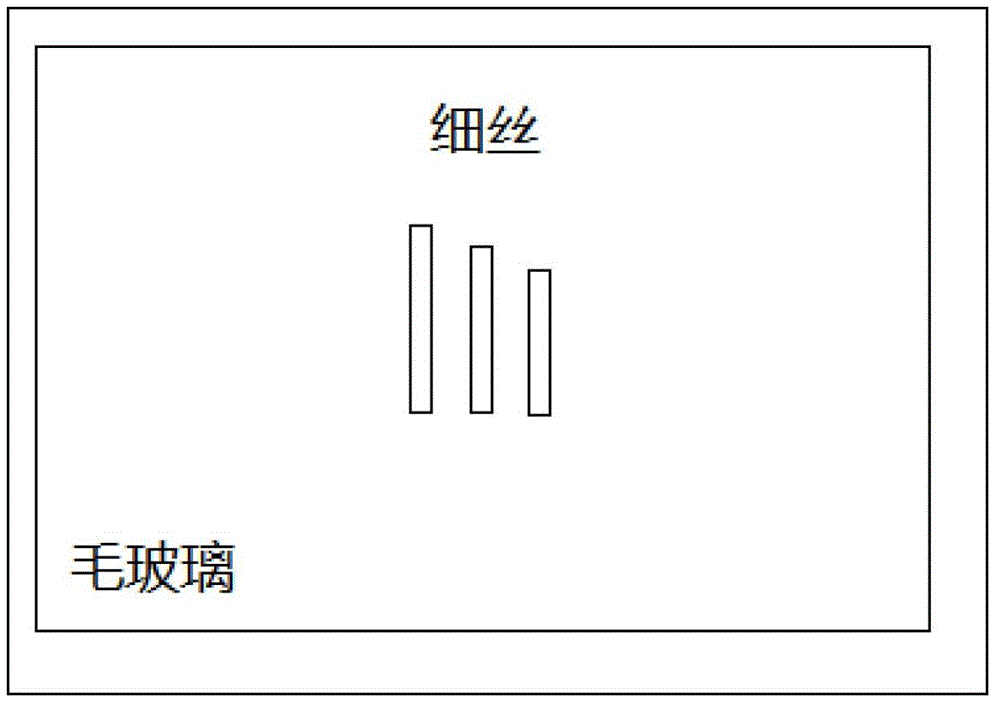

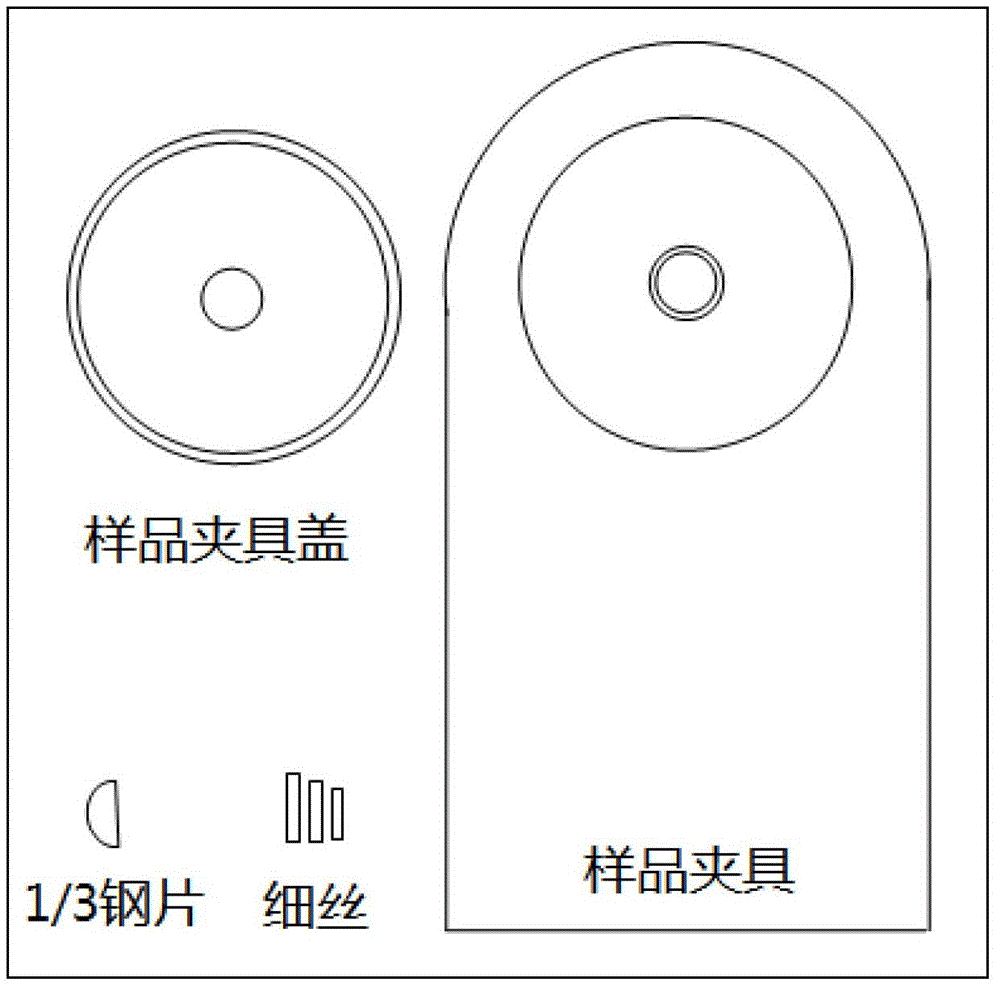

[0018] (2) Grinding samples: use flat frosted glass as the grinding and polishing plane, press a filament with a square rubber, grind a plane on 800# water sandpaper, and grind the second and third filaments in the same way. Silk. Stick the flat side of the three filaments side by side on the 10x20mm ground glass with 502 glue. After the sample is firmly pasted, use 800# water sandpaper to grind the opposite side on the flat ground glass. The two planes of the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com