Titanium alloy stress relaxation test device and method based on V-type hot bending

A stress relaxation and testing device technology, applied in the direction of applying a stable bending force to test the strength of materials, etc., can solve problems such as high equipment requirements, difficulty in reflecting the sheet forming process, and inability to directly measure stress or load data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

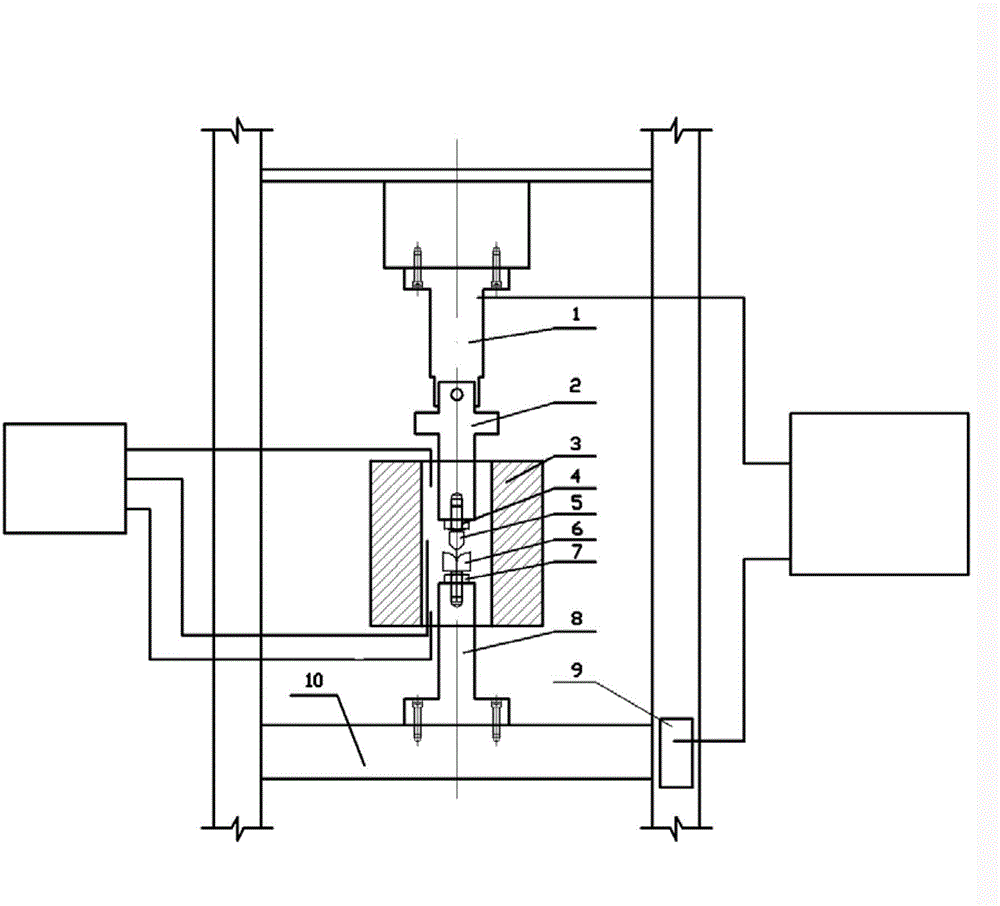

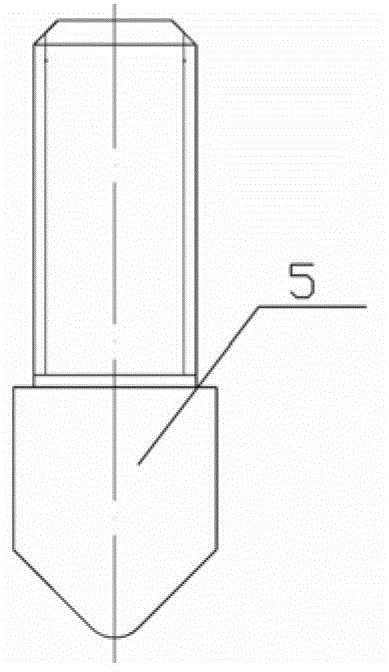

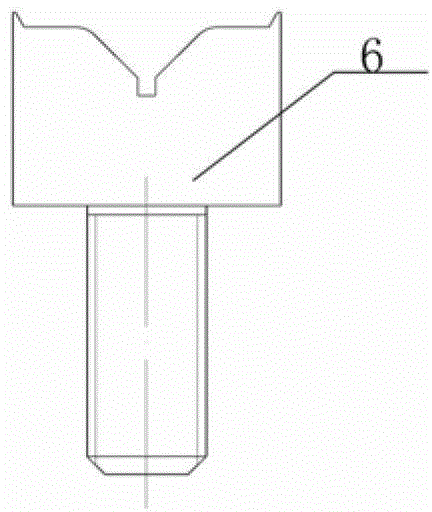

[0033] combine Figure 1-7 Describe in detail the test method for load relaxation. The materials of bending punch 5, bending die 6, upper back tightening nut 4 and lower back tightening nut 7 of the present invention are all selected 4Cr5MoSiV for use; The lower back tightening nut 7 is screwed into the bolt of the bending die 6; the bolt of the bending punch 5 is screwed into the upper pressure head 2 to a certain depth, and the bolt of the bending die 6 is screwed into the lower pressure head 8 to a certain depth. The displacement sensor 9 controls the beam 10 to move upward slowly so that the bending die 6 and the bending punch 5 are slightly aligned and in contact, and the bending punch 5 and the bending die 6 are rotated to align them in the vertical direction, and then the beam 10 is controlled again to perform bending. The die 6 is in close contact with the bending punch 5, and the upper back tightening nut 4 and the lower back tightening nut 7 are respectively tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com