Metal capacitor for all-directional connection and layout method

A metal capacitor and wiring method technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of ignoring the mutual influence of the upper and lower metal layers, reducing the efficiency of metal capacitors, sacrificing the capacitance value, etc., to reduce the layout workload and increase. Large metal capacitor, the effect of eliminating circuit noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

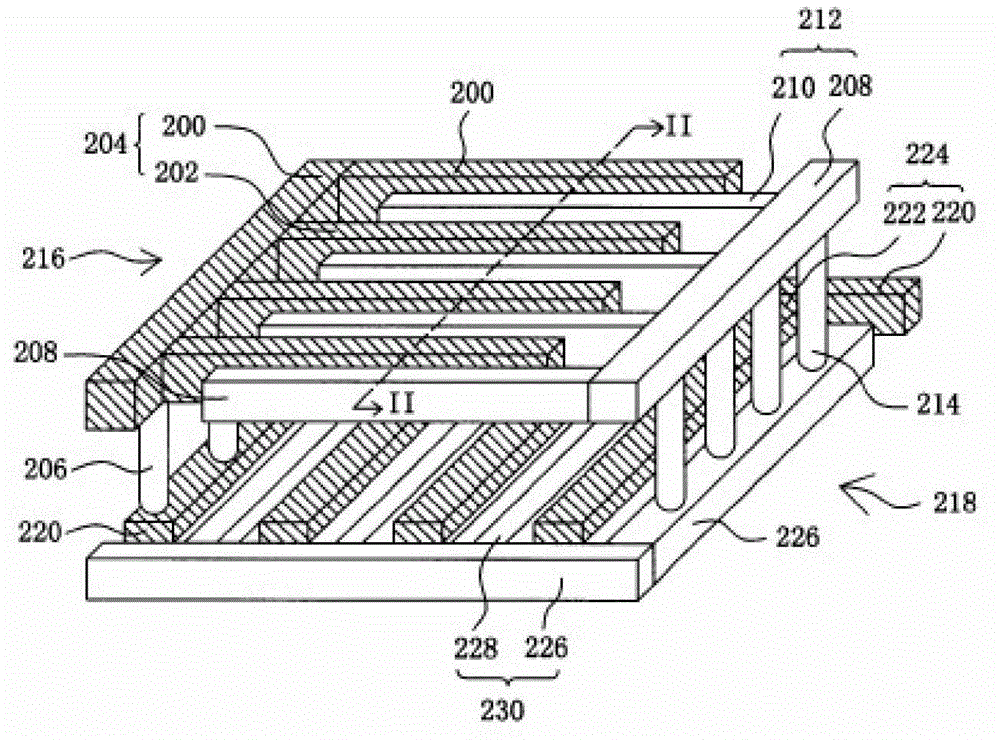

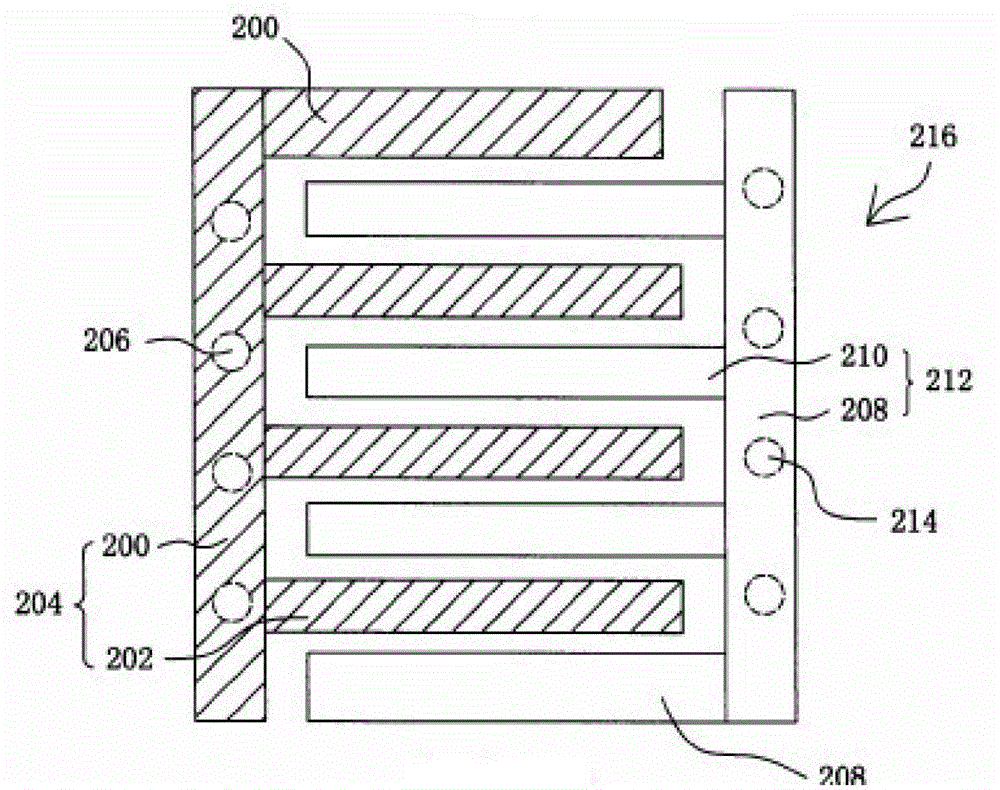

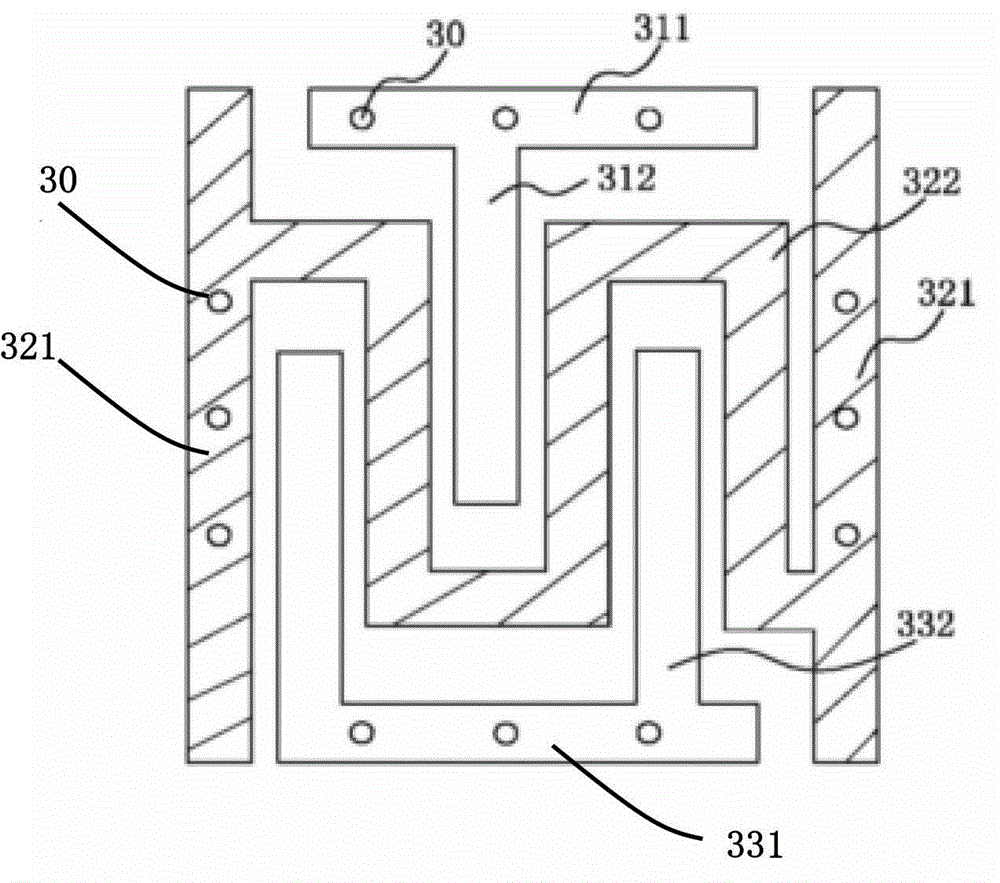

[0032] The metal capacitor with omnidirectional connection disclosed by the present invention draws on the form of the finger capacitor in the prior art to first form a unit module of a metal capacitor, including two layers of finger capacitors on an odd-numbered layer and an even-numbered layer. image 3 It is a schematic diagram of odd-numbered layer capacitance of the present invention, Figure 4 It is a schematic diagram of the even-numbered layer capacitor of the present invention, the odd-numbered layer and the even-numbered layer respectively include an upper part and a lower part, the upper part is T-shaped, and the lower part is U-shaped.

[0033] The upper and lower parts of the odd-numbered layers respectively include horizontal traces 311 and a plurality of fingers 312, and the fingers are staggered up and down, and a continuous serpentine trace 322 is also included between the fingers staggered up and down, as shown in the figure The hatched portion of the oblique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com