Backside illuminated CMOS image sensor and manufacturing method thereof

A technology of image sensor and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, radiation control devices, electrical components, etc., can solve problems such as electrical crosstalk, and achieve the effect of improving quality and electronic transition barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

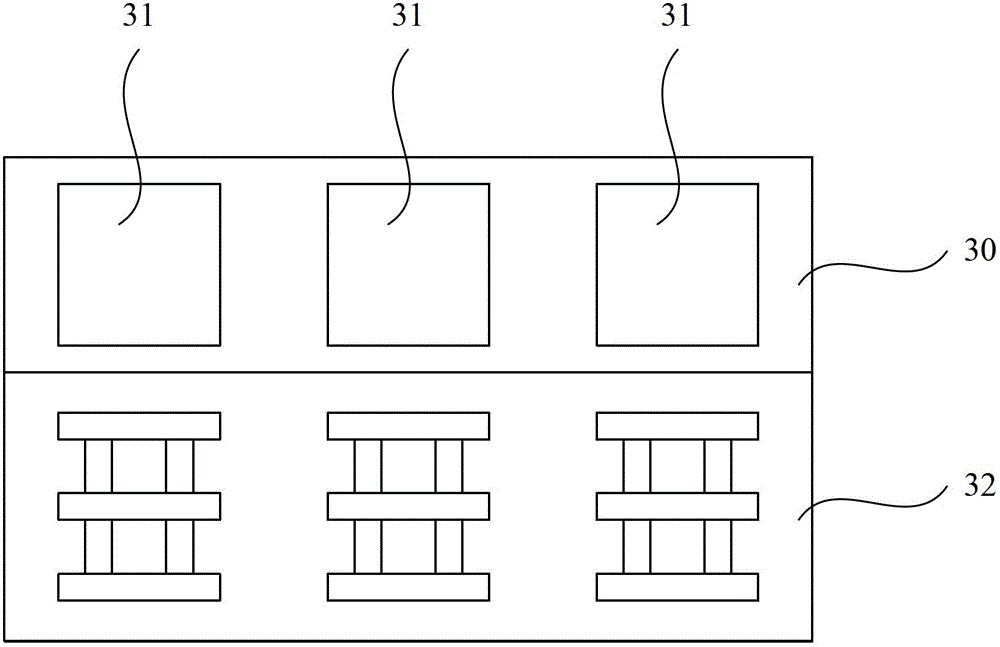

[0025] Hereinafter, the back-illuminated CMOS image sensor and the manufacturing method thereof proposed by the present invention will be further described in detail with reference to the drawings and specific embodiments. According to the following description and claims, the advantages and features of the present invention will be clearer. It should be noted that the drawings are in a very simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

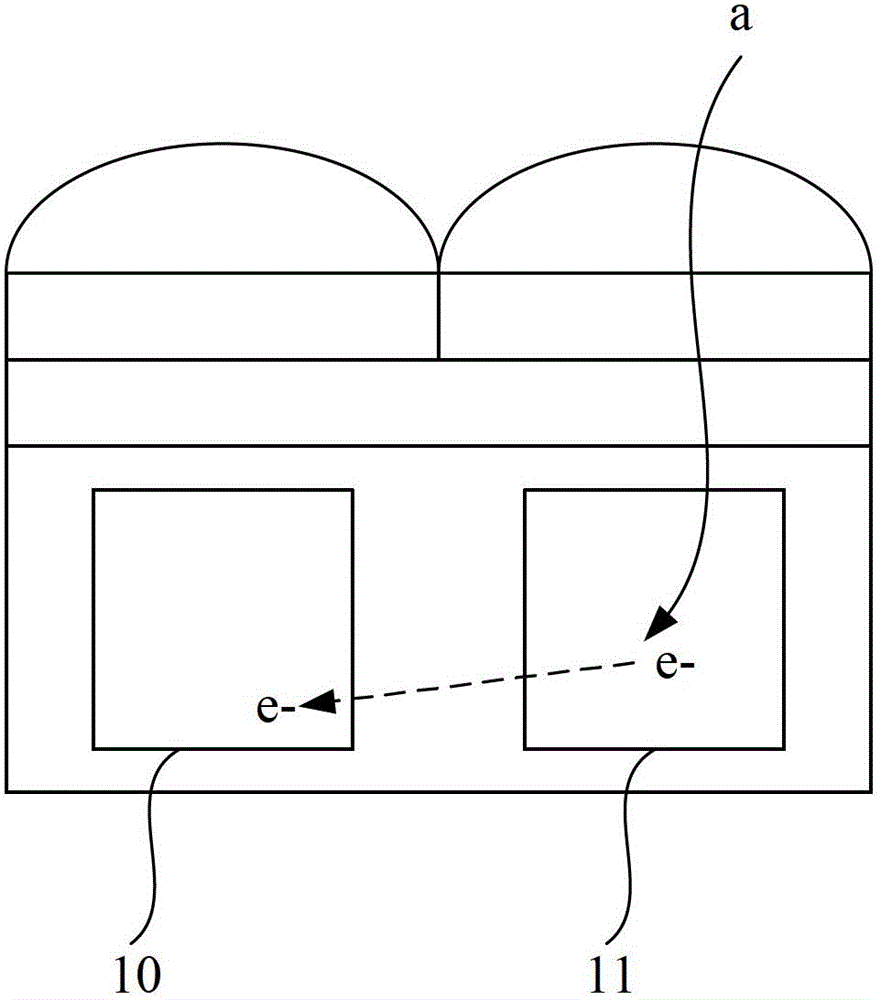

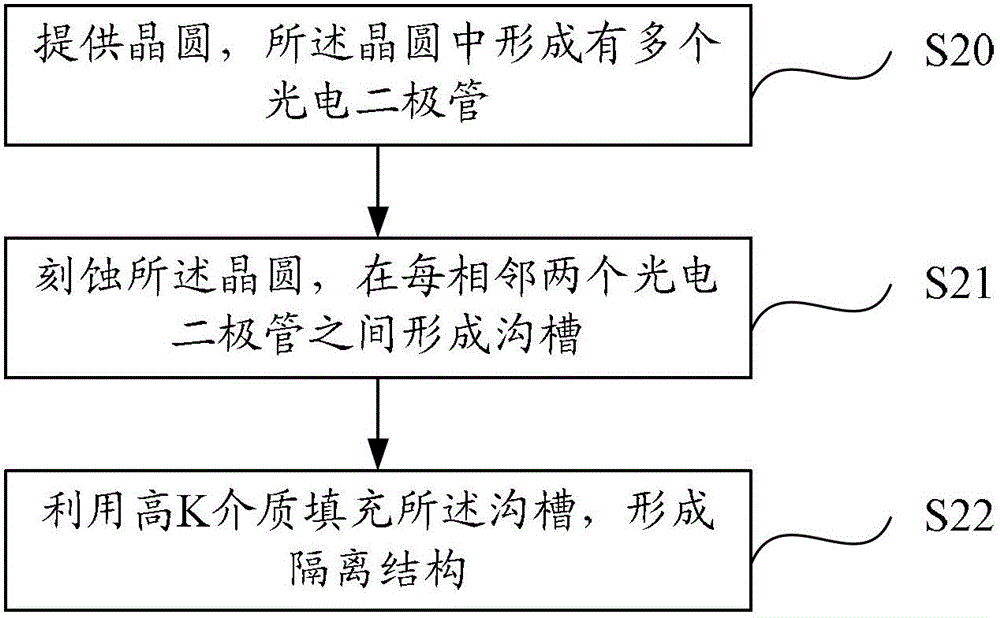

[0026] The core idea of the present invention is to block electrical crosstalk by forming an isolation structure made of a high-K medium between every two adjacent photodiodes. Since the material of the isolation structure is a high-K dielectric layer, it increases the electronic transition barrier, thereby being able to block electrical crosstalk, thereby improving the quality of the back-illuminated CMOS image se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com