Ground current isolator for radio frequency signals

A technology of radio frequency signal and ground current, applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of complex assembly process, high precision, and low production efficiency, and achieve simple assembly process, good high-frequency performance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

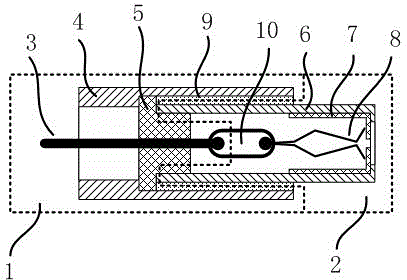

[0025] Such as figure 1 As shown, a radio frequency signal ground current isolator includes a first coaxial connector 1 and a second coaxial connector 2, the first coaxial connector 1 is formed by a first shielding layer 4 and is located on the first shielding layer 4 The second coaxial connector 2 is composed of the second shielding layer 6 and the second insulator 7 and the retaining spring 8 located in the second shielding layer 6 .

[0026] The axial section of the first insulator 5 is "T" shape, one end of the first insulator 5 abuts against the shoulder on the inner wall of the first shielding layer 4, and the outer peripheral surface of the first shielding layer 4 is smooth. The second shielding layer 6 is cylindrical, one end of the second shielding layer 6 abuts against the step of the first insulator 5, and there is a flanging inward at the other end of the second shielding layer 6, and the end of the second insulator 7 It abuts against the flange of the second shie...

Embodiment 2

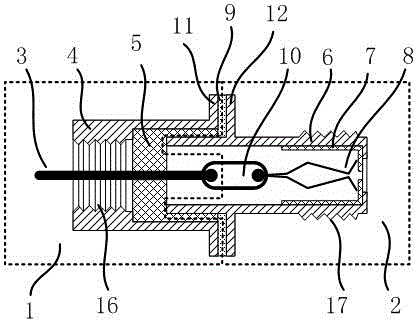

[0031] like figure 2 As shown, the difference from Embodiment 1 is that a first annular flange 11 is integrally formed at one end of the first shielding layer 4, and a second annular flange 11 is integrally formed at one end of the second shielding layer 6 close to the first coaxial connector. Ring flange 12, the first ring flange 11 and the second ring flange 12 are parallel to each other, the outer diameter of the first ring flange 11 is the same as the outer diameter of the second ring flange 12, between the end faces of the two flanges There is a gap 9 between them, the gap 9 is circular, and the outer diameter of the gap 9 is the same as that of the first ring flange 11 and the second ring flange 12 . The opening direction of the gap 9 is along the radial direction of the first shielding layer 4, and the gap 9 is filled with a dielectric material of high dielectric constant epoxy, and the dielectric material is filled from the radial direction, and the filling process is...

Embodiment 3

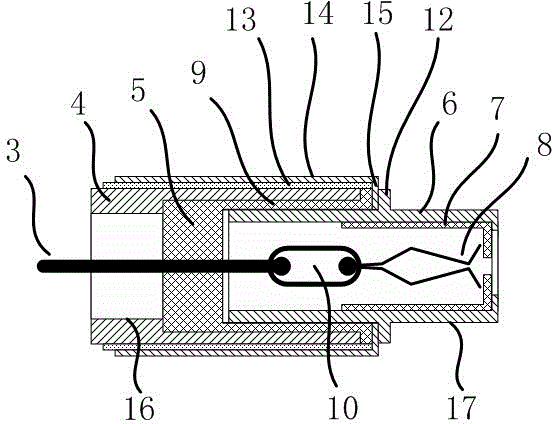

[0034] like image 3 As shown, the difference from Embodiment 1 is that the first shielding layer 4 is cylindrical and has a shoulder on its inner wall, and the second shielding layer 6 has a second annular flange 12 integrally formed in the middle. The first insulator 5 is filled in the gap 9, that is, the first insulator 5 is extended into the gap 9, the first insulator 5 has an annular outer flange, and the outer diameter of the outer flange is equal to the first shielding layer 4, That is to say, the end of the first shielding layer 4 abuts on the outer edge of the first insulator 5 , and the outer peripheral surface of the outer edge of the first insulator 5 is flush with the outer peripheral surface of the first shielding layer 4 . Then the insulating film 13 is wound on the outer peripheral surface of the first shielding layer, and the metal foil 14 is wound on the outer peripheral surface of the insulating film 13, and the insulating film 13 wraps the outer peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com