Analysis of trichloromethane stationary phase by gas chromatography method, and preparation method and applications of stationary phase

A gas chromatography and chloroform technology, applied in the field of preparation of the stationary phase, can solve the problems of high use cost of capillary column, low use temperature of packed column, etc., and achieve short analysis period, long service life and low use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

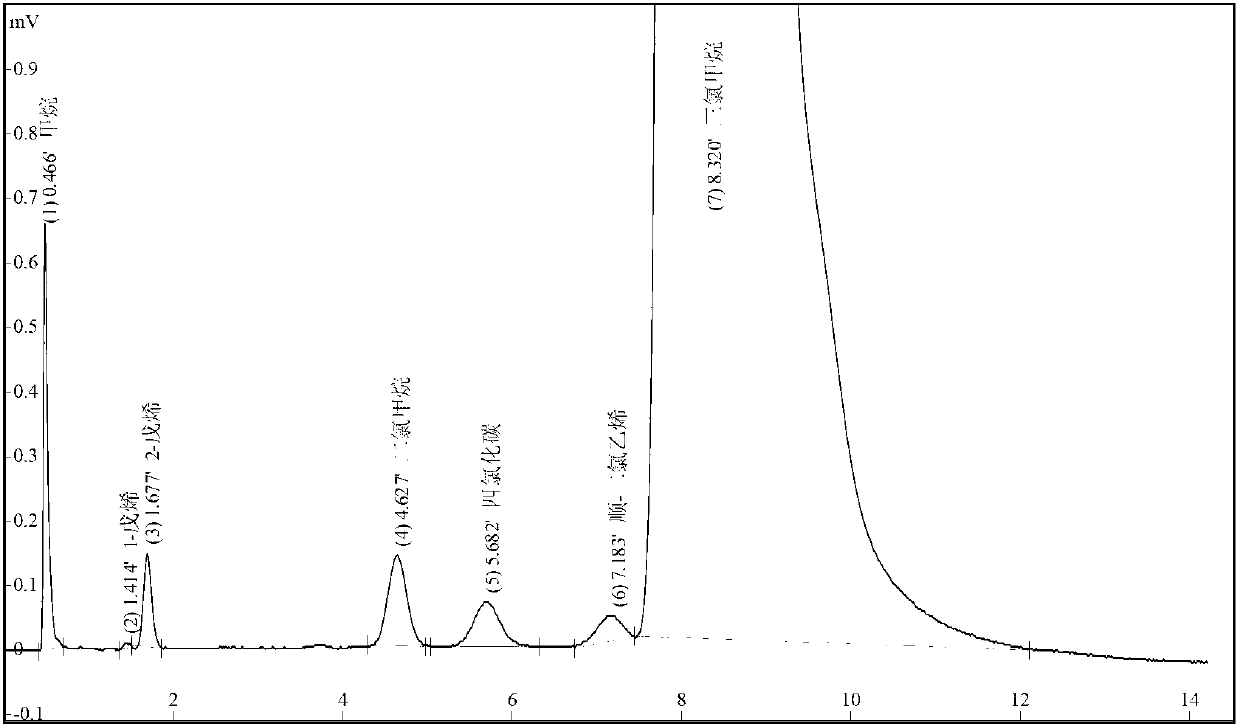

Image

Examples

Embodiment 1

[0026] The preparation of high-temperature packed chromatographic column for chloroform analysis comprises the following steps:

[0027] 1. Preparation of stationary phase

[0028] In this example, the packed column uses modified polyethylene glycol (TM-FFAP), methyl silicone rubber SE30, and 6201 support with a particle size of 60 mesh as the stationary phase at a mass ratio of 9.5:10.5:100. The specific preparation method is as follows:

[0029] A. Accurately weigh the amount of modified polyethylene glycol (TM-FFAP) and 6201 support, then add the modified polyethylene glycol (TM-FFAP) into a 250mL Erlenmeyer flask and add acetone equivalent to the volume of 6201 support , install a condenser tube and reflux at a temperature of 60°C for 1.5 hours to completely dissolve (TM-FFAP), then add the formulated amount of 6201 support to the Erlenmeyer flask, continue heating and reflux for 1.5 hours, and shake 3 times during the reflux process. Avoid sticking to the carrier on the ...

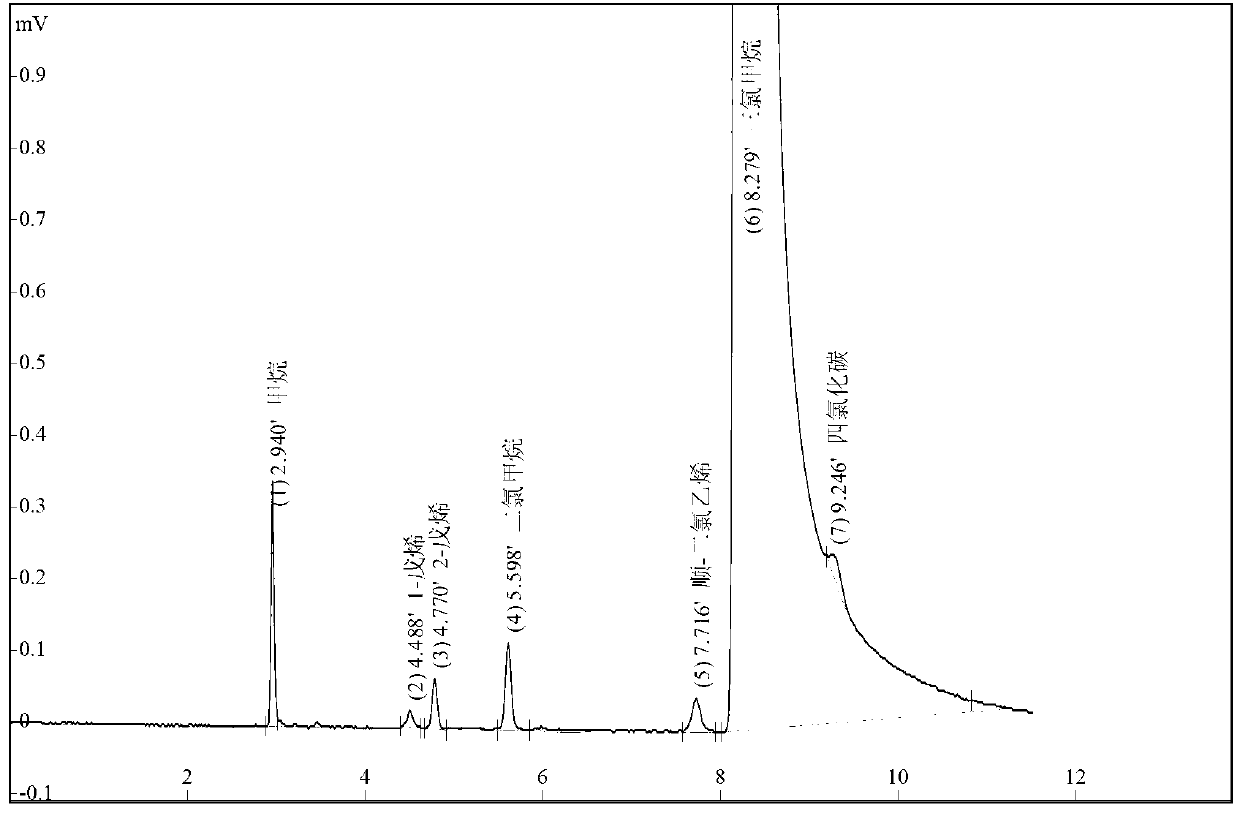

Embodiment 2

[0035] 1. Preparation of stationary phase

[0036]In this example, the packed column uses modified polyethylene glycol TM-FFAP, methyl silicone rubber SE30, and 6201 support with a particle size of 70 mesh as the stationary phase at a mass ratio of 9:11:100. The specific preparation method is as follows:

[0037] A. Accurately weigh the modified polyethylene glycol TM-FFAP and the 6201 carrier of the formula, then add the modified polyethylene glycol TM-FFAP to a 250mL Erlenmeyer flask and add acetone equivalent to 1.05 times the volume of the 6201 carrier. The upper condenser was refluxed for 1 hour at a temperature of 62 ° C to completely dissolve TM-FFAP, then add the formulated amount of 6201 support into the Erlenmeyer flask, continue heating and reflux for 3 hours, and shake 3 times during the reflux process to avoid contamination of the bottle wall. Attached carrier, after the reflux is completed, remove the condenser tube, let the acetone evaporate to dryness, and obta...

Embodiment 3

[0042] 1. Preparation of stationary phase

[0043] In this example, the packed column uses modified polyethylene glycol TM-FFAP, methyl silicone rubber SE30, and 6201 support with a particle size of 80 mesh at a mass ratio of 10:10:100 as the stationary phase. The specific preparation method is as follows:

[0044] A. Accurately weigh the modified polyethylene glycol TM-FFAP and 6201 support in the formula, then add the modified polyethylene glycol TM-FFAP into a 250mL Erlenmeyer flask and add acetone equivalent to 1.1 times the volume of the 6201 support. The upper condenser tube was refluxed for 2 hours at a temperature of 62°C to completely dissolve TM-FFAP, then add the formulated amount of 6201 support into the Erlenmeyer flask, continue heating and reflux for 2 hours, and shake twice during the reflux process to avoid contamination of the bottle wall. Attached carrier, after the reflux is completed, remove the condenser tube, let the acetone evaporate to dryness, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com