A method for removing wax deposits on oil pipelines and an associated gas recovery compressor

A technology for oil pipelines and associated gas, applied in the field of machinery, can solve the problems of reducing the service life of pipeline equipment, accelerating the corrosion of pipeline walls, and high cost of oil pipelines, and achieves the effects of preventing wax deposition, no moving parts, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

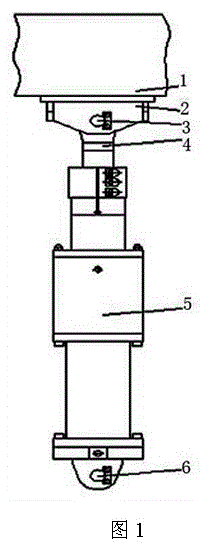

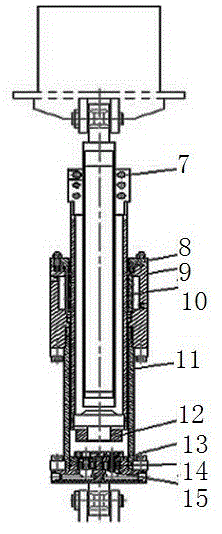

[0052] Combine below figure 1 and figure 2 Embodiments of the present invention are described, and embodiments do not constitute limitations of the present invention:

[0053]An associated gas recovery compressor, characterized in that it includes an air storage chamber, inside the air storage chamber there is a blowing piston, and two one-way valves are distributed on the air storage chamber, which are respectively air inlet one-way valves 14 and exhaust port check valve 15. Therefore, the blowing piston can realize the one-way entry and exit of gas, and then complete the pumping effect; the power of the blowing piston described here can be various, and some technical solutions that can be realized are enumerated below, and similar technical solutions are also described in this article. within the sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com