A manufacturing process of a three-way joint for optical communication

A tee joint and manufacturing process technology, applied in the field of powder metallurgy, can solve problems such as unstable machining accuracy, and achieve the effects of good consistency, simplified process, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

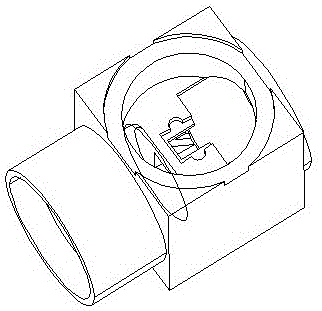

[0014] Depend on figure 1 It is known that it is the product optical communication tee joint of the present embodiment. Its production process is:

[0015] 1. Ingredients: Take: 70-85 parts of stainless steel powder; 7-8 parts of wax, 2.3-2.8 parts of polypropylene, 6.5-7.3 parts of low-pressure polyethylene, 4.5-5.2 parts of thermoplastic elastomer; first, the stainless steel powder of the above components Put the wax into the high mixer, stir at a low speed (650rpm), heat up until the temperature rises to 60-65°C, then add the above-mentioned amount of polypropylene, low-pressure polyethylene and thermoplastic elastomer to continue stirring, and control the temperature at 170-200°C. Control it for 20-30 minutes to mix the materials evenly. After discharging, cut the mixed materials into pieces, cool them, crush them, pack them into bags, and store them for later use;

[0016] 2. Injection molding: The prepared mixed material is injected by the injection molding machine thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com