Parallel indexing cam finish machining device and method

A parallel indexing and cam technology, applied in the direction of abrasive belt grinding machines, etc., can solve the problems of high tool cost and low milling surface quality, and achieve the effects of high dimensional accuracy and surface quality, low tool processing cost and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

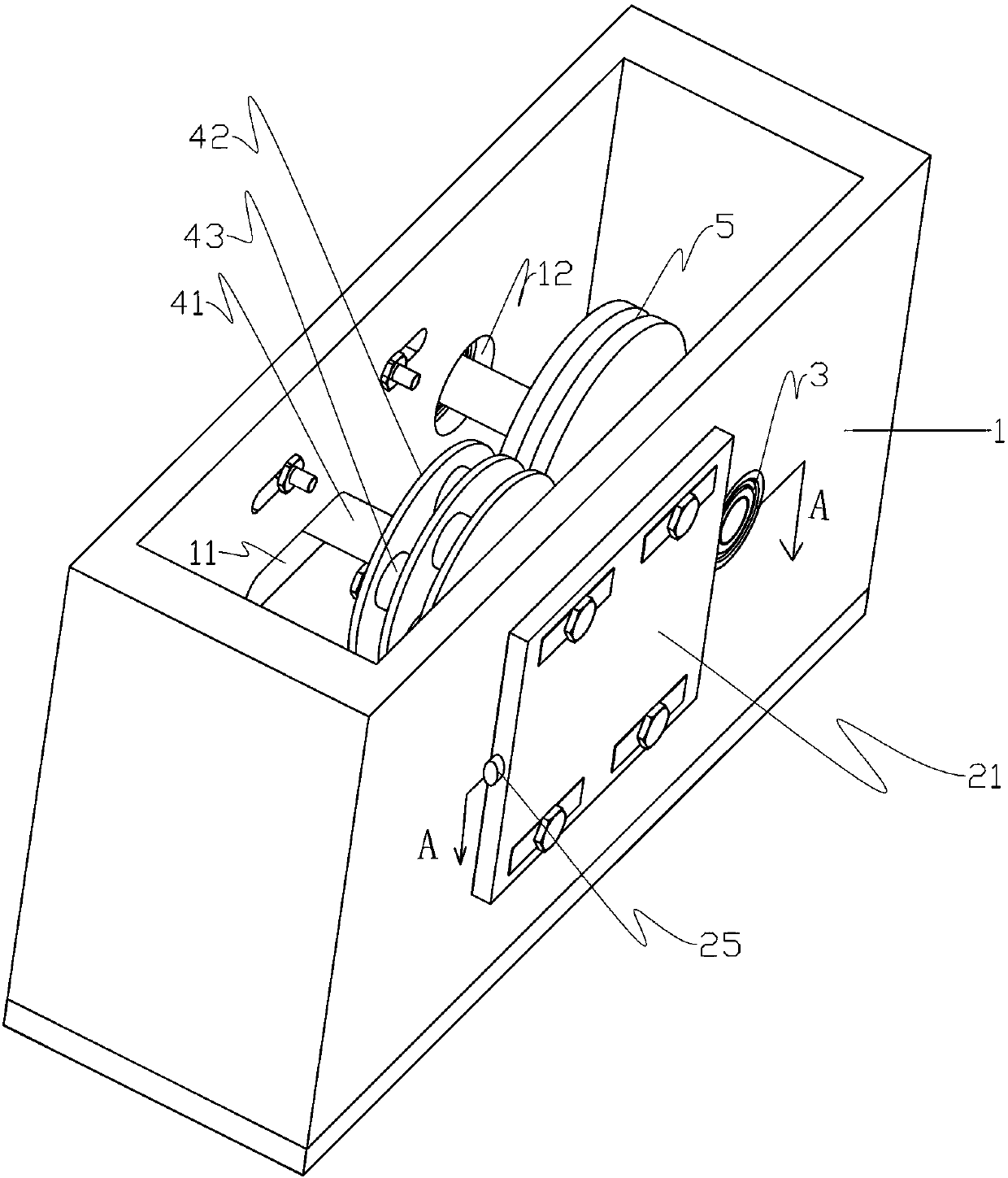

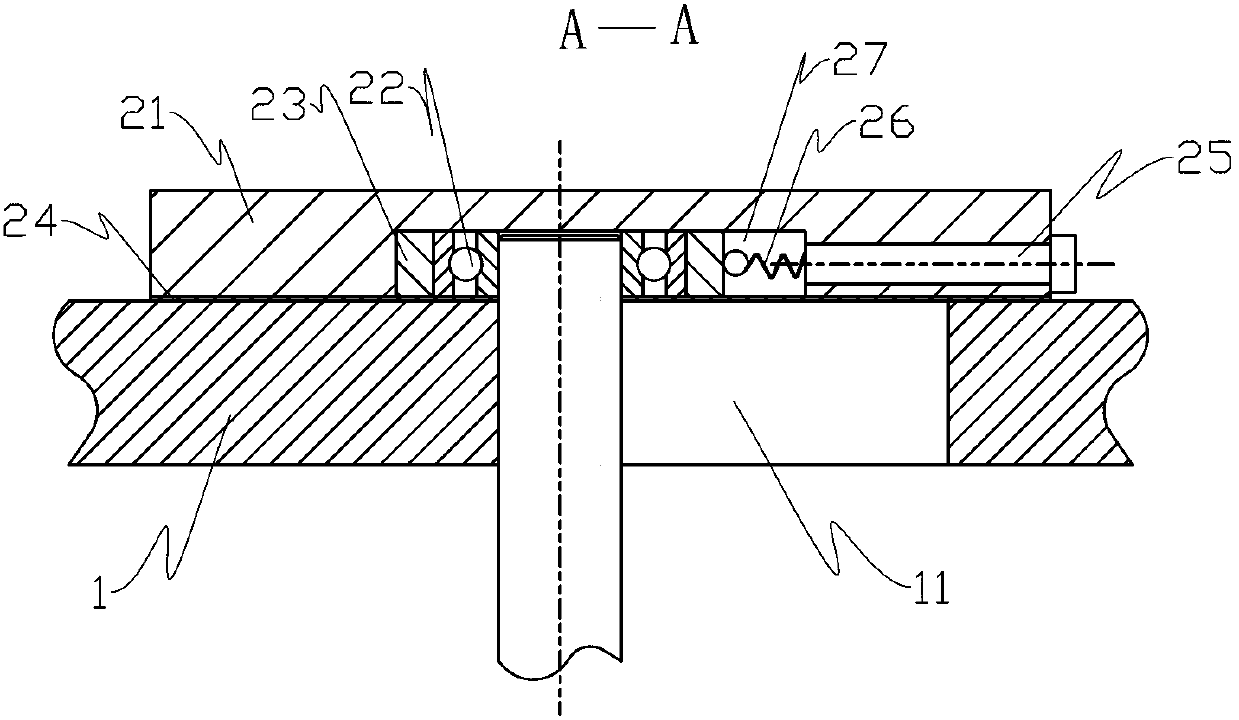

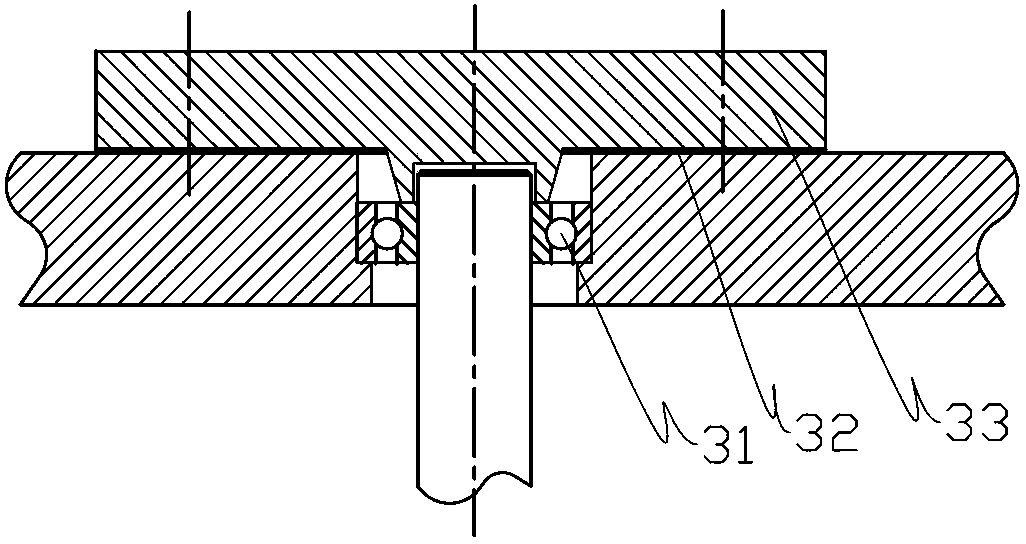

[0037] like Figure 1 to Figure 6 as shown,

[0038] The box body 1 is the installation basis of other parts, which is a rectangular slot, which can be formed by welding steel plates or stainless steel plates. The index plate fixing and adjusting assembly and the parallel indexing camshaft positioning assembly are installed on the two side walls. The degree cam and the index plate are installed inside, and the oil and abrasive mixture are contained in the inner cavity, and a box cover can be fastened on the upper part of the box to prevent the internal liquid from overflowing, and it is the supporting part of the whole device. Both the left and right side walls of the box body 1 are provided with elongated holes 11 and shaft holes 12, wherein the elongated holes are used to install the index plate, and the shaft holes are used to install parallel indexing camshafts. In the installed state, Parallel indexing camshafts and indexing plates are parallel to each other.

[0039] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com