Weighing and filling production line of particle hot and spicy sauce

A technology for chili sauce and production line is applied in the field of weighing and filling production line for granular chili sauce, which can solve the problems of inability to install a weighing device, precise control of filling time, poor control of filling amount, etc., so as to improve work efficiency and improve Efficiency, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

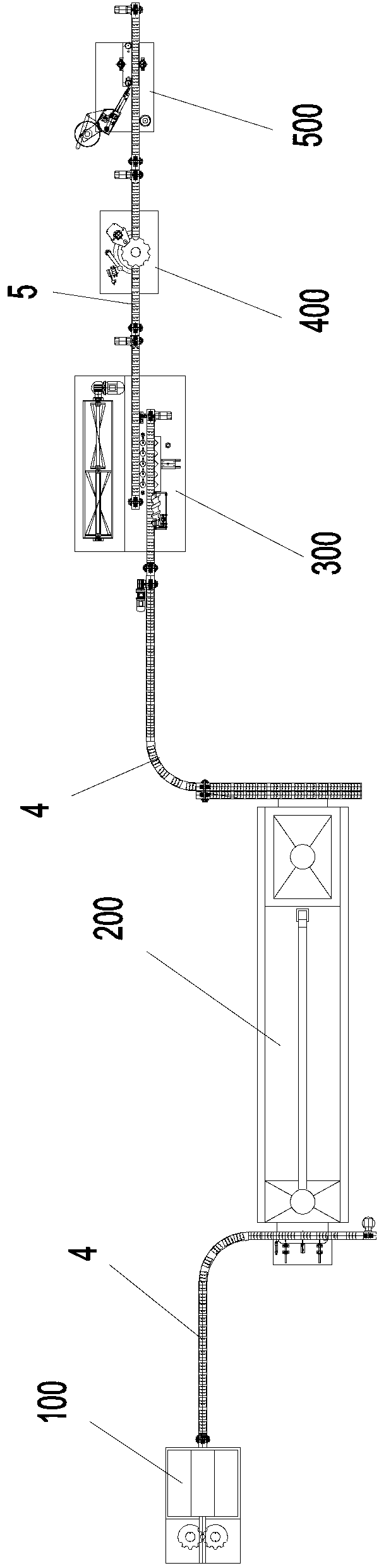

[0047] Such as figure 1 As shown, the present invention has an input conveyor belt 4 and an output conveyor belt 5; on the input conveyor belt 4, a bottle unscrambler and bottle washing machine 100, a tunnel type drying and sterilizing machine 200, and a particle filling machine 300 are sequentially arranged; on the output conveyor belt 5. The granule filling machine 300, the capping machine 400, and the labeling machine 500 are arranged in sequence;

[0048] Wherein the structures of the bottle unscrambling and bottle washing machine 100, the tunnel type drying and sterilizing machine 200, and the labeling machine 500 all adopt the prior art.

[0049] The overall production line process is: empty bottles are transported on the input conveyor belt 4, unscrambled and washed by the bottle unscrambler 100, dried and sterilized by the tunnel drying and sterilizing machine 200, and then sent to the particle filling machine 300 for further processing. It is filled into a full bottl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com