Method for preparing high-charge-density cathode electrophoretic paint

A cathodic electrophoretic coating and charge density technology, which is applied in electrophoretic coatings, epoxy resin coatings, coatings, etc., can solve the problems of affecting the anti-corrosion performance of workpieces and uneven coating thickness, so as to increase the average charge density and excellent anti-corrosion performance , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

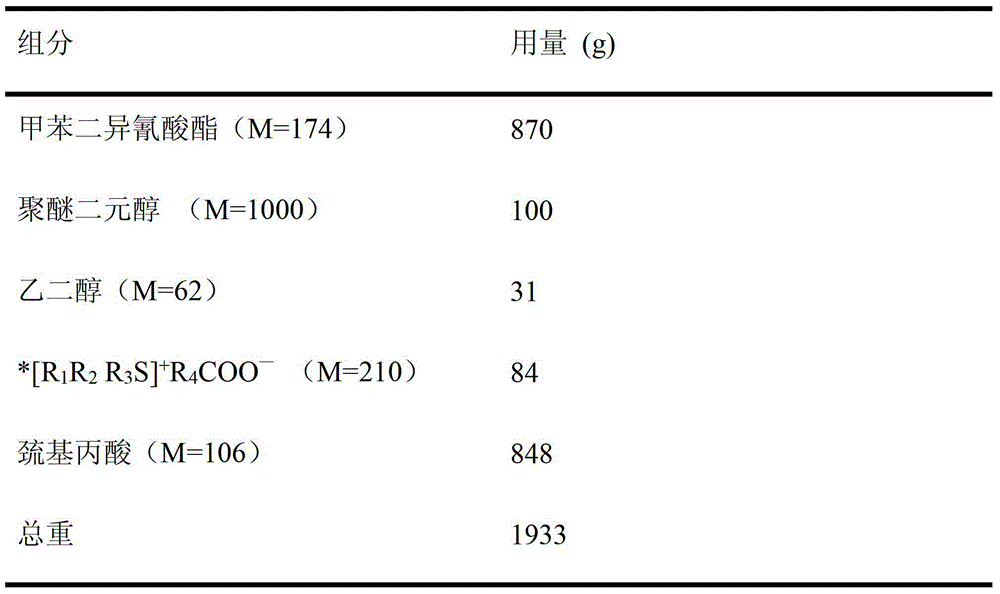

[0027] 1. Preparation of carboxyl-terminated cationic polyurethane resin

[0028]

[0029] *R 1 and R 4 is methyl, R 2 is hydroxyethyl, R 3 2-hydroxypropyl

[0030] **NCO / OH=5:1, hydrophilic group content: 4.34%

[0031] In the reaction flask equipped with a thermometer, agitator and reflux condenser, add the formulated amount of toluene diisocyanate and polyether diol in sequence, and react for 30 minutes after raising the temperature to 70°C; then add ethylene glycol, and continue the reaction at the same temperature 30min; then add hydrophilic chain extender, continue to react at the same temperature for 40min, then analyze the isocyanate group content in the prepolymer by standard di-n-butylamine back titration method, when the isocyanate group content reaches the theoretical value of 17.38% , adding mercaptopropionic acid for capping to obtain a carboxyl-terminated cationic polyurethane resin with an acid value of 232 mgKOH / g.

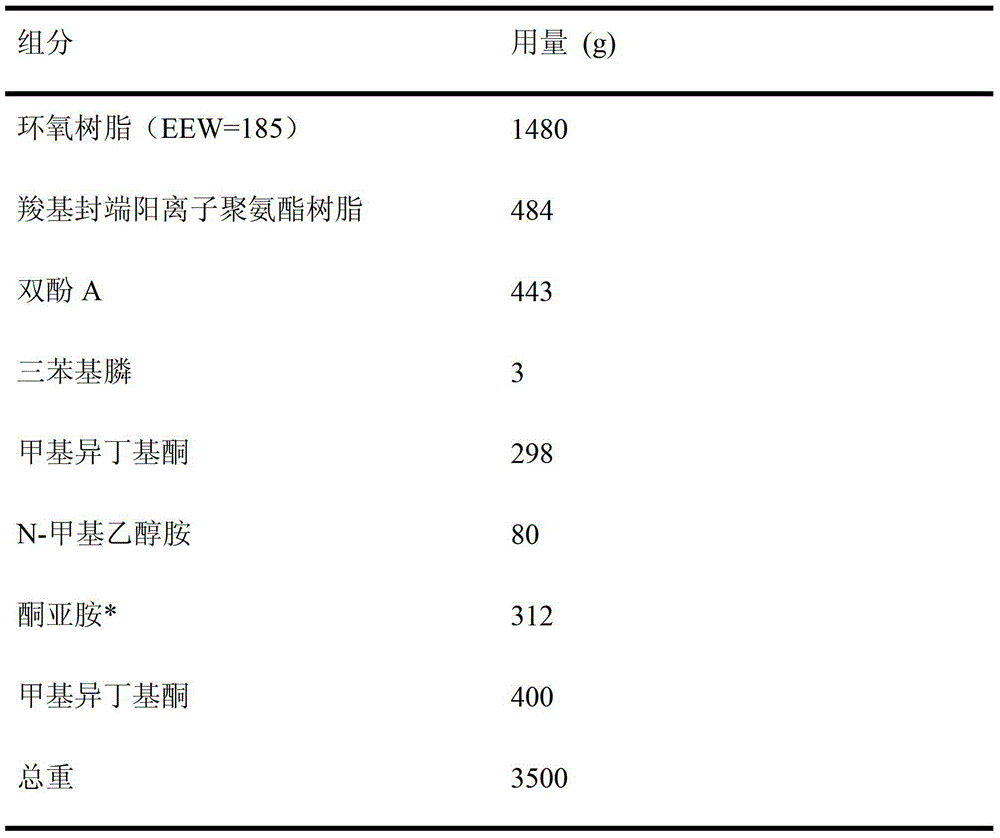

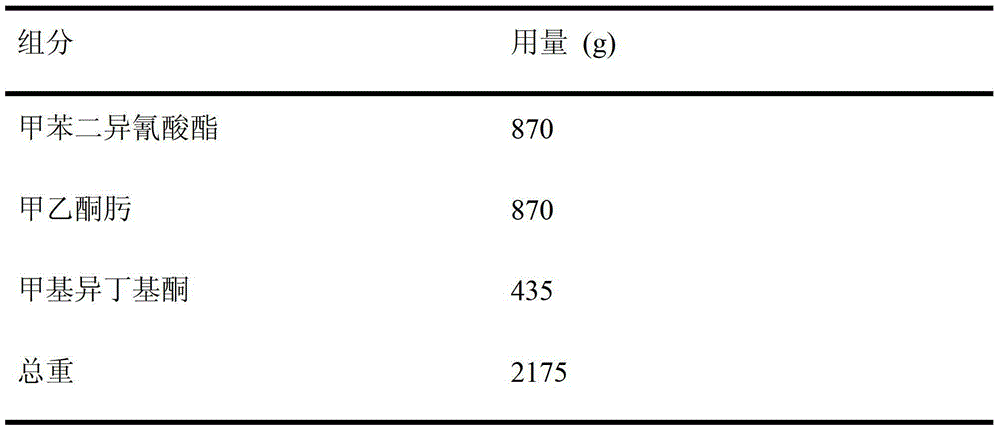

[0032] 2. Preparation of aminated ...

Embodiment 2

[0051] 1. Preparation of carboxyl-terminated cationic polyurethane resin

[0052]

[0053] *R 1 is butyl, R 4 is ethyl, R 2 and R 3 2-hydroxypropyl

[0054] **NCO / OH=3:1, hydrophilic group content: 9.14%

[0055] In a reaction flask equipped with a thermometer, a stirrer and a reflux condenser, sequentially add the formulated amount of isophorone diisocyanate and two polyether diols with different molecular weights, and react for 50 minutes after heating up to 80°C; then add butyl Diol, continue to react at the same temperature for 30 minutes; then add hydrophilic chain extender, continue to react at the same temperature for 35 minutes, and use standard di-n-butylamine back titration to analyze the content of isocyanate groups in the prepolymer. When the base content reaches the theoretical value of 15.62%, 6-aminocaproic acid is added for capping to obtain a carboxyl-terminated cationic polyurethane resin with an acid value of 140 mgKOH / g.

[0056] 2. Preparation of ...

Embodiment 3

[0067] 1. Preparation of carboxyl-terminated cationic polyurethane resin

[0068]

[0069]

[0070] *R 1 is ethyl, R 2 is hydroxyethyl, R 3 is 3-propoxy-2-hydroxypropyl, R 4 for butyl

[0071] **NCO / OH=2:1, hydrophilic group content: 3.84%

[0072] In a reaction flask equipped with a thermometer, a stirrer and a reflux condenser, sequentially add the prescribed amount of diphenylmethane diisocyanate and polyester diol, and react for 30 minutes after heating up to 60°C; then add hexanediol, and heat up to After 70°C, continue to react for 30 minutes; then add a hydrophilic chain extender, continue to react at the same temperature for 35 minutes, and then use the standard di-n-butylamine back titration method to analyze the isocyanate group content in the prepolymer. When the isocyanate group content reaches When the theoretical value was 7.60%, 2-mercaptobutyric acid was added for capping to obtain a carboxyl-terminated cationic polyurethane resin with an acid value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com