Color paste for cathode electrophoretic paint and preparation method of color paste

A cathodic electrophoresis and color paste technology, which is applied in the direction of electrophoretic coatings, pigment pastes, coatings, etc., can solve the problems of low stability, low uniformity of color paste, and poor performance of cathodic electrophoretic paint, etc., to achieve improved Uniformity and stability, and the effect of improving throwing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

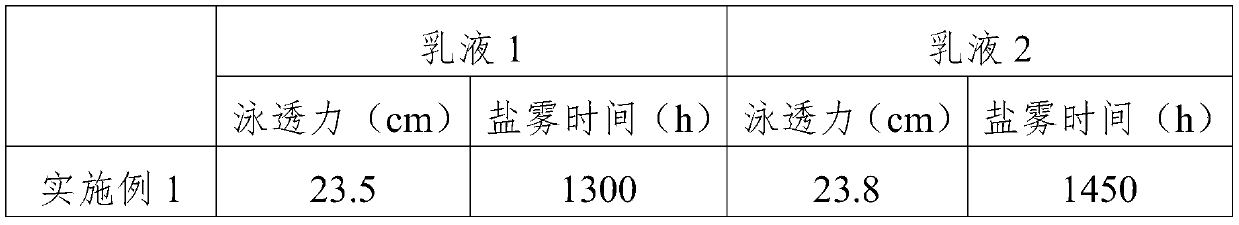

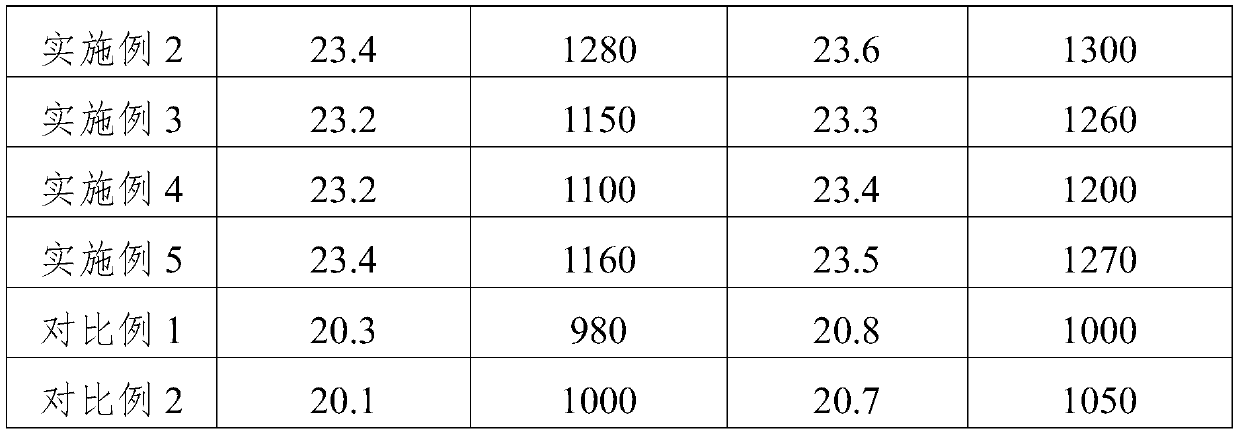

Examples

Embodiment 1

[0025] This embodiment provides a kind of color paste for cathodic electrophoretic paint, and the preparation method comprises the following steps:

[0026] Modification of epoxy resin with decylphenol: 500 parts of epoxy resin e-54, 125 parts of epoxy resin e-51, 63 parts of bisphenol, 125 parts of decylphenol, 70 parts of xylene, 5 parts of bisphenol Add methylbenzylamine into the reaction kettle one by one, react at 130°C, detect the epoxy value in the reaction system, when the epoxy value is 0.16, cool down to 90°C, add 100 parts of methyl isobutyl ketone, add 45 parts N-methylethanolamine was reacted at 90°C for 1 hour, 30 parts of monoethanolamine was added, reacted at 110±5°C for 3 hours, and the solvent was removed to obtain a decylphenol-modified epoxy resin.

[0027] Mix 20 parts of decylphenol-modified epoxy resin, 5 parts of ethylene glycol butyl ether, 5 parts of ethylene glycol and 3 parts of butanol evenly to obtain a mixed solution, add 1 part of carbon black t...

Embodiment 2

[0030] This embodiment provides a kind of color paste for cathodic electrophoretic paint, and the preparation method comprises the following steps:

[0031]Modification of epoxy resin with decylphenol: 500 parts of epoxy resin e-54, 125 parts of epoxy resin e-51, 63 parts of bisphenol, 125 parts of decylphenol, 70 parts of xylene, 5 parts of di Add methylbenzylamine into the reaction kettle in turn, react at 130°C, detect the epoxy value in the reaction system, when the epoxy value is 0.16, cool down to 90°C, add 100 parts of methyl isobutyl ketone, add 45 parts N-methylethanolamine was reacted at 90°C for 1 hour, 30 parts of monoethanolamine was added, reacted at 110±5°C for 3 hours, and the solvent was removed to obtain a decylphenol-modified epoxy resin.

[0032] Mix 25 parts of decylphenol-modified epoxy resin, 6 parts of ethylene glycol butyl ether, 6 parts of ethylene glycol and 4 parts of butanol evenly to obtain a mixed solution, add 1.2 parts of carbon black to the mi...

Embodiment 3

[0035] This embodiment provides a kind of color paste for cathodic electrophoretic paint, and the preparation method comprises the following steps:

[0036] Modification of epoxy resin with decylphenol: 500 parts of epoxy resin e-54, 125 parts of epoxy resin e-51, 63 parts of bisphenol, 125 parts of decylphenol, 70 parts of xylene, 5 parts of di Add methylbenzylamine into the reaction kettle in turn, react at 130°C, detect the epoxy value in the reaction system, when the epoxy value is 0.16, cool down to 90°C, add 100 parts of methyl isobutyl ketone, add 45 parts N-methylethanolamine was reacted at 90°C for 1 hour, 30 parts of monoethanolamine was added, reacted at 110±5°C for 3 hours, and the solvent was removed to obtain a decylphenol-modified epoxy resin.

[0037] Mix 15 parts of decylphenol-modified epoxy resin, 3 parts of ethylene glycol butyl ether, 3 parts of ethylene glycol and 1 part of butanol evenly to obtain a mixed solution, add 0.5 parts of carbon black to the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com