Emulsion resin for high-humidity film resistance cathodic electrophoretic coating and preparation method thereof

A cathodic electrophoretic coating, membrane resistance technology, applied in electrophoretic coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as use surface limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

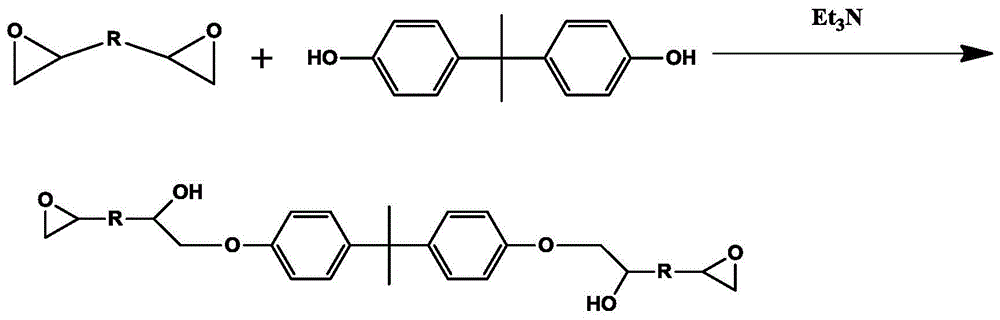

[0034] Preparation of bisphenol A type epoxy resin:

[0035] First add inert organic solvent, bisphenol A and organic base to the basic epoxy resin, heat up to 100-150°C under constant stirring, keep warm for 1-2 hours, cool down and discharge, the basic epoxy resin is catalyzed by the organic base and Bisphenol A undergoes a chain extension reaction to obtain an epoxy resin with an epoxy equivalent of 300-2000, and put it in a clean and sealed container for later use. The organic base catalyst can be triethylamine, N-N dimethylbenzylamine, triethanolamine , Dimethylethanolamine, triphenylphosphine, methyldiethanolamine. The reaction formula is as follows:

[0036]

[0037] The specific formula is as follows:

[0038] Substance name Parts (parts by mass) 128 resin 690 Bisphenol A 210

[0039] Triethylamine 1 Xylene 110

[0040] In a four-neck flask equipped with a thermometer, a stirring paddle, and a condenser tube, add 1...

Embodiment 2

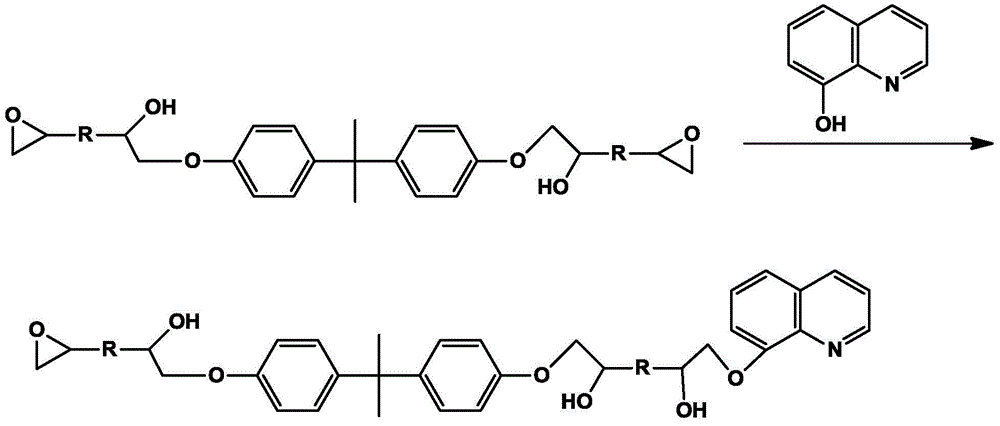

[0042] The epoxy resin containing quinoline structure prepared by bisphenol A type epoxy resin and 8-hydroxyquinoline:

[0043] Add bisphenol A type epoxy resin into an inert organic solvent, raise the temperature to 115-125°C under constant stirring, add 8-hydroxyquinoline, raise the temperature to 120-130°C after the addition, keep it warm for 3 hours, then cool down and discharge the material to obtain expanded 8-hydroxyquinoline modified bisphenol A epoxy resin after the chain.

[0044] The inert organic solvent can be an alcohol solvent, an alcohol ether solvent, a toluene solvent or a ketone solvent, wherein the alcohol solvent can be selected from isopropanol, n-butanol, isobutanol, n-hexanol, isooctyl alcohol, etc. Alcohol ether solvents can choose ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, ethylene glycol butyl ether, ethylene glycol hexyl ether, diethylene glycol butyl ether, propylene glycol methyl ether, toluene solvents can choose toluene, ...

Embodiment 3

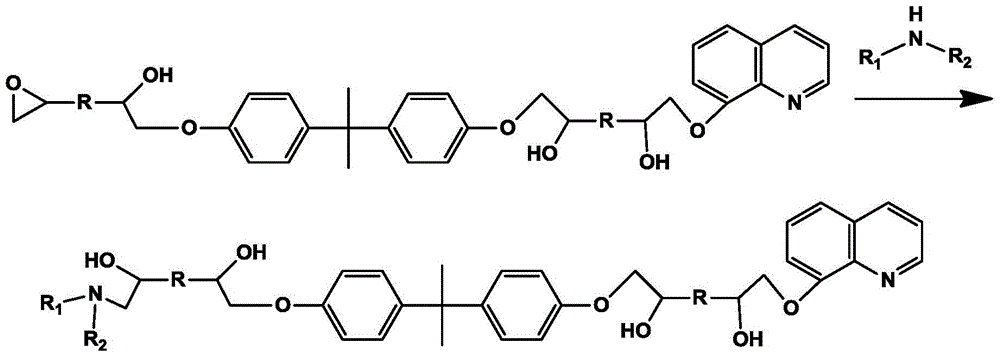

[0050] Amine modification of epoxy resin containing quinoline structure:

[0051]Add the epoxy resin containing quinoline structure to an inert organic solvent, raise the temperature to 75-85°C under constant stirring, add the amine-modified compound containing active hydrogen, raise the temperature to 100-120°C after adding, keep it warm for 3 hours and then cool down Discharging, to obtain functional modified epoxy resin A, put into a clean and sealed container for subsequent use, the amount of the amine-modified compound containing active hydrogen accounts for 70% of the total amount of epoxy groups according to active hydrogen- 80%, the selected monovalent secondary amines can be alkylamines, ketimines, alcoholamines, etc. or their mixtures, wherein the alkylamines can be diethylamine, methylisobutylamine, dibutylamine Base amines, ketimines can choose hydroxymethyl ethylenediamine ketimines, diethylenetriamine ketimines, alcohol amines can choose diethanolamine, methyleth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com