Detent-type soil anchor rod and application thereof

A technology of soil layer and anchor rod, which is applied in the direction of sheet pile wall, excavation, construction, etc., can solve the problems that it is difficult to achieve the expected effect, the difficulty of forming holes in anchor rod construction, and the low bonding force of soil layer anchor rods, etc., to achieve improved Strong binding force, convenient construction, and increased pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

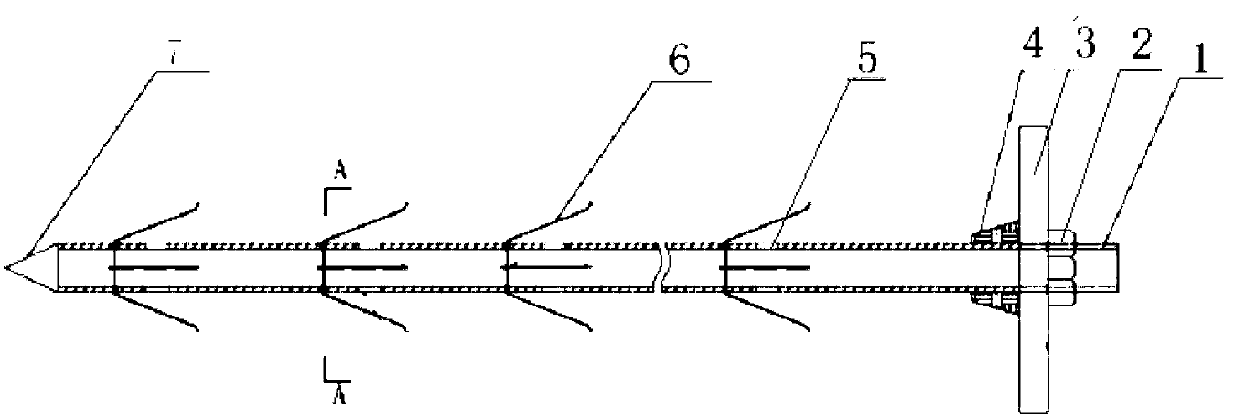

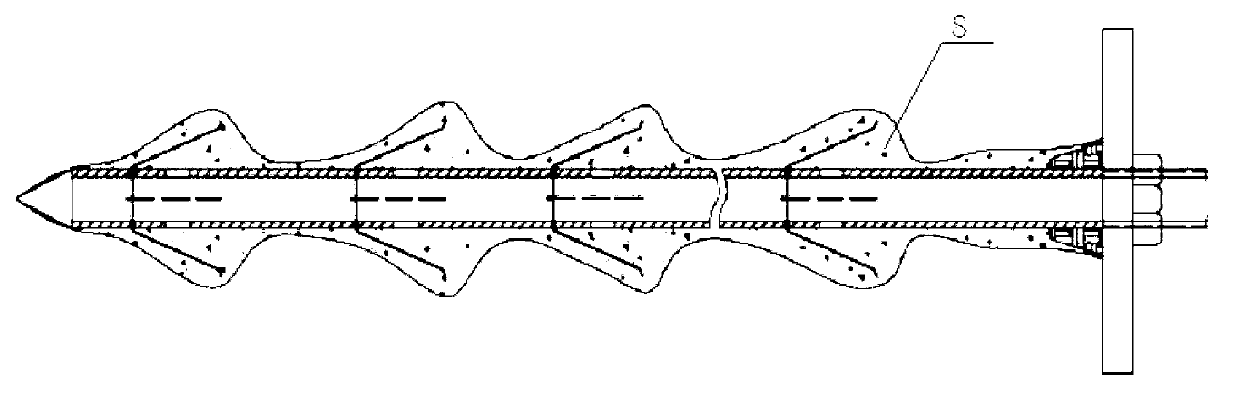

[0022] like figure 1 The pawl type soil anchor shown in the figure comprises a steel pipe 1, the rear end of the steel pipe 1 is provided with an external thread, and is equipped with a grout stopper 4, a tray 3 and a nut 2, wherein the steel pipe 1 is spaced at a certain interval. A grouting hole 5 is provided at a distance, and a steel wire ratchet 6 is provided on the wall of the steel pipe 1 between the grouting holes, and a tapered closing cap 7 is provided at the front end of the steel pipe 1 .

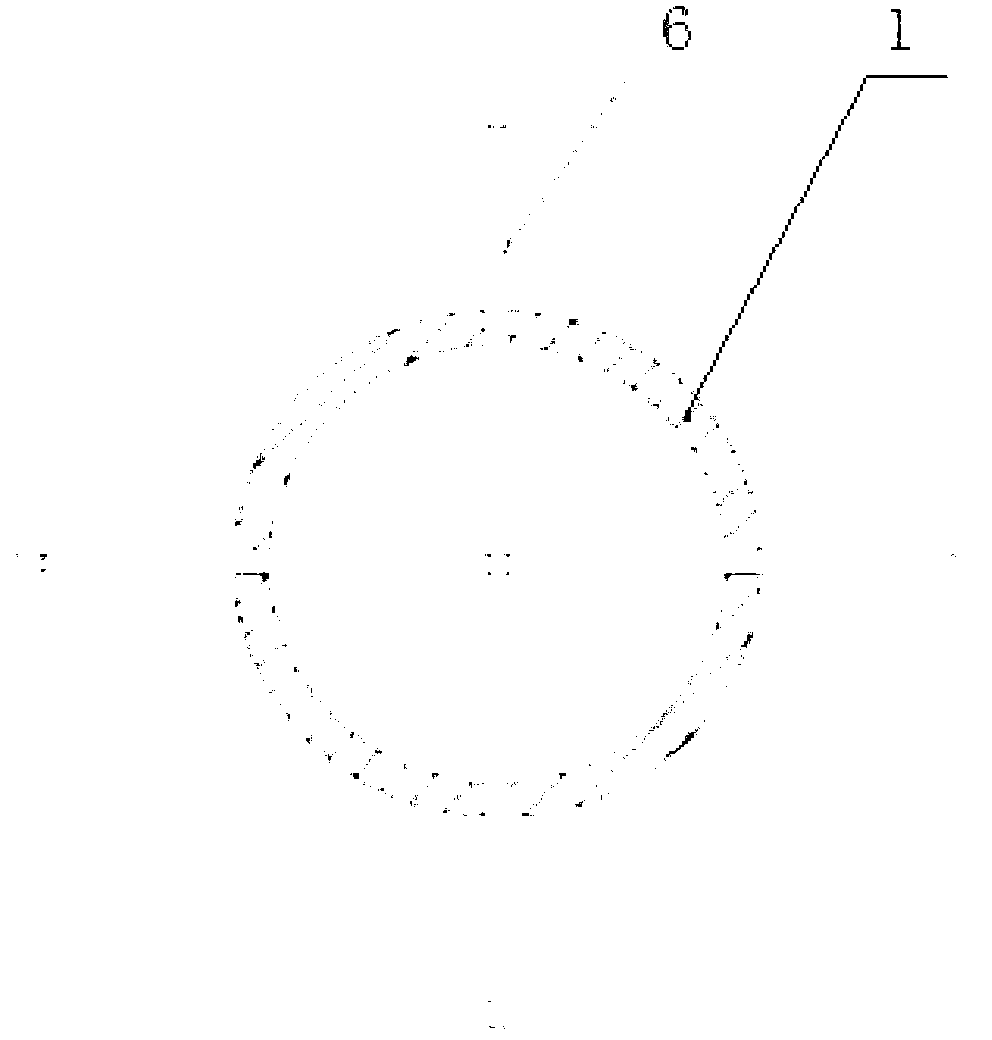

[0023] The structure of wire ratchet 6 is as figure 1 , figure 2 As shown: the steel pipe 1 is processed with a pair of perforations, and a steel bar is inserted into the pair of holes, and the two ends of the steel bar are exposed from the pair of holes and then bent obliquely rearward to form a figure-eight shape. from figure 2 It can be seen that: on the same section of the steel pipe 1, two criss-cross steel bars are penetrated, so that the four directions of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com