Drilling machine integrated double-loop network coupling control system based on IPC and PLC

A dual-loop network, coupled control technology, applied in the automatic control system of drilling, drilling equipment, earthwork drilling, etc. Avoid major economic losses, realize remote monitoring and control, and realize the effect of remote centralized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

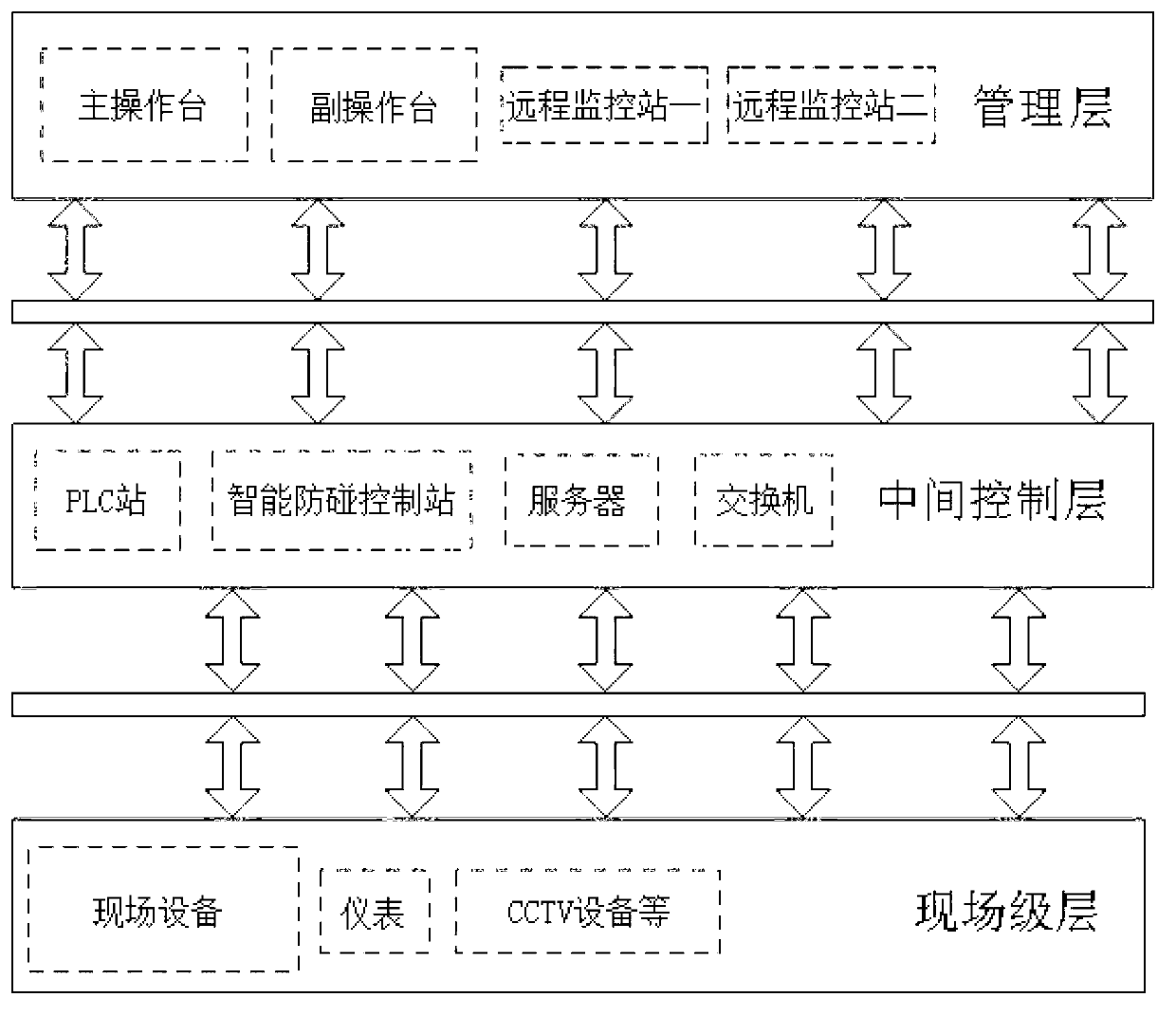

[0038] refer to figure 1 , the present invention is based on the IPC and PLC integrated double-loop network coupling control system for drilling rigs (hereinafter referred to as the integrated control system), which consists of three layers of structure: one is the field level (including field equipment, instruments, CCTV equipment, etc.), the other is the intermediate The control layer (including PLC station, intelligent anti-collision control station, server, switch, etc.), the third is the management layer (including the main operation console, auxiliary operation console and multiple remote monitoring stations).

[0039] In the management layer, the main operating console and the auxiliary operating console are responsible for monitoring and controlling each field device; each remote monitoring station can realize online monitoring of fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com