Fabry-Perot sensor capable of simultaneously detecting double parameters and detection device

A Fa-Per sensor, dual-parameter technology, applied in the coupling of measurement devices, instruments, optical waveguides, etc., can solve problems such as the influence of detection sensitivity, and achieve the effect of easy fully programmed operation and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

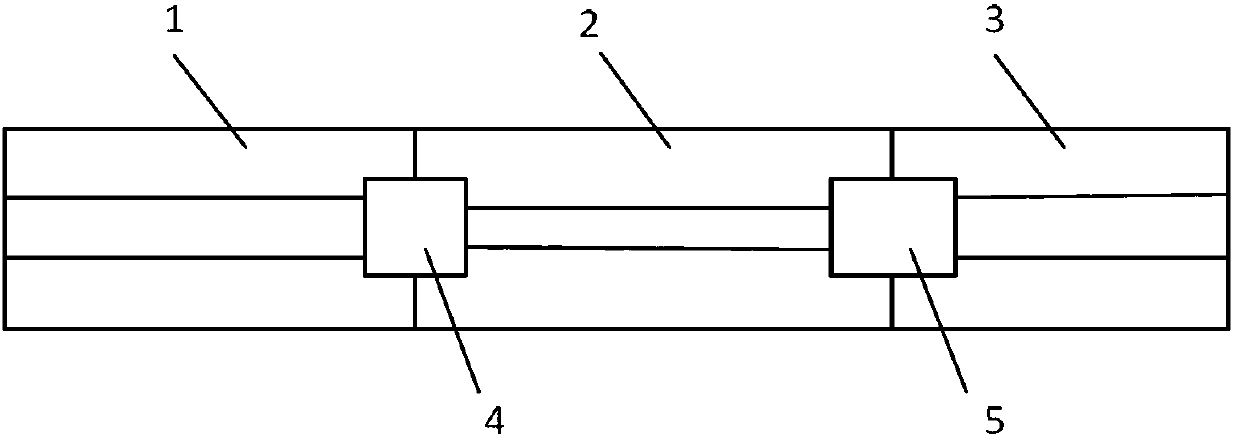

[0016] Such as figure 1 As shown, in the present embodiment, a Fab sensor based on photonic crystal fiber micromachining, the sensor is welded by the first single-mode fiber 1, the photonic crystal fiber 2 and the second single-mode fiber 3 in sequence, and after fusion, passes through Femtosecond laser processing, excimer laser processing, or plasma beam etching are used to process two Fab cavities with different cavity lengths at the fusion joint. Wherein, the length of the photonic crystal fiber 2 is greater than 500 micrometers, so as to prevent crosstalk between two Fab cavities. The lengths of the first and the second Fapp cavity are respectively 40-100 microns, and the length difference between them is 10-20 microns.

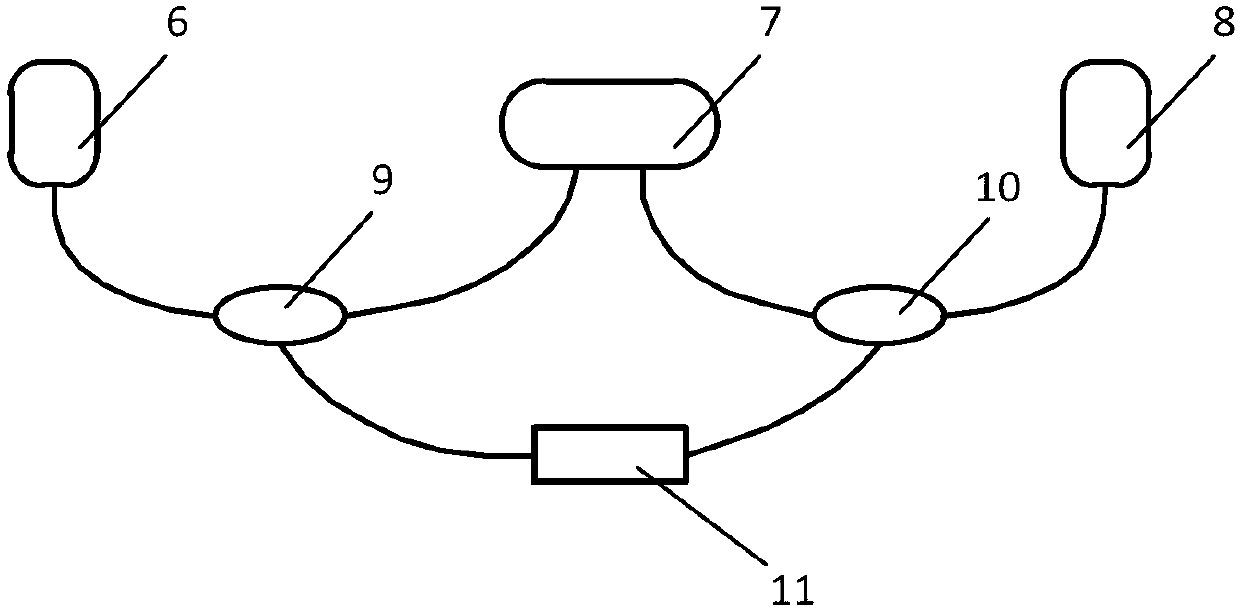

[0017] figure 2 Shown is the measuring device that adopts the Fap sensor based on photonic crystal fiber micromachining of the present invention, it comprises the first broadband light source 6, spectrometer 7, the second broadband light source 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com