Manufacturing method for high-pressure tank, and high-pressure tank

A manufacturing method and technology of high-pressure tanks, applied in the field of high-pressure tanks, to achieve the effects of extending cruising range, reducing size, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0031] A. Structure of high pressure tank

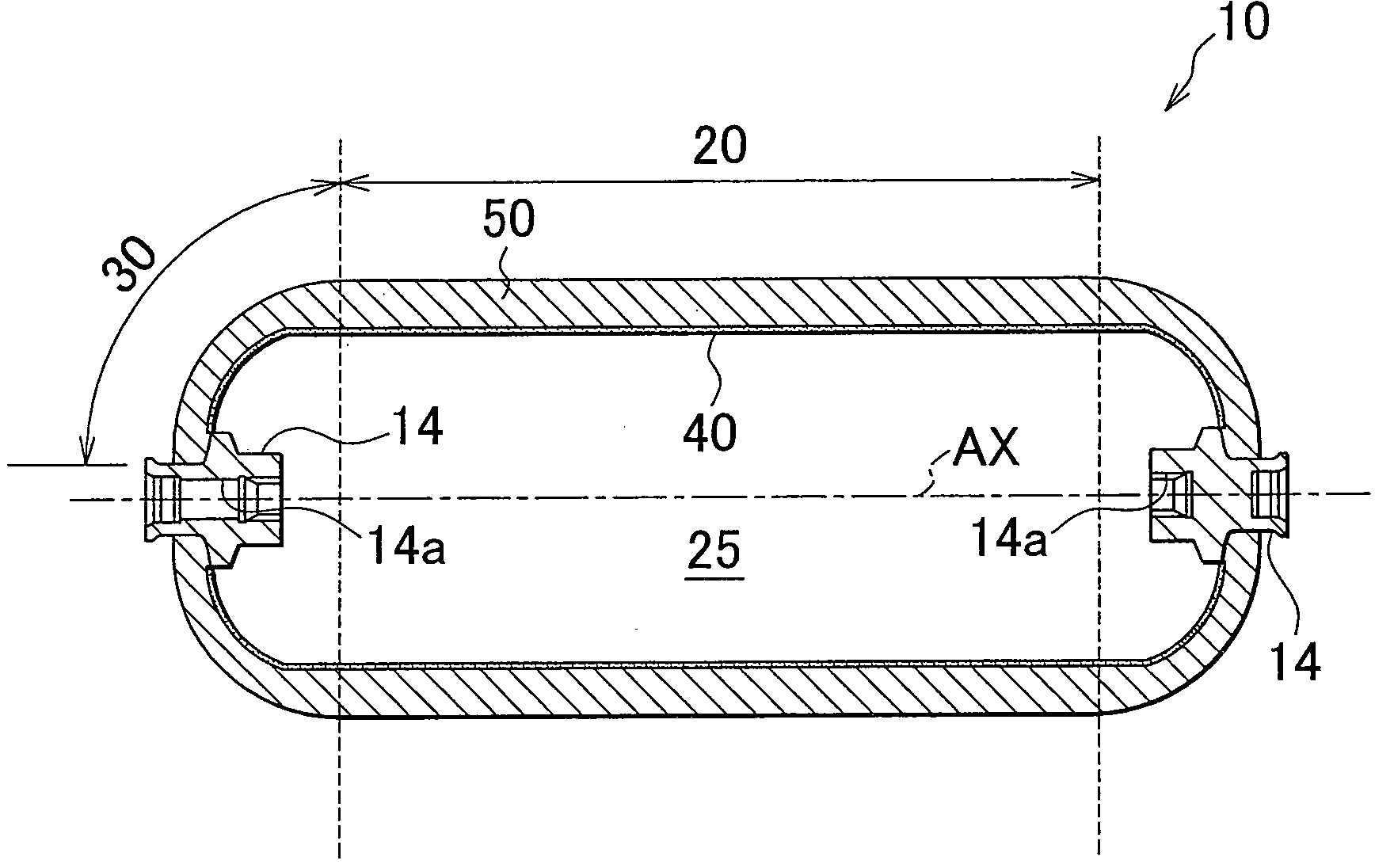

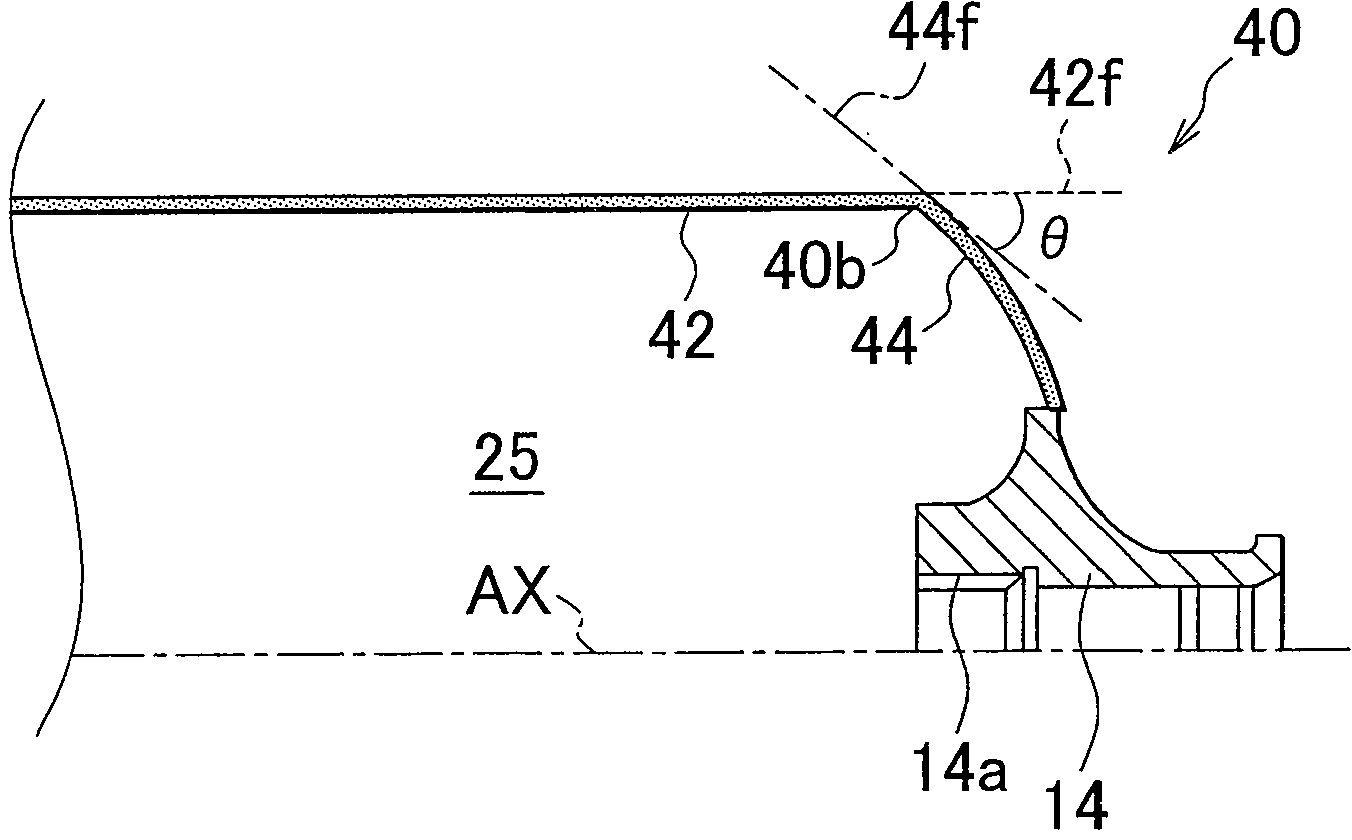

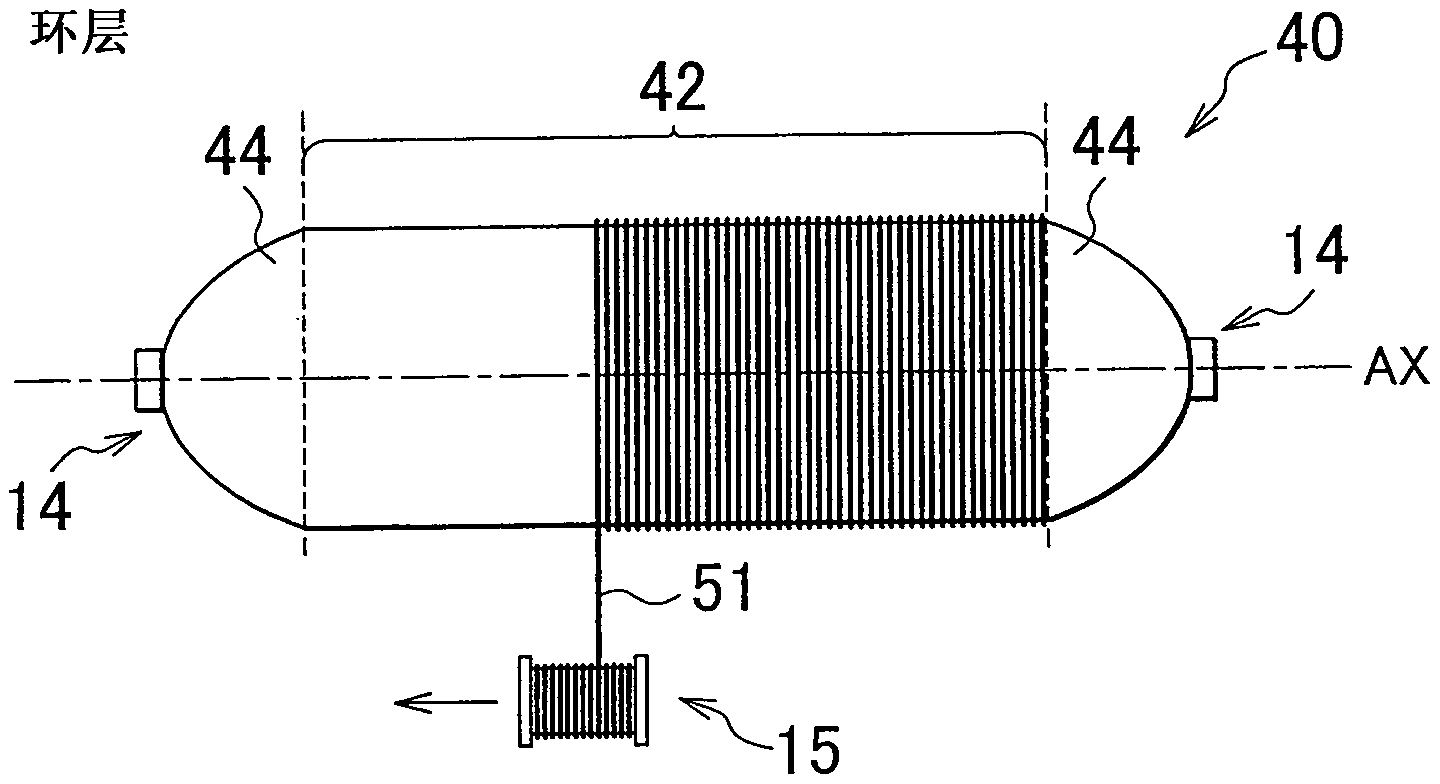

[0032] Figure 1A and Figure 1B is a view illustrating a schematic configuration of the high-pressure tank 10 according to the embodiment of the present invention. Figure 1A A cross-sectional view of the high pressure tank 10 is shown. in addition, Figure 1B Shows Figure 1A A partially enlarged view of . Note that in Figure 1B In , illustration of the fiber-reinforced plastic layer 50 (to be described later) is omitted.

[0033] as in Figure 1A As shown in , a high pressure tank 10 includes a liner 40 , a fiber reinforced plastic layer 50 and two end fittings 14 . A fiber reinforced plastic layer 50 covers the surface of the liner 40 . Each end fitting 14 has an opening 14a. Note that in the present embodiment, the high-pressure tank 10 includes two end fittings 14 ; alternatively, the high-pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com