Method for maintaining and building 320-ton torpedo ladle cone working layer

A technology of working layers and torpedo tanks, applied in the direction of manufacturing tools, metal processing equipment, casting melt containers, etc., can solve the problems of long construction period, reduced maintenance workload, large consumption of refractory materials, etc., and achieve shortened maintenance period and maintenance work The effect of reducing the quantity and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The maintenance and masonry of the 320-ton torpedo tank cone working layer is carried out in accordance with the following steps:

[0030] 1) When the torpedo tank needs to be overhauled, the working layer should be cleaned first, and the residual thickness of the working layer should be kept at 80mm;

[0031] 2) Use aluminum silicon carbide cement and add water to smooth the working layer; the ratio of aluminum silicon carbide cement to water is 100:26;

[0032] 3) Dry the flattened working layer naturally for 24 hours;

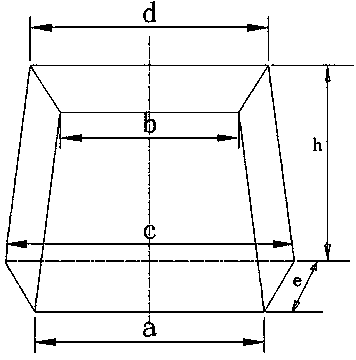

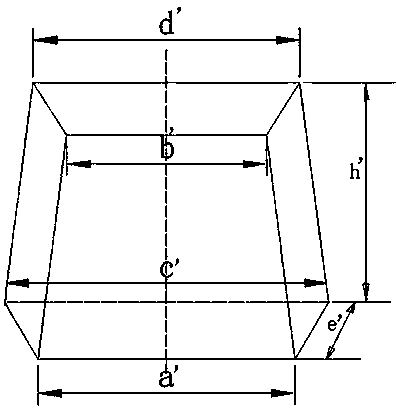

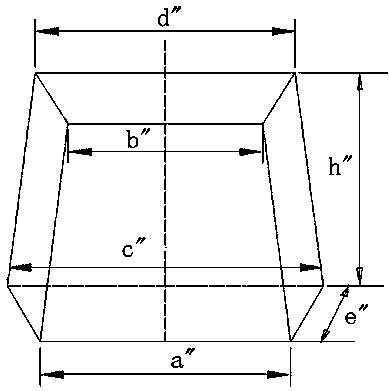

[0033] 4) Build the refractory brick layer according to the conventional method. The refractory bricks are of the same structure and have different sizes. Special-shaped one, special-shaped two and special-shaped three are used for coordinating masonry, and the pieces are listed in Table 1; each ring is built to the center with lock bricks Close the door; the masonry is all wet masonry, the mud fullness is 96%, the brick joint is not more than 2mm an...

Embodiment 2

[0042] The maintenance and masonry of the 320-ton torpedo tank cone working layer is carried out in accordance with the following steps:

[0043] 1) When the torpedo tank needs to be overhauled, the working layer should be cleaned first, and the residual thickness of the working layer should be kept at 82mm;

[0044] 2) Use aluminum silicon carbide cement and add water to smooth the working layer; the ratio of aluminum silicon carbide cement to water is 100:26;

[0045] 3) Dry the flattened working layer naturally, and the drying time is 24.5 hours;

[0046] 4) Build the refractory brick layer according to the conventional method. The refractory bricks are of the same structure and have different sizes. Special-shaped one, special-shaped two and special-shaped three are used for coordinating masonry, and the pieces are listed in Table 1; each ring is built to the center with lock bricks Close the door; the masonry is all wet masonry, the mud fullness is 96%, the brick joint i...

Embodiment 3

[0055] The maintenance and masonry of the 320-ton torpedo tank cone working layer is carried out in accordance with the following steps:

[0056]1) When the torpedo tank needs to be overhauled, the working layer should be cleaned first, and the residual thickness of the working layer should be kept at 85mm;

[0057] 2) Use aluminum silicon carbide cement and add water to smooth the working layer; the ratio of aluminum silicon carbide cement to water is 100:26;

[0058] 3) Dry the flattened working layer naturally for 25 hours;

[0059] 4) Build the refractory brick layer according to the conventional method. The refractory bricks are of the same structure and have different sizes. Special-shaped one, special-shaped two and special-shaped three are used for coordinating masonry, and the pieces are listed in Table 1; each ring is built to the center with lock bricks Close the door; the masonry is all wet masonry, the mud fullness is 96%, the brick joint is not more than 2mm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com