Polymer supercritical mould pressing foaming mould

A foaming mold and polymer technology, applied in the field of polymer supercritical molding foaming mold, can solve the problems of long production cycle, achieve the effects of preventing polymer backflow, shortening production cycle, and improving injection and dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

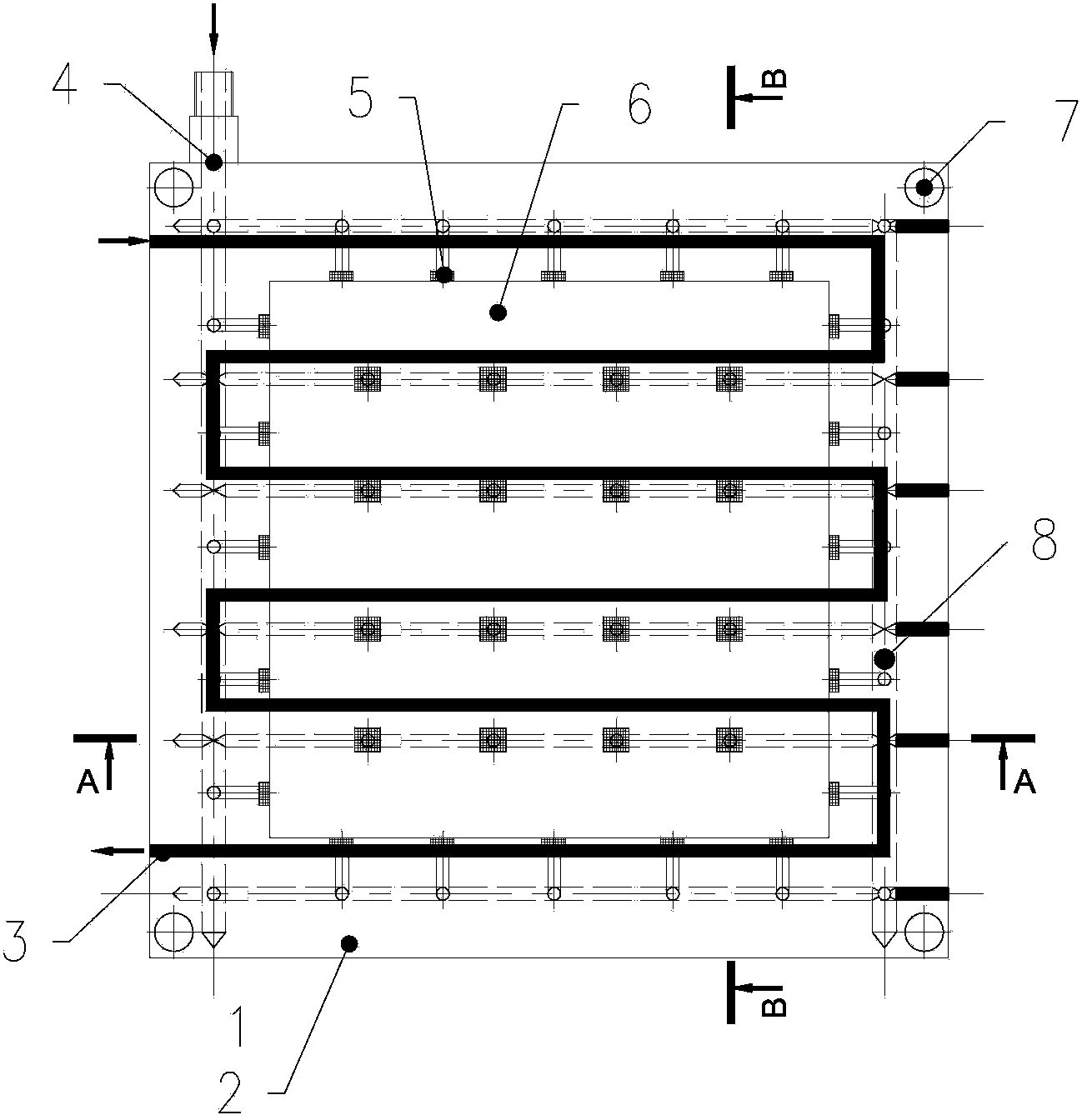

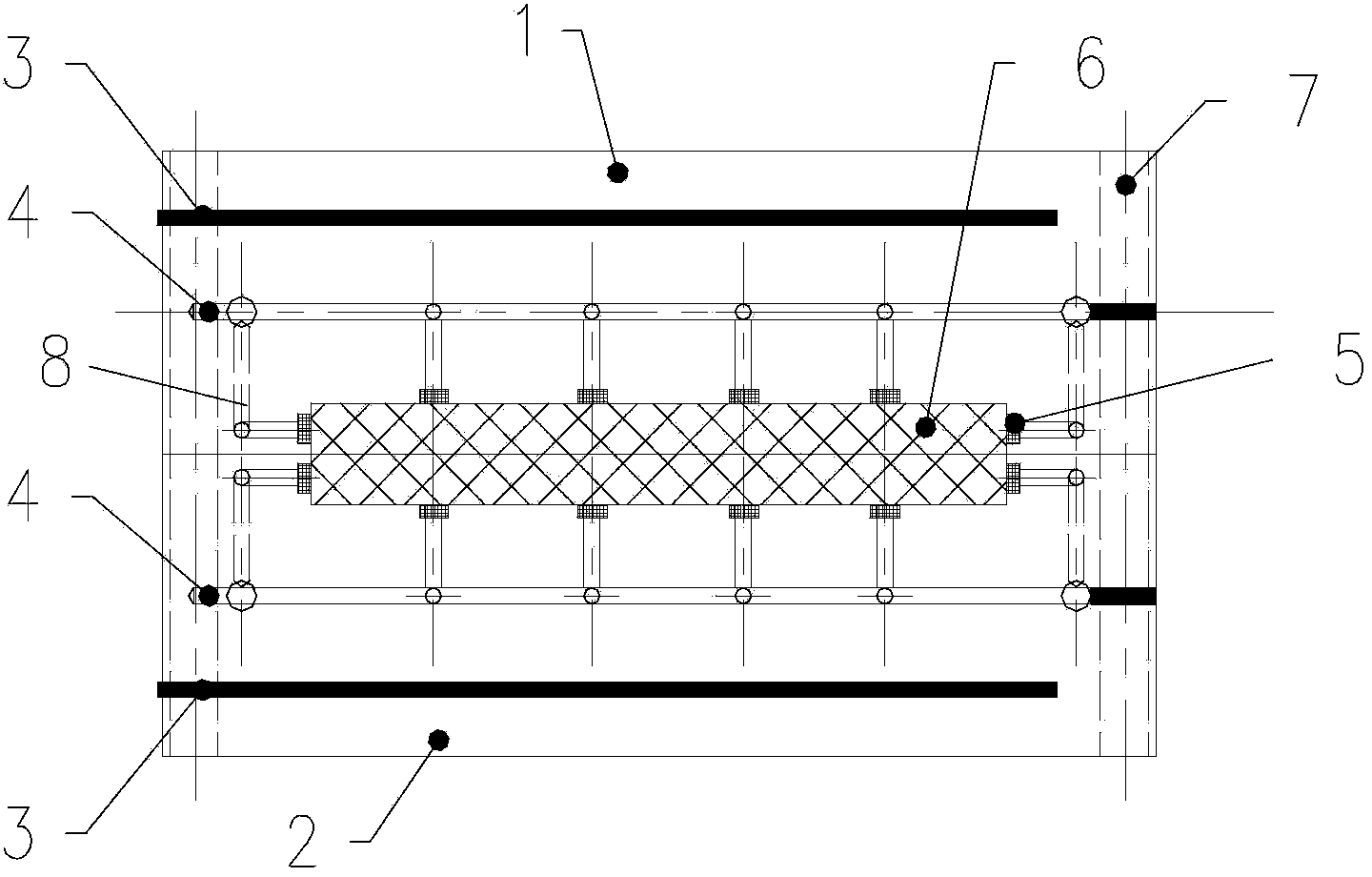

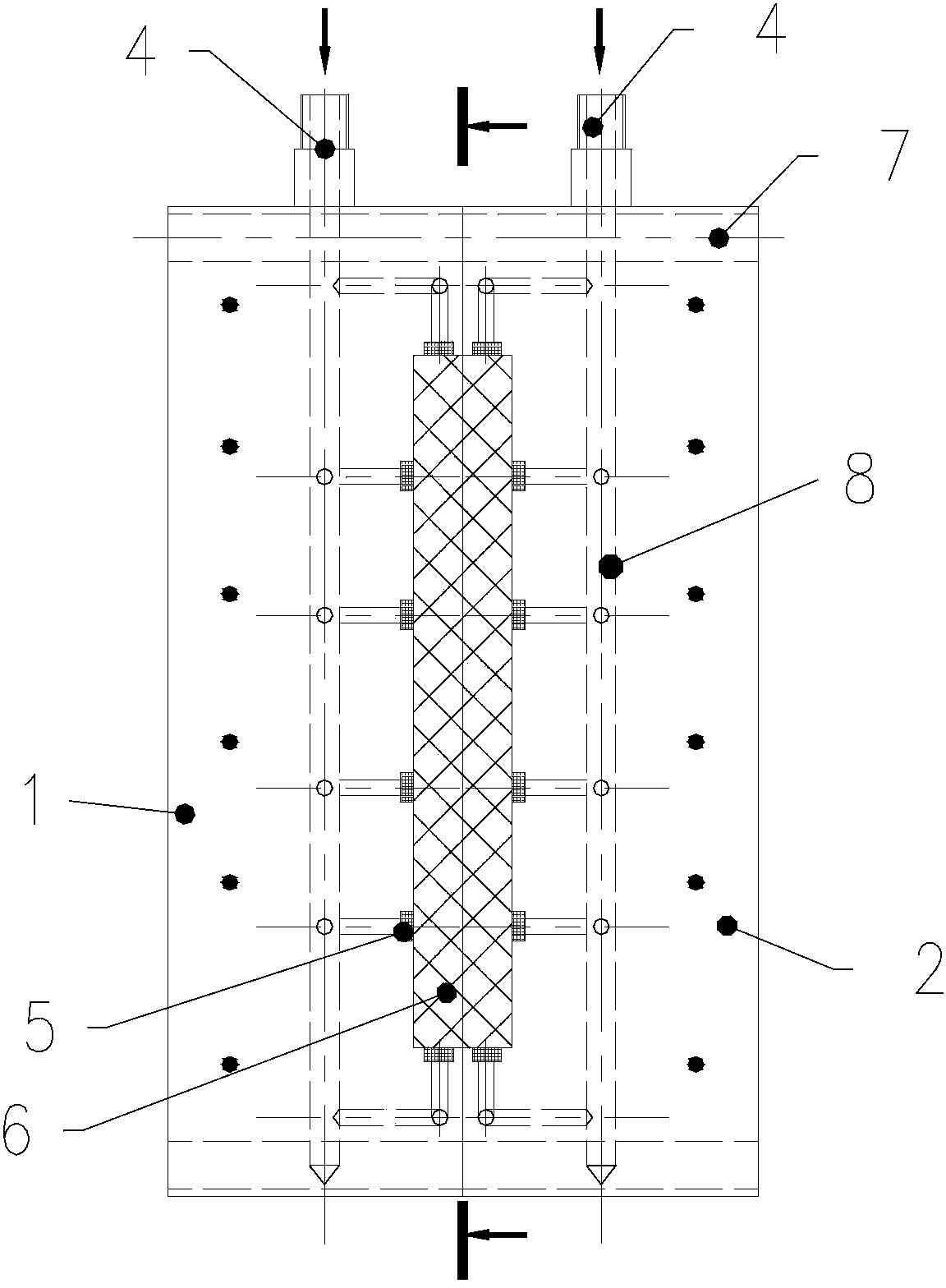

[0012] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 3 As shown, the present invention mainly includes an upper mold 1 and a lower mold 2. The temperature of the mold can be controlled within 50-300°C. The molding machine is driven to move up and down, so as to open the mold and lock it. A mold cavity 6 for placing polymers is provided between the upper mold 1 and the lower mold 2; a several-shaped oil passage 3 is arranged in the upper mold 1 and the lower mold 2. In the described mold cavity 6, a plurality of supercritical fluid injection ports 4 are provided on the upper, lower, front, rear, left, and right sides. Metal sintered filter block 5. The mold can be a one-layer or multi-layer structure, capable of producing multiple products at one time.

[0013] The working principle of the present invention is as follows: during production, the heat conduction oil at a temperature of 50-500 degrees is firstly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com