Solid hydrogen peroxide preparation technology

A solid hydrogen peroxide, preparation technology, applied in bleaching products, textiles and papermaking, non-surfactant detergent composition, etc., can solve the problems of insufficient utilization of mother liquor and high production cost, achieve low cost, short process cycle, overcome The effect of higher production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

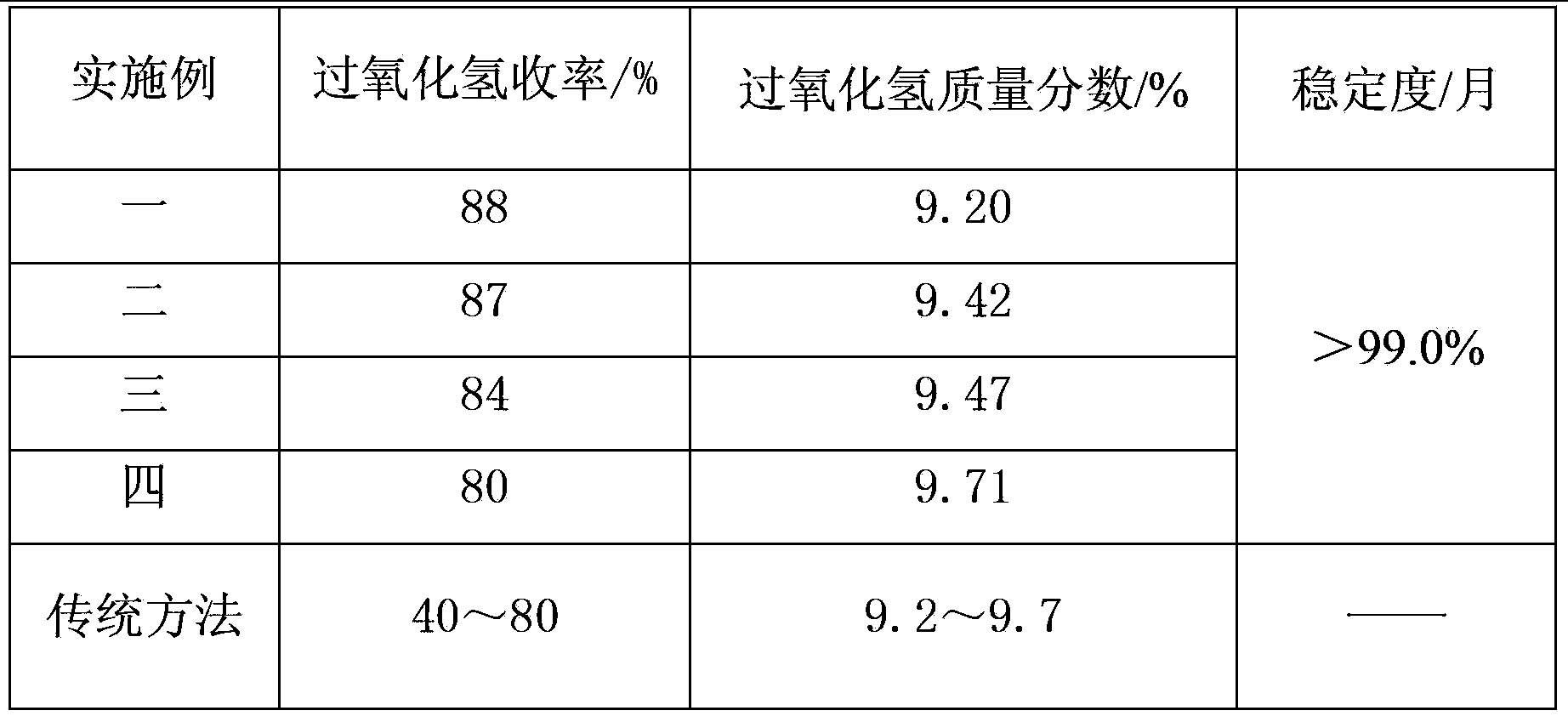

Examples

Embodiment 1

[0019] A kind of solid hydrogen peroxide preparation process has the following steps:

[0020] (1) Prepare sodium sulfate, hydrogen peroxide and sodium chloride at a molar ratio of 4:2.1:1, knead the mixture of sodium sulfate and sodium chloride in a kneader until there are no lumps, and the mass fraction of hydrogen peroxide is 30 %;

[0021] (2) Spray hydrogen peroxide into the above mixture three times within 60 minutes, and at the same time, continue to knead and mix the compound of sodium sulfate, hydrogen peroxide and sodium chloride until there is no agglomeration;

[0022] (3) Put the mixture obtained in step (2) in an oven and dry at 35°C for 60 minutes to obtain the finished product. Embodiment two

Embodiment 2

[0023] A kind of solid hydrogen peroxide preparation process has the following steps:

[0024] (1) Prepare sodium sulfate, hydrogen peroxide and sodium chloride at a molar ratio of 4:2.2:1, knead the mixture of sodium sulfate and sodium chloride in a kneader until there is no lump;

[0025] (2) Spray hydrogen peroxide into the above mixture three times within 70 minutes, and at the same time, continue to knead and mix the compound of sodium sulfate, hydrogen peroxide and sodium chloride until there is no agglomeration;

[0026] (3) Place the mixture obtained in step (2) in an oven and dry at 40°C for 45 minutes to obtain the finished product. Embodiment three

Embodiment 3

[0027] A kind of solid hydrogen peroxide preparation process has the following steps:

[0028] (1) Prepare sodium sulfate, hydrogen peroxide and sodium chloride at a molar ratio of 4:2.3:1, knead the mixture of sodium sulfate and sodium chloride in a kneader until there is no lump;

[0029] (2) Spray hydrogen peroxide into the above mixture 4 times within 90 minutes, and at the same time, continue to knead and mix the compound of sodium sulfate, hydrogen peroxide and sodium chloride until there is no agglomeration;

[0030] (3) Place the mixture obtained in step (2) in an oven and dry at 50°C for 30 minutes to obtain the finished product. Embodiment four

[0031] A kind of solid hydrogen peroxide preparation process has the following steps:

[0032] (1) Prepare sodium sulfate, hydrogen peroxide and sodium chloride at a molar ratio of 4:2.5:1, knead the mixture of sodium sulfate and sodium chloride in a kneader until there are no lumps;

[0033] (2) Spray hydrogen peroxide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com