Pneumatic material feeding type automatic slag adding machine

A pneumatic feeding and slag adding machine technology, applied in the field of continuous casting production auxiliary equipment, can solve the problems of affecting the production environment, long emptying time of the material box, difficult maintenance, etc., and achieve the protection of the site environment, the same protection performance, and the equipment structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

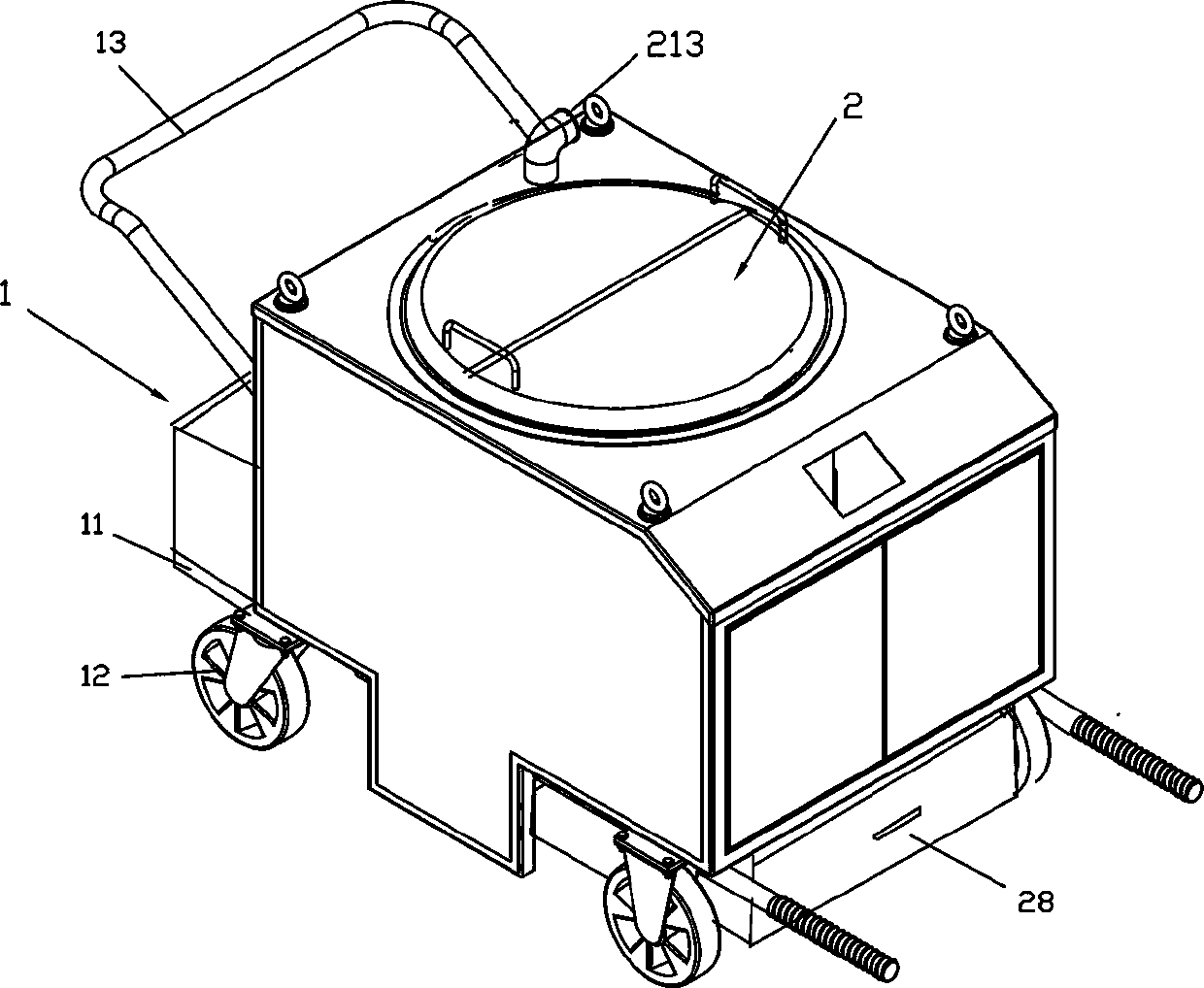

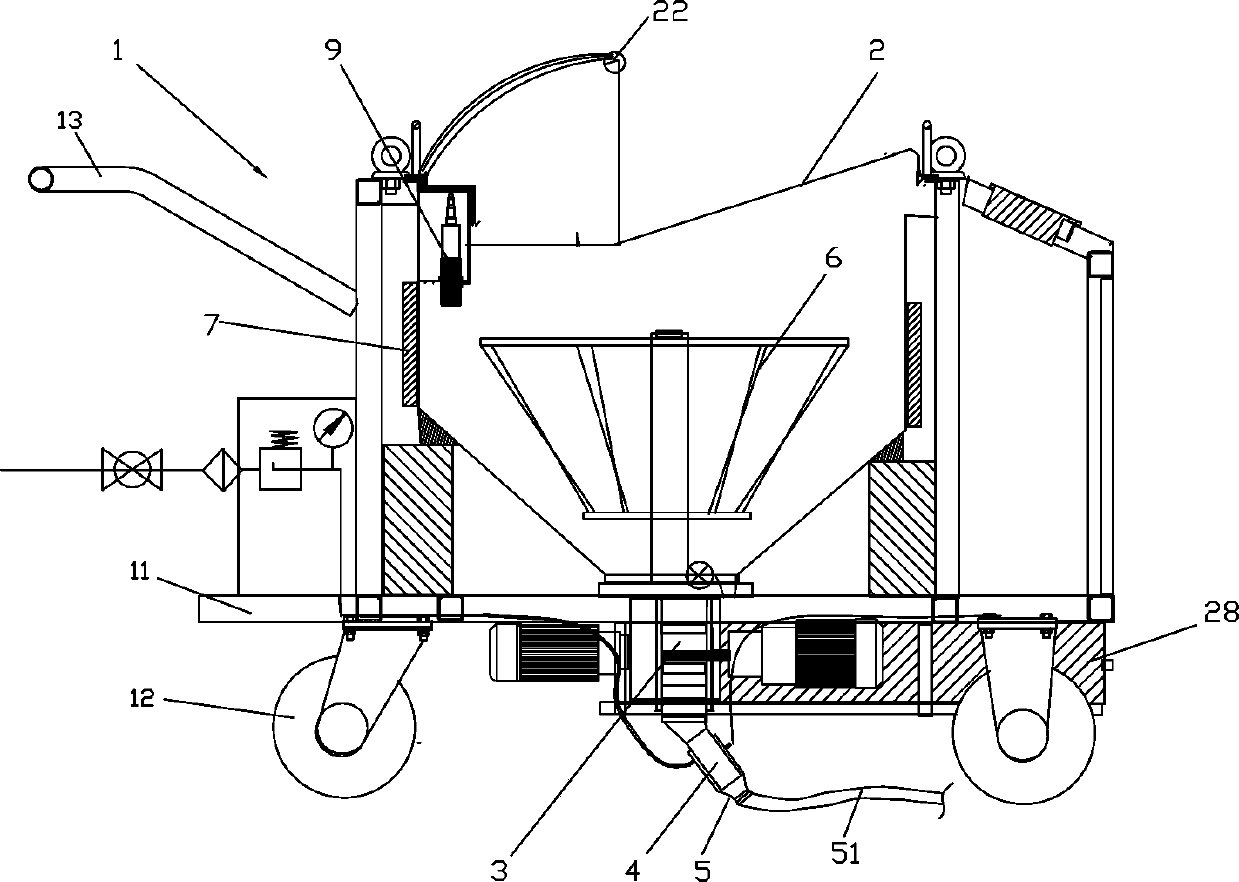

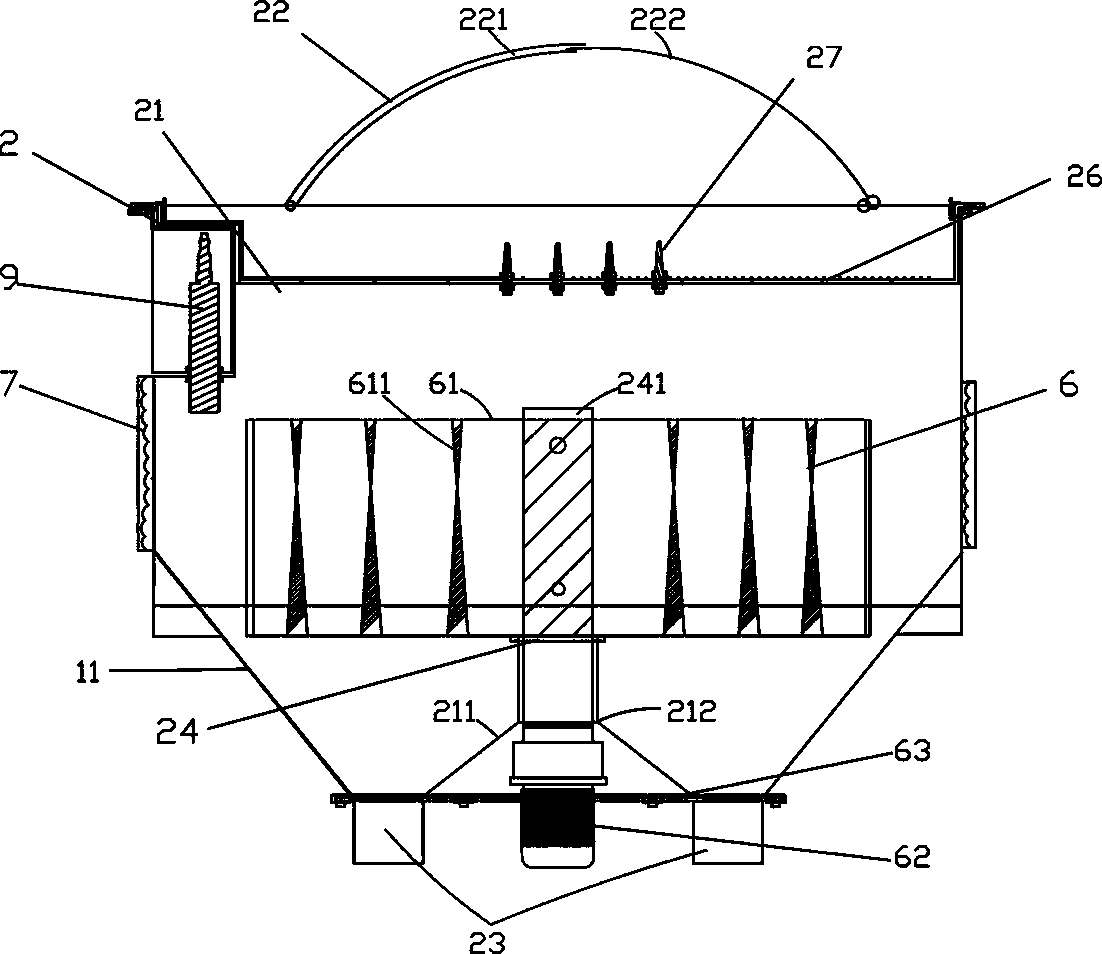

[0051] see Figure 1 to Figure 13 , a kind of pneumatic feeding type slag adding machine of the present invention, it comprises, slag material trolley 1, comprises car body 11, is provided with four wheels 12 and handle 13 on it; 1 On the vehicle body 11, a material box cover is arranged on the material box 2, the lower part of the material box is conical, and at least one discharge port is provided at the bottom; at least one metering pump 3 is correspondingly arranged below the material box discharge port; the slag blowing device 4, its inlet is correspondingly arranged on the feeding pipe at the outlet of the metering pump 3, and the mixing pipe 5 is correspondingly arranged below the outlet of the slag blower 4, and is connected to the material distribution pipe of the crystallizer through the connecting hose 51 Connection; Stirring mechanism 6, including stirring member 61 and its driving motor 62; Stirring member 61 is arranged in the lower part of material box 2; Operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com