Sawing machine

A sawing machine and chainsaw technology, applied in the field of sawing machines, can solve the problems of discontinuous cutting surface of wood, discontinuous movement of chainsaw, inability to cut wood, etc., so as to reduce the use of labor, increase market competitiveness, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

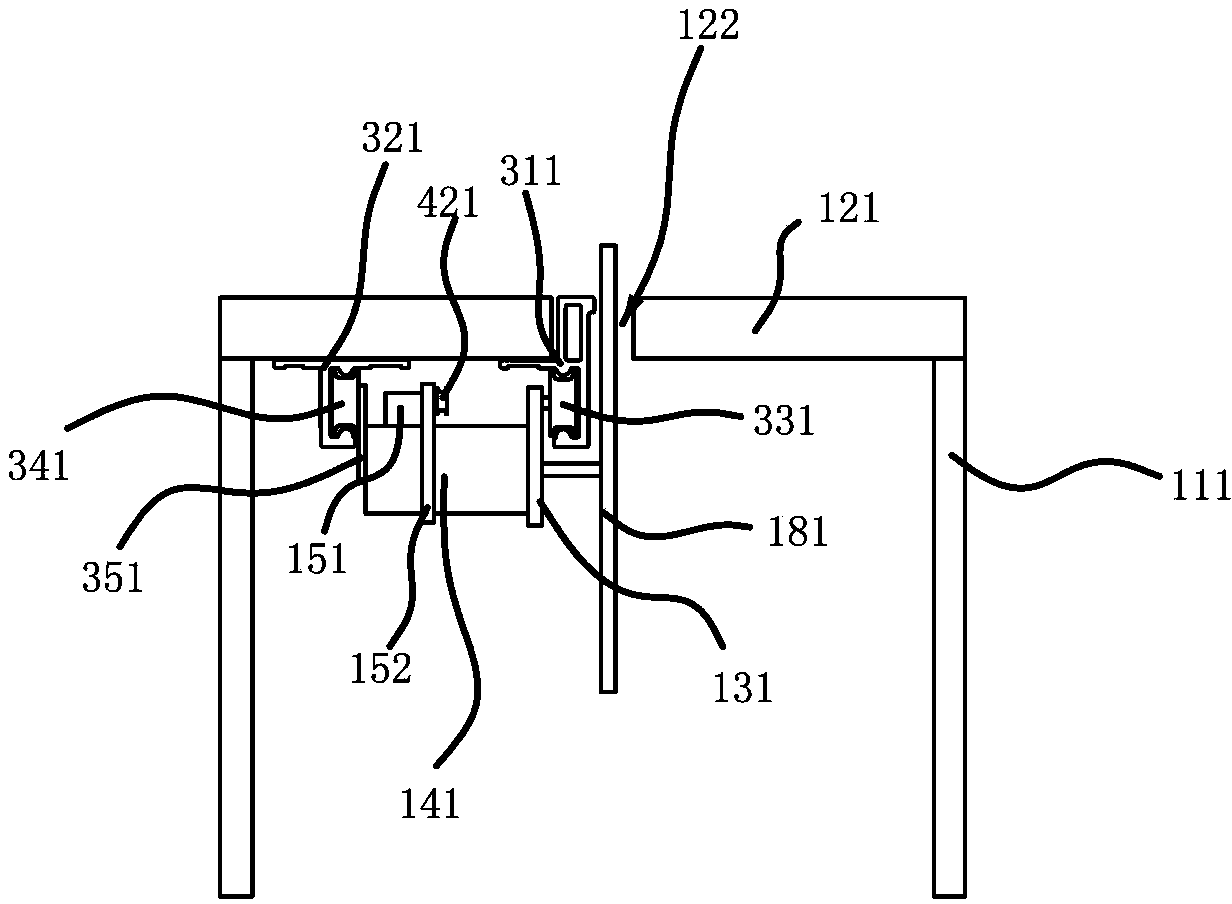

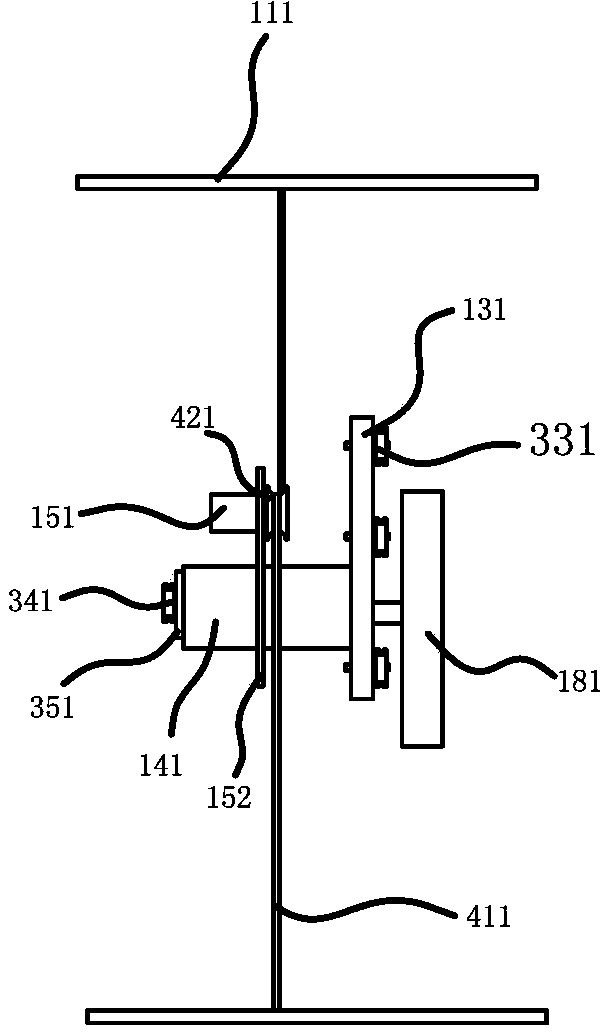

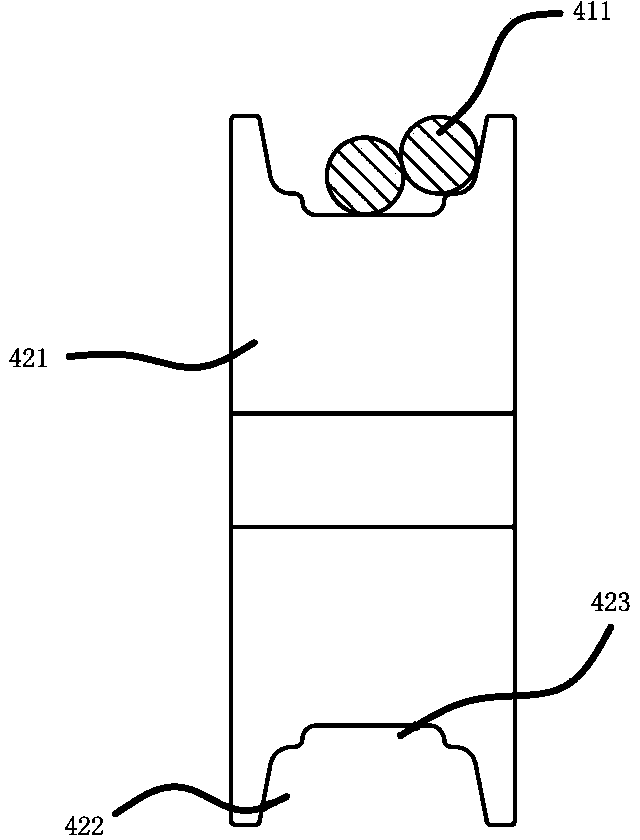

[0045] A sawing machine, the sawing machine includes a frame 111, a workbench 121 fixed on the frame 111 and an electric saw that can slide along the workbench 121, and the electric saw includes a handle for manually pushing the electric saw to move, such as figure 1 and figure 2 As shown, the saw machine also includes a guide rope 411 and a fixed rod 431. The guide rope 411 is arranged along the sliding direction of the chainsaw. The guide rope 411 includes a steel wire rope 412 and a rubber sheath 413 wrapping the steel wire rope 412. One end of the guide rope 411 is fixed on the frame 111 On one side, the other end of guide rope 411 is fixed on the fixed rod 431, and fixed rod 431 is positioned at the other side of frame 111, is provided with between fixed rod 431 and frame 111 and can adjust the fixed rod 431 and frame 111 one side. The distance between them makes the guide rope 411 tense or loosen the adjustment mechanism. A walking motor 151 that can drive the chainsaw ...

Embodiment 2

[0062] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the adjustment mechanism includes an adjustment hole and a nut provided on the frame. The rod passes through the nut and is threadedly connected with the nut, the end of the fixed rod positioned inside the frame is fixed with the guide rope, and the end of the fixed rod positioned outside the frame is the handle end. By turning the fixed rod at the handle end, the guide rope can be tensioned when the fixed rod moves out of the frame to a certain position. At this time, the walking motor is used to control the walking of the chainsaw. The rope is slack, and the movement of the chainsaw is manually controlled at this time.

Embodiment 3

[0064] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 19 and Figure 20 As shown, the handle is a wireless handle, and the wireless handle includes a handle 521 and a connecting plate 511, a wireless transmitter 533 is fixed on the handle 521, a wireless receiver is fixed on the mounting plate 131, the wireless receiver is connected to the controller, and the handle One end of 521 is fixed on the connection plate 511 , and the other end of the connection plate 511 is fixed with a protective cover 561 , and the protective cover 561 is located above the saw blade 181 . When the sawing machine is switched to manual mode, the handle 521 is used to push the chainsaw to move to realize manual cutting of wood; the wireless receiver is connected to the driving motor 141, and the wireless transmitter 533 on the handle 521 transmits a signal, so that the wireless receiver controls the driving motor 141 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com