Preparation technology of light guide concrete

A preparation process and concrete technology, which are applied in the field of preparation of building materials, can solve the problems of affecting economic benefits, low efficiency, confusion of procedures, etc., and achieve the effects of high economic benefits, high work efficiency, and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

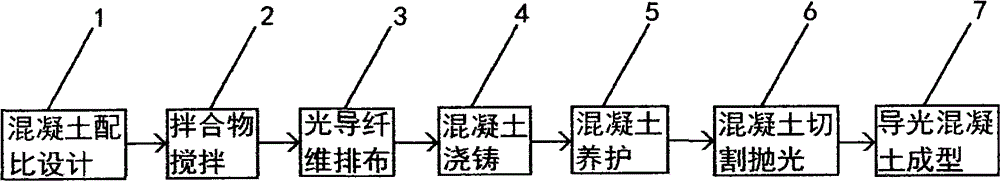

[0020] First, the concrete mix design 1 is carried out. The design follows the mix design specifications of ordinary concrete and lightweight aggregate concrete. According to the requirements of light conductivity, the particle size of coarse aggregate is selected, that is, if the light conductivity is high, the bone The particle size of the aggregate is small. The aggregate size is large if the light conductivity is low. The aggregate size is generally 5-25mm. The concrete mix ratio materials include cement, fly ash, ground slag powder and silica fume cementitious materials, coarse and fine bones. Materials, water, additives.

[0021] After the concrete is proportioned, mix the proportioned mixture 2 at a mixing temperature of -15°C-40°C. In order to ensure uniform mixing of the concrete, a forced mixer is selected and the mixing time is not less than 45 seconds.

[0022] After the mixing is completed, the optical fibers are arranged. The optical fibers are embedded in the concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com