Semi-aromatic and aliphatic polyamide block copolymer and preparation method thereof

A technology of aliphatic polyamide and block copolymer, which is applied in the field of semi-aromatic and aliphatic polyamide block copolymer and its preparation, can solve the problems of heavy pollution, low industrialization value and high cost, etc. To achieve the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A4

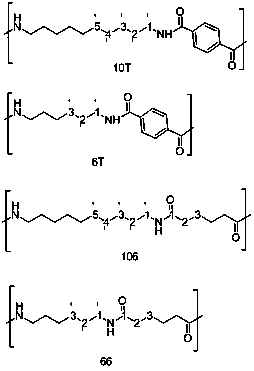

[0032] Examples A1-A4: Preparation of semi-aromatic polyamide prepolymer

[0033] In the autoclave equipped with magnetic coupling stirring, condensation pipe, gas phase port, feeding port, pressure explosion-proof port, add the reaction raw materials according to the ratio in Table 1; the amount of benzoic acid is the total amount of diamine, diacid, lactam and amino acid 2.5% of the amount of substance, the weight of sodium hypophosphite is 0.1% of the weight of other feeds except deionized water, and the weight of deionized water is 30% of the weight of the total feed; Heat up to 220 within hours o C, the reaction mixture was heated at 220 o C was stirred for 1 hour, and then the temperature of the reactant was raised to 230 o C; response at 230 o The constant temperature of C and the constant pressure of 2.2MPa continued for 2 hours, and the pressure was kept constant by removing the formed water. After the reaction was completed, the material was discharged, and the p...

Embodiment B5-B9

[0034] Examples B5-B9: Preparation of Aliphatic Polyamide Prepolymer

[0035]In the autoclave equipped with magnetic coupling stirring, condensation pipe, gas phase port, feeding port, pressure explosion-proof port, add the reaction raw materials according to the ratio in Table 1; the amount of benzoic acid is the total amount of diamine, diacid, lactam and amino acid 2.5% of the amount of substance, the weight of sodium hypophosphite is 0.1% of the weight of other feeds except deionized water, and the weight of deionized water is 30% of the weight of the total feed; Heat up to 200 within hours o C, the reaction mixture was heated at 200 o C was stirred for 1 hour, and then the temperature of the reactant was raised to 210°C with stirring o C; response at 210 o The constant temperature of C and the constant pressure of 2.2MPa continued for 2 hours, and the pressure was kept constant by removing the formed water. After the reaction was completed, the material was discharge...

Embodiment C10-C18

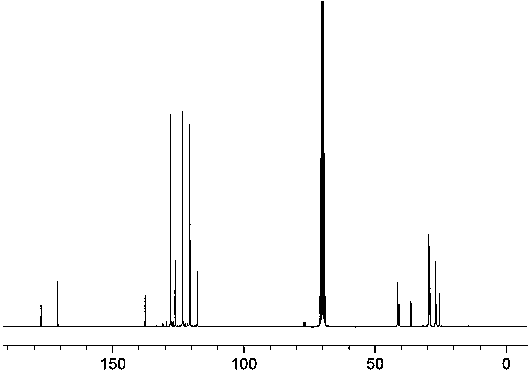

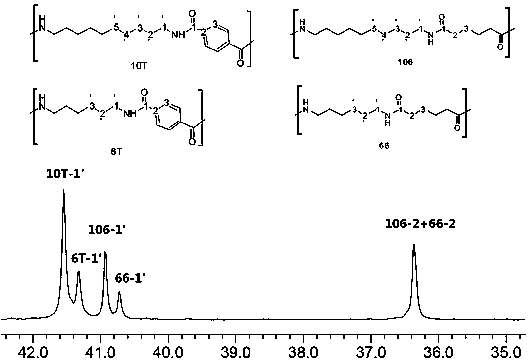

[0036] Examples C10-C18: Preparation of Semiaromatic and Aliphatic Polyamide Block Copolymers

[0037] Add the reaction raw materials according to the ratio in Table 2 in the autoclave equipped with magnetic coupling stirring, condenser, gas phase port, feeding port, and pressure explosion-proof port. The weight of deionized water is 30% of the total feeding weight; vacuumize and fill high-purity nitrogen as a protective gas, and heat up to 200 within 2 hours under stirring. o C, the reaction mixture was heated at 200 o C was stirred for 1 hour, and then the temperature of the reactant was raised to 210°C with stirring o C; response at 210 o The constant temperature of C and the constant pressure of 2.2MPa continued for 2 hours, and the pressure was kept constant by removing the formed water. After the reaction was completed, the material was discharged, and the prepolymer was at 80 o C under vacuum drying 24 hours, obtain prepolymerized product; Described prepolymerized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com