Organic material deposition system

A technology of organic materials and deposition systems, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as time increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

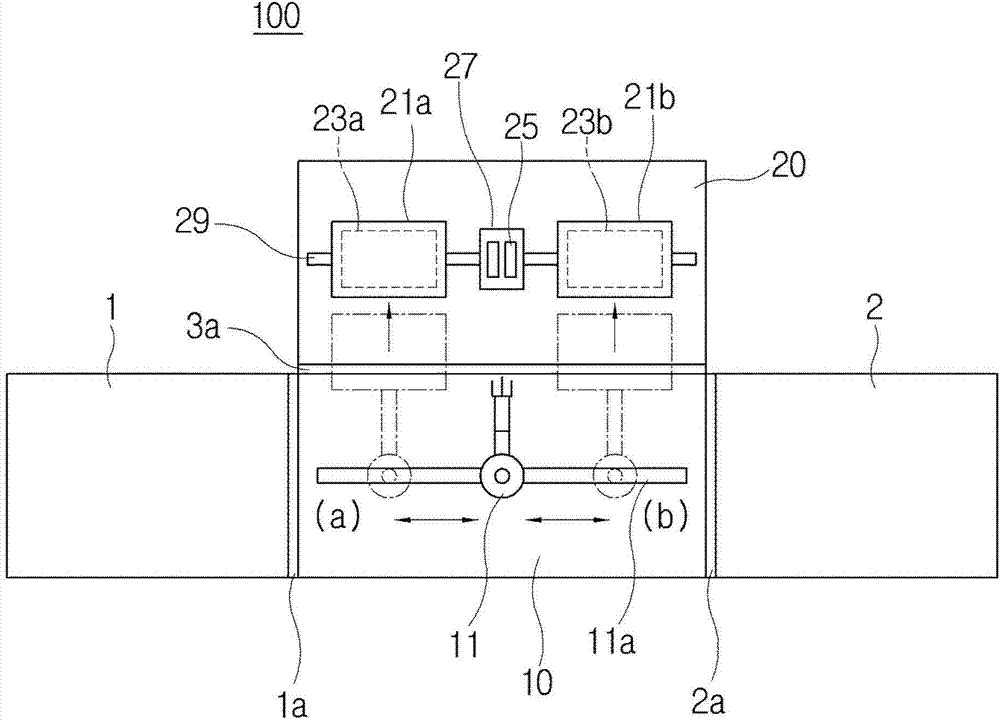

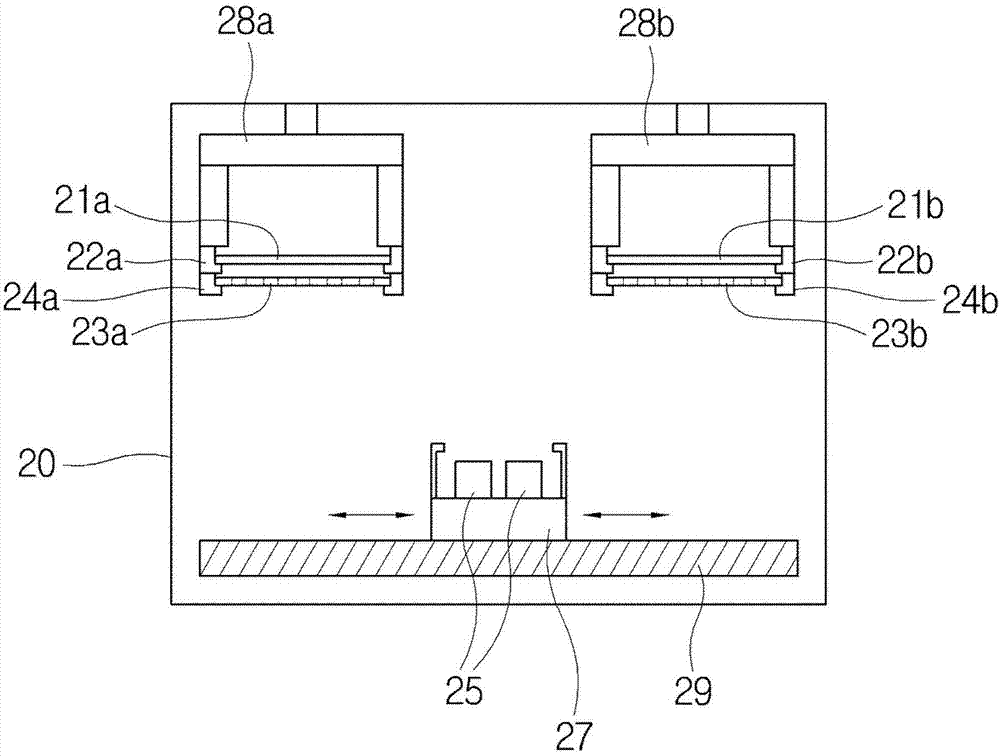

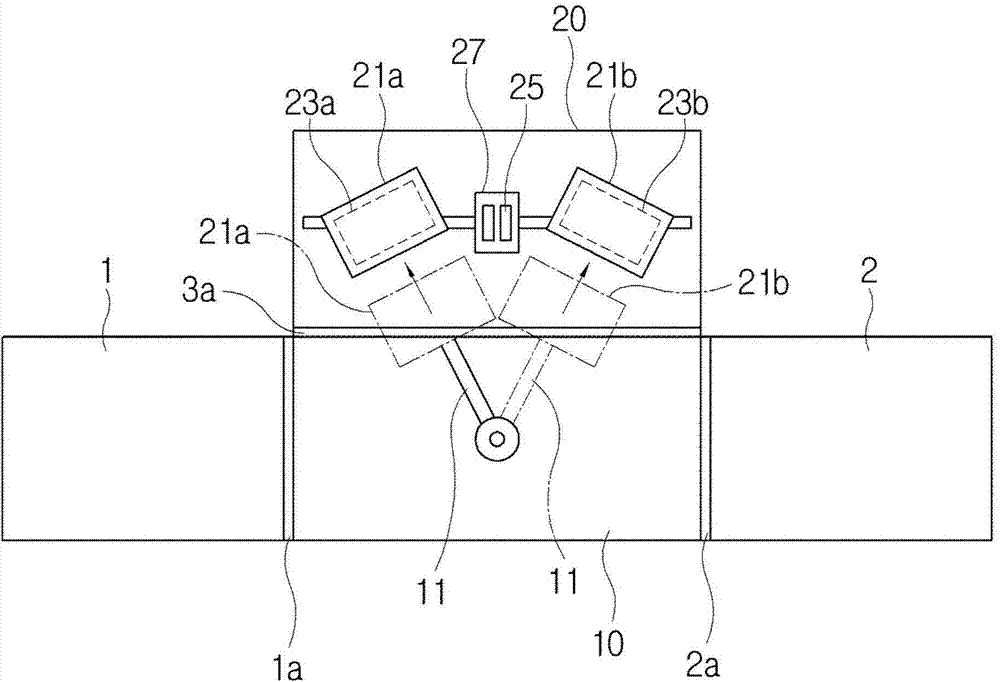

[0032] Hereinafter, exemplary embodiments of an organic material deposition system according to the present invention will be described in detail with reference to the accompanying drawings.

[0033] image 3 is a plan view of an organic material deposition system according to an embodiment of the present invention. Such as image 3 As shown, the organic material deposition system according to the embodiment of the present invention includes a process chamber 20 and a transport chamber 10, in which the process of depositing an organic material on a substrate is implemented in the process chamber 20, and in the transport chamber 10, the substrate is transported to process chamber 20. Of course, the transfer chamber 10 may be connected to a load / unload chamber or a load lock chamber as described in conventional organic material deposition systems.

[0034] As described in conventional organic material deposition systems, the process chamber 20 is provided with substrate holde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap