Plasma vapor deposition material two-sided locally-growing device and method

A growth device and plasma technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of complex operation and low efficiency, and achieve the effect of simple operation, improved work efficiency and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

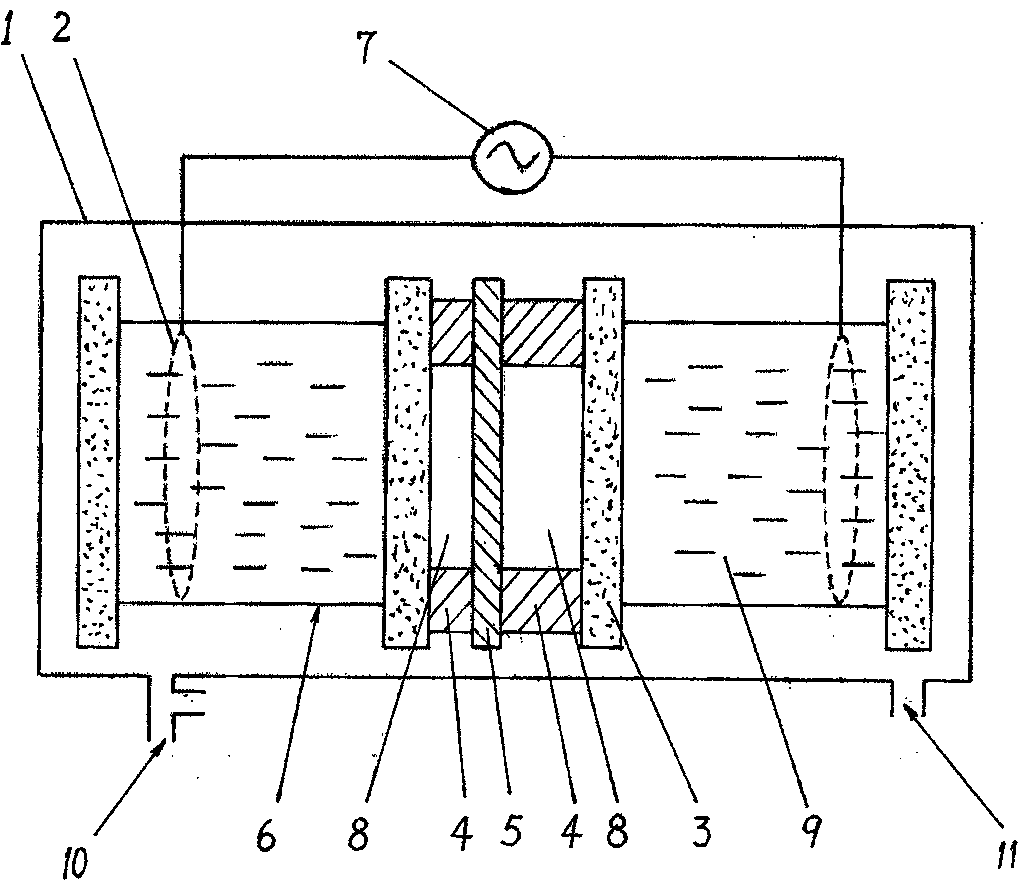

[0035] Embodiment 1: Device for localized growth of double-sided materials by plasma vapor deposition.

[0036] Such as figure 1 As shown, an air inlet 10 and an air extraction port 11 are opened on the wall of the vacuum reaction chamber 1, the air inlet 10 is a three-way nozzle, one nozzle is connected to the injection device of the discharge gas, and the other nozzle is connected to the chemical gas phase Injection device for gases required for deposition. Two water electrodes 6 are arranged in the vacuum reaction chamber 1 .

[0037] The form of the water electrode 6 is: a discharge medium plate 3 is sealed at both ends of the plexiglass tube 9 to form a cylindrical airtight dielectric container; a copper ring 2 is built in the dielectric container and is connected to the copper ring 2 After the lead wire passes through the dielectric container, it is connected to the positive or negative electrode of the plasma power supply 7 arranged outside the vacuum reaction chamber...

Embodiment 2

[0042] Embodiment 2: A method for localized growth of double-sided materials by plasma vapor deposition.

[0043] The method for local growth of double-sided materials in the present invention is carried out in the above-mentioned local growth device for double-sided materials, and specifically includes the following steps:

[0044] a. Inject discharge gas into the vacuum reaction chamber 1 through the air inlet 10 until the air pressure in the vacuum reaction chamber 1 reaches 0.3-1 atmospheric pressure;

[0045] b. Turn on the plasma power supply 7, control the discharge voltage to 4-7.8kV, and the discharge condition of the power supply frequency to 60kHz. A discharge is generated in the electric gap 8, and plasma patterns are formed on both sides of the material growth substrate 5;

[0046] c. After the plasma pattern is stabilized, the gas required for chemical vapor deposition is injected into the vacuum reaction chamber 1 through the gas inlet 10, and the gas is extrac...

Embodiment 3

[0048] Example 3: Local growth of double-sided materials with the same discharge air gap thickness on both sides.

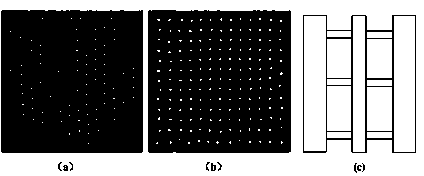

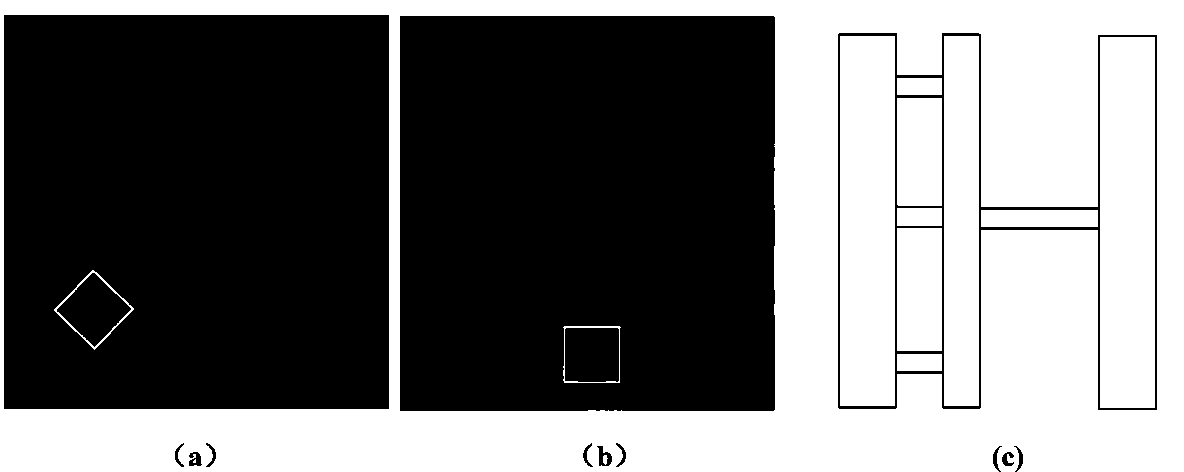

[0049] In the double-sided material local growth device of the present invention, the thickness of the material growth substrate 5 is 1 mm, and the two insulator frames 4 are square planar frames with an inner side length of 30 mm, and the thickness of the two insulator frames 4 (that is, two placed The thickness of the electric gap 8) is 1.5mm, the injected discharge gas is air, the pressure is 0.3 atmospheres, the power frequency of the plasma power supply 7 is 60kHz, and the peak value of the discharge voltage is 4.8kV. A hexagonal double layer plasma pattern can be produced, see figure 2 (a).

[0050] The argon content of the injected discharge gas is 93%, the air content is 7%, the air pressure is 1 atmosphere, and the discharge voltage is 7.8kV. Other conditions are the same as figure 2 When the conditions in (a) are the same, a quadrilateral double-lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com