Composite-structure porous shaft slip form construction device and method

A complex structure, sliding form technology, applied in vertical shaft equipment, wellbore lining, earthwork drilling, etc., can solve the problems of high construction cost, complex procedures, long construction period, etc., save materials, avoid repeated disassembly and assembly, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

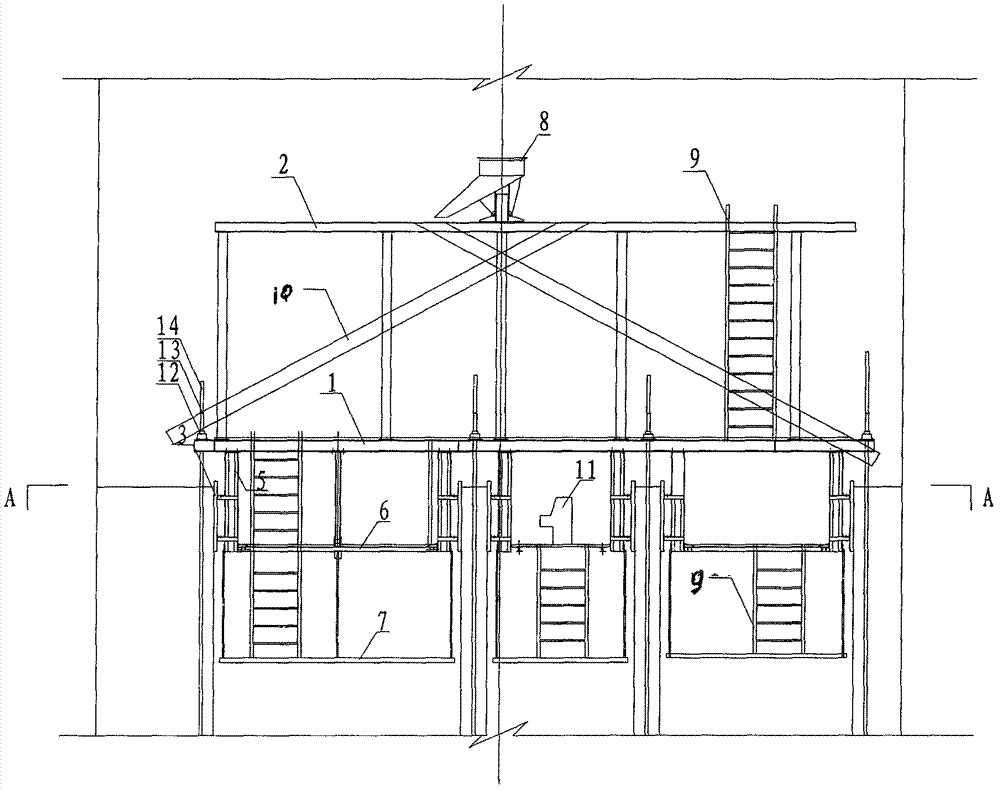

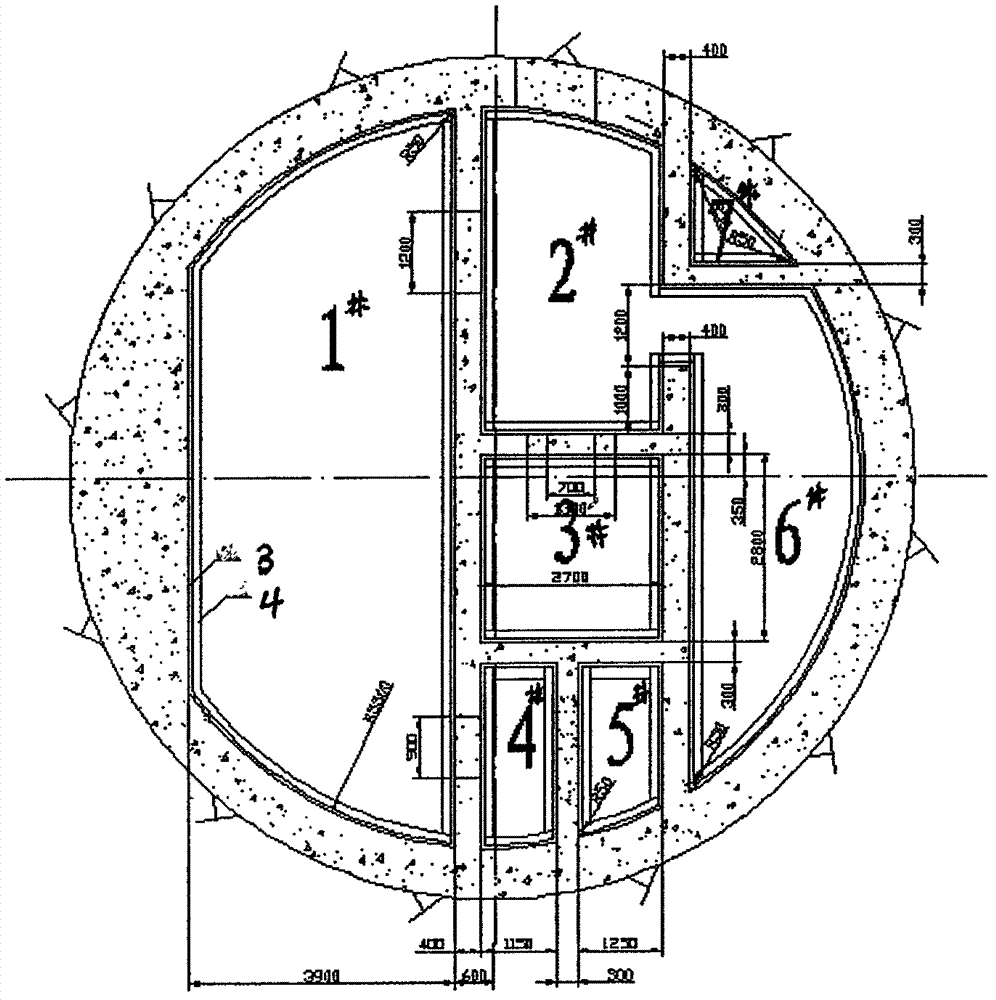

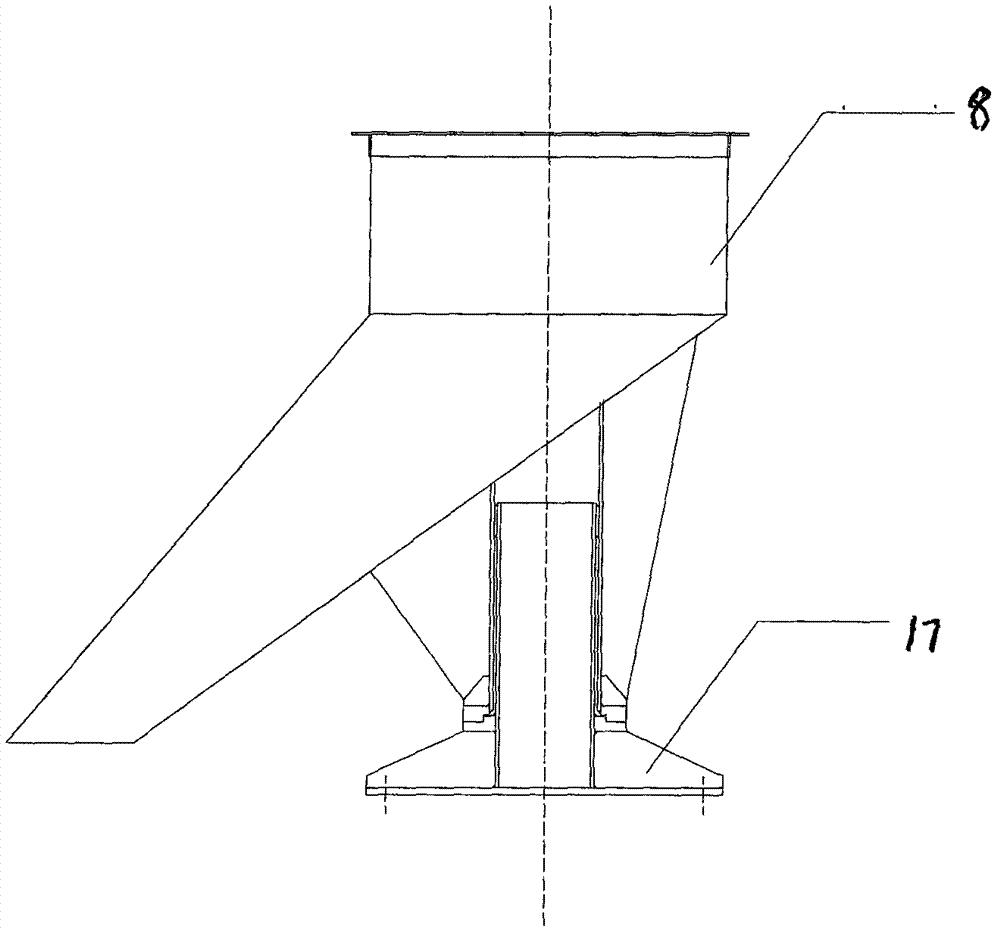

[0007]According to the actual situation of the multi-hole shaft with complex structure, the slip-form construction device for the multi-hole shaft with complex structure is designed and manufactured. The construction device consists of a sliding form system, a material distribution system, and a hydraulic system; the sliding form system consists of a formwork group (3), an enclosure (4), a lifting frame (5), a main platform (1), an auxiliary platform (6), stairs ( 9), climbing rods (14); the material distribution system is composed of a distribution platform (2), a rotating hopper (8), a fixed chute (10), and a plastering platform (7); the hydraulic system is composed of a hydraulic jack (12), a hydraulic pump Station (11), limit leveler (13); Its characteristics are: 1. Formwork group composition and size: the formwork is composed of panels and webs, and is made of steel plates with the grade Q235, and the panels are the parts that are in contact with concrete. During the pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com