Backlight module and liquid crystal display device

A liquid crystal display device and backlight module technology, which is applied to lighting devices, fixed lighting devices, optics, etc., can solve problems such as local dark areas, poor optical quality, uneven light mixing, etc., and achieve increased coverage and improved The effect of optical taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

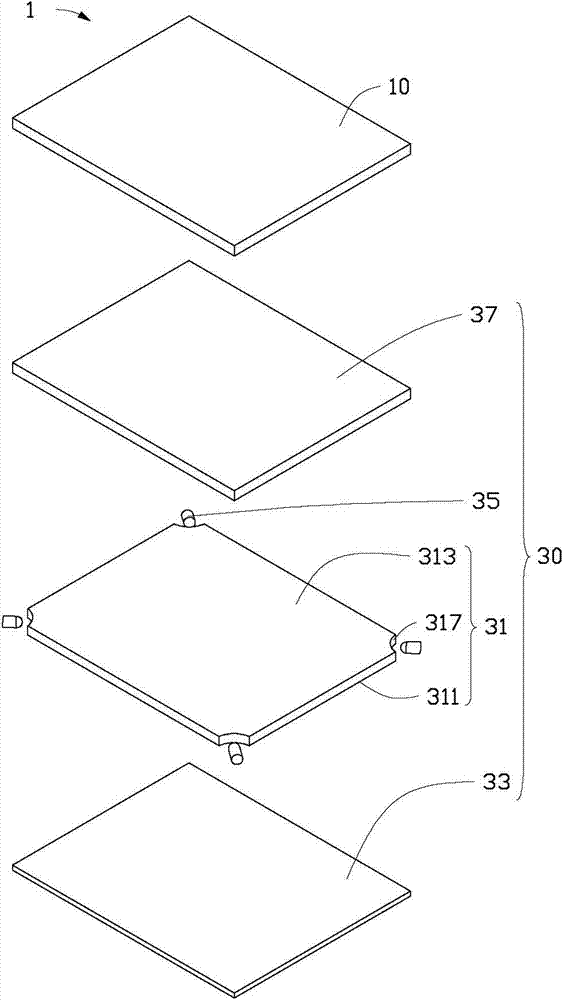

[0029] Please refer to figure 1 , is a three-dimensional exploded schematic diagram of a preferred embodiment of the liquid crystal display device of the present invention. The liquid crystal display device 1 includes a liquid crystal display panel 10 and a backlight module 30 opposite to the liquid crystal display panel. The backlight module 30 provides planar light for the liquid crystal display panel 10 .

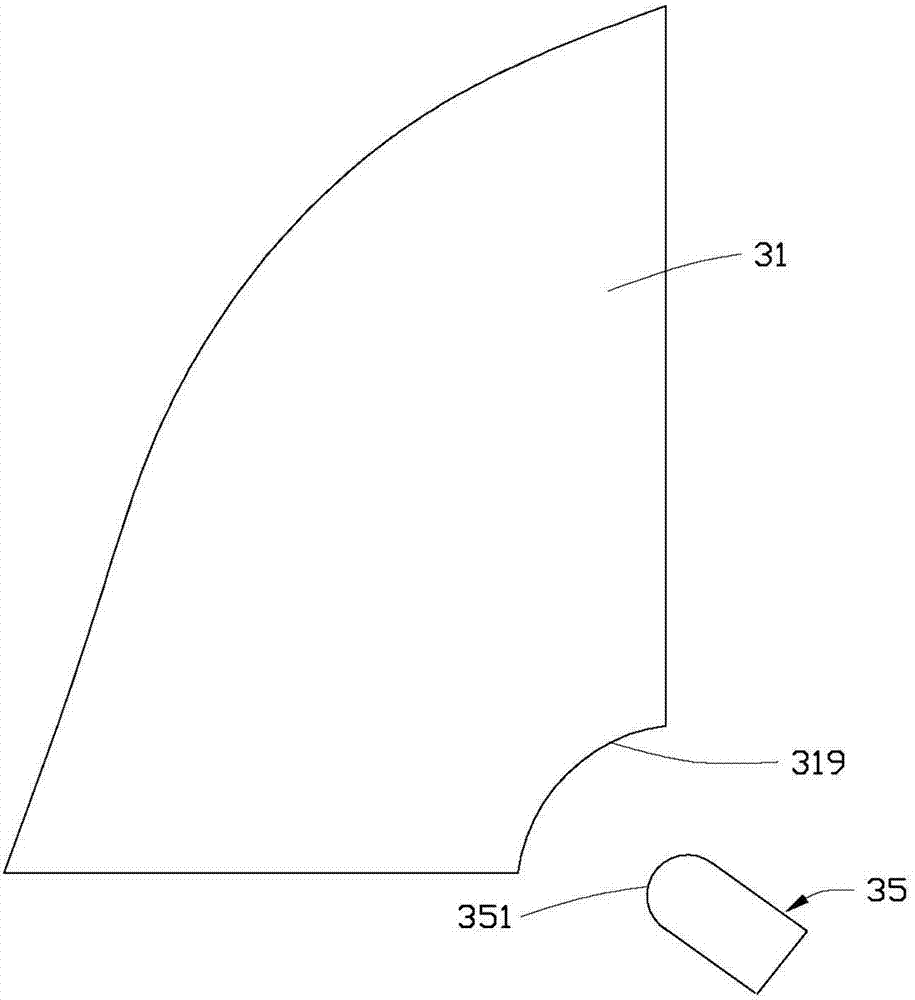

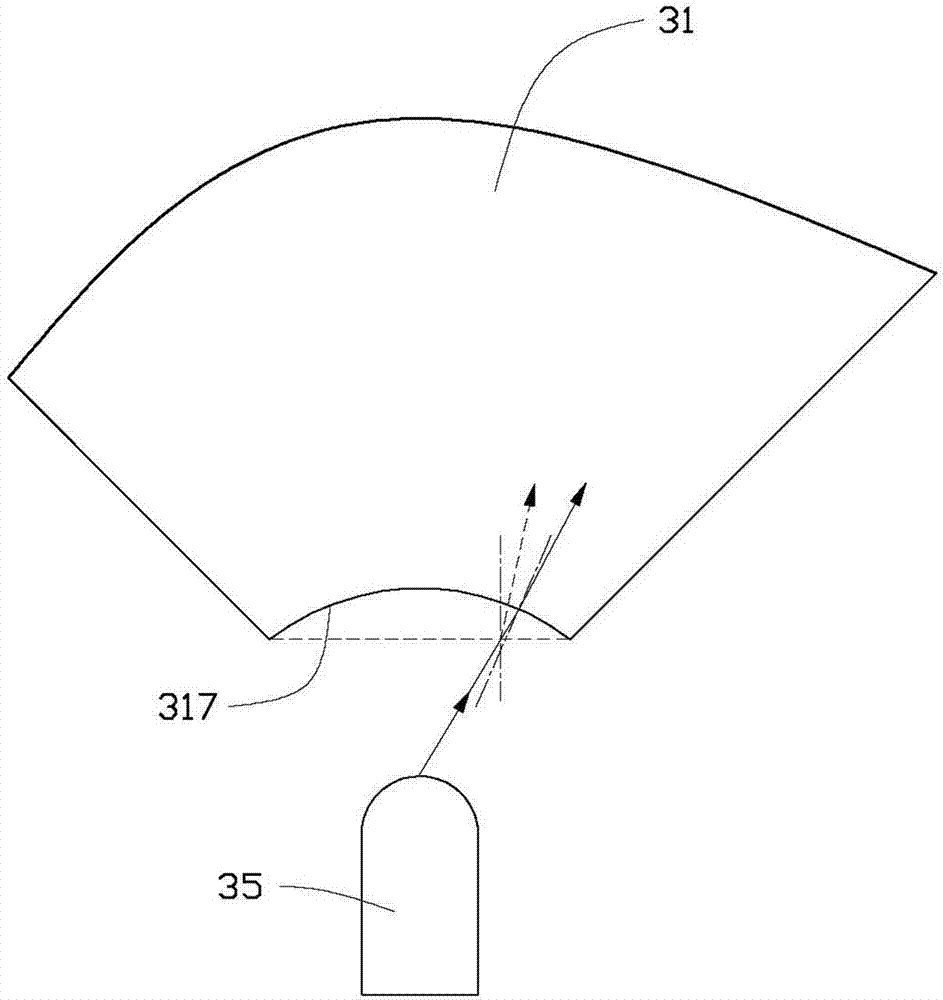

[0030] The backlight module 30 includes a light guide plate 31 , a reflection sheet 33 , at least one point light source 35 and at least one optical film 37 . In this embodiment, the light guide plate 31 is a flat light guide plate, and at least one corner of the light guide plate 31 is cut off, so as to form a corresponding cut surface 317 on the light guide plate 31 . The cut surface 317 has at least one bending unit 319, one point light source 35 is provided corresponding to one bending unit 319, and the cut surface 317 is used as the light incident surface of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com