Performance detection device of heat-resisting PET (Polyethylene Terephthalate) bottle

A detection device, heat-resistant technology, applied in the direction of measurement device, material thermal analysis, and the use of stable tension/pressure to test material strength, etc. Accurate and reliable data, saving production and development costs, and reducing the effect of repeated testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

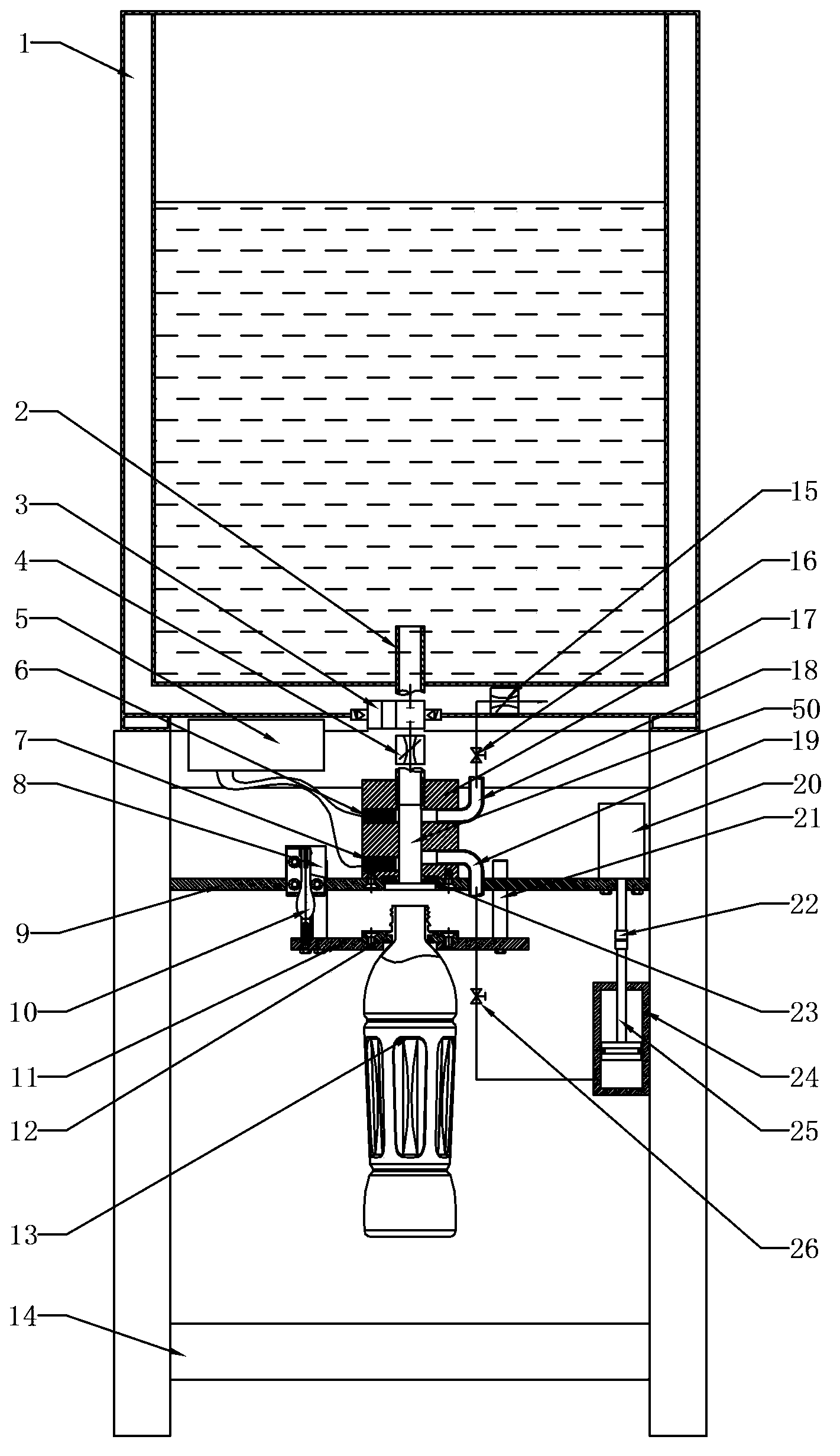

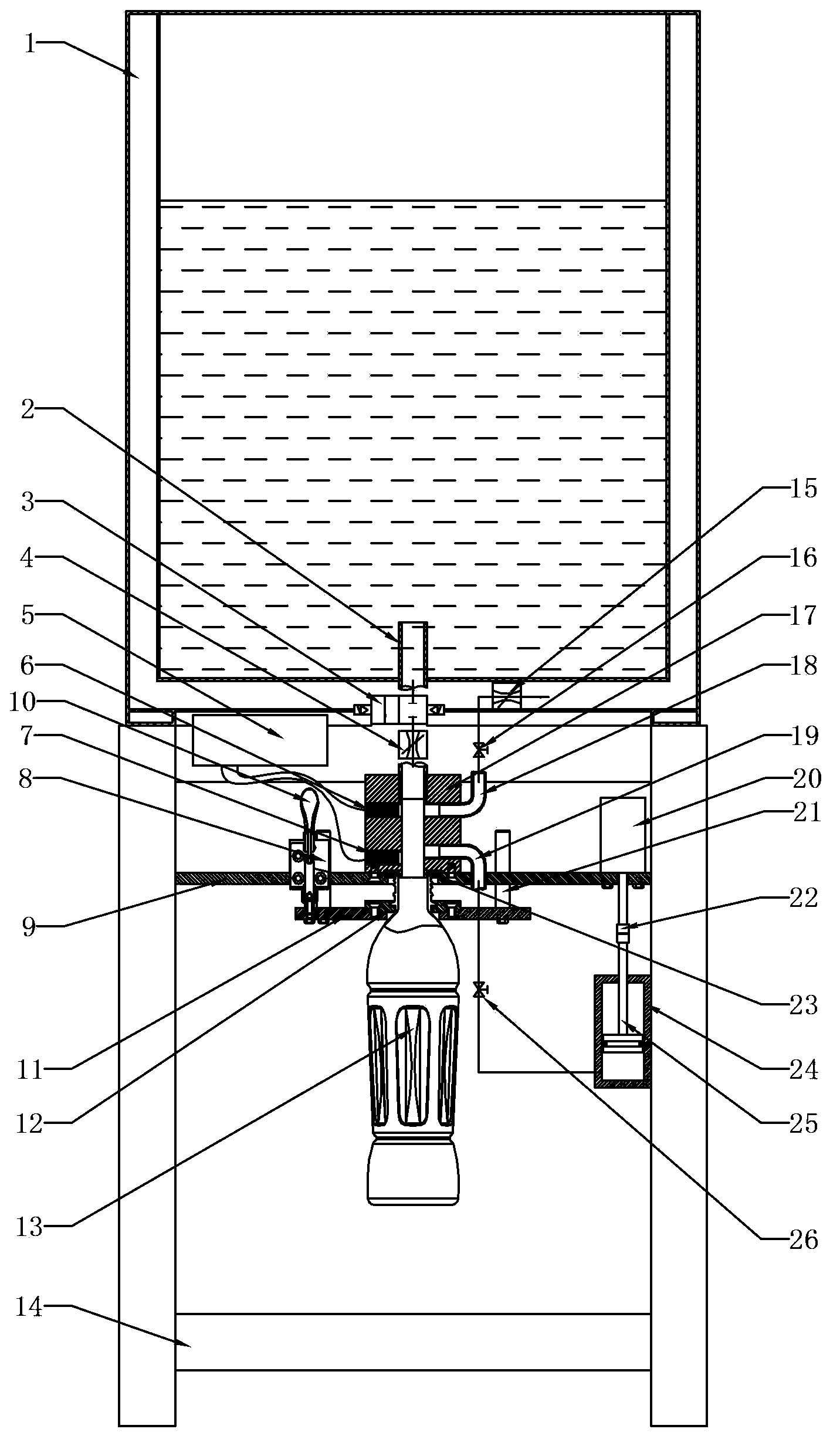

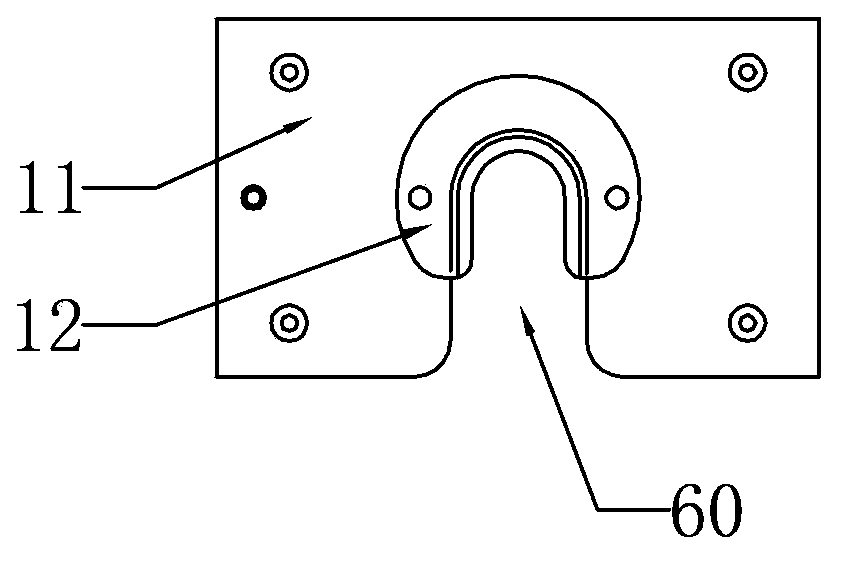

[0031] Such as Figure 1-7 As shown, it is a heat-resistant PET bottle performance detection device of the present invention, which includes a three-dimensional frame-shaped mounting frame 14, a lifting device located on the mounting frame 14, a hot filling pipe for accessing constant temperature hot water, and an installation Filling throttling device and filling valve, vacuum device, exhaust pipe 18 on the hot filling pipe, exhaust throttling device and exhaust valve installed on the exhaust pipe 18, mounting plate 9, connecting seat 17 and the electric control device, the filling throttling device and the exhaust throttling device adopt throttling valves 4 and 15, the water outlet of the hot filling pipe is vertically downward, and the lifting device is positioned at the bottom of the hot filling pipe so that it can be installed on The mouth of the heat-resistant PET bottle 13 on the lifting device is facing the water outlet of the hot-filling pipe, and the exhaust pipe 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com