Supercritical water cooled reactor fuel assembly and reactor core

A technology of fuel assembly and water-cooled reactor, which is applied to fuel elements, greenhouse gas reduction, nuclear power generation, etc. It can solve the problems of difficult manufacturing, high manufacturing cost, and large radial size, and achieve the solution of increased flow-induced vibration and reduced manufacturing Difficulty and manufacturing size, effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

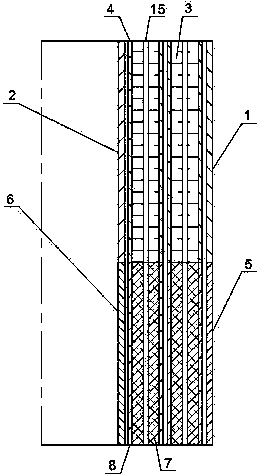

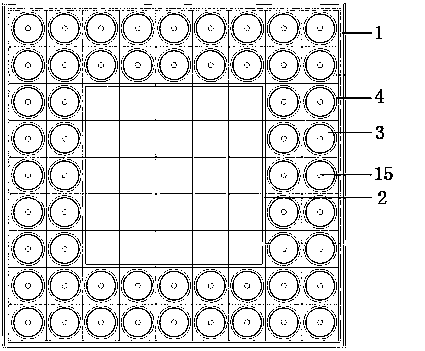

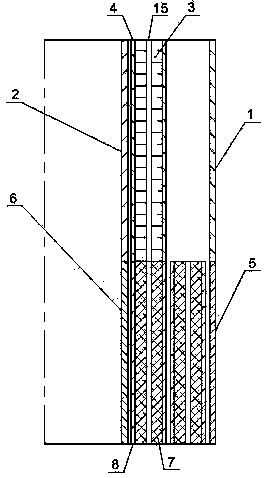

[0039] Such as figure 1 and figure 2 As shown, a supercritical water-cooled reactor fuel assembly includes a shell assembly and a core body arranged in the shell assembly, and an air cavity 15 is arranged in the middle of the core body. The fuel assembly is divided into upper and lower parts. The upper shell assembly includes an upper assembly box 1 , an upper moderator box 2 and an upper casing 4 . The upper moderator box 2 is arranged inside the upper assembly box 1 , and the upper core 3 is wrapped by the upper cladding 4 and evenly arranged between the upper moderator box 2 and the upper assembly box 1 . The lower housing assembly includes a lower assembly box 5 , a lower moderator box 6 and a lower cladding 8 . The lower moderator box 6 is arranged inside the lower component box 5 , and the lower core 7 is wrapped by the lower cladding 8 and evenly arranged between the lower moderator box 6 and the lower component box 5 . The upper shell assembly is made of nickel-ba...

Embodiment 2

[0047] Such as figure 1 As shown, this embodiment is based on Embodiment 1, the upper shell assembly is made of Inconel718 alloy, and the upper core 3 235 U enrichment degree is 6.2%, the lower core body 7 235 U enrichment is 2.5%. When the existing fuel assembly is made of Inconel718 alloy, the core body 235 The U enrichment is usually 6.2% to obtain the infinite proliferation factor (Kinf) required by the supercritical water-cooled reactor (the infinite proliferation factor characterizes the ratio of neutron production rate to neutron disappearance rate in an infinite system). In order to obtain the same infinite growth factor as the existing fuel assembly in this embodiment, the lower core 7 235 U enrichment was set at 2.5%. Due to the unfavorable neutron absorption of zirconium alloy, 2.5% 235 The U enrichment degree can be achieved with 6.2% when using Inconel718 alloy 235 U immortalization factor with the same enrichment.

[0048] The characteristics of this embod...

Embodiment 3

[0050] Such as figure 1 As shown, this embodiment is based on Embodiment 1, the upper shell assembly is made of 310S steel, and the upper core 3 235 U enrichment degree is 5.6%, the lower core body 7 235 U enrichment is 2.5%. When the existing fuel assembly is made of 310S steel, the core body 235 U enrichment is usually 5.6%, in order to obtain the unlimited proliferation factor required by supercritical water-cooled reactors. In order to obtain the same infinite growth factor as the existing fuel assembly in this embodiment, the lower core 7 235 U enrichment was set at 2.5%. Due to the unfavorable neutron absorption of zirconium alloy, 2.5% 235 U enrichment can be achieved and 5.6% when using 310S steel 235 U immortalization factor with the same enrichment.

[0051] The characteristics of this embodiment are: in reducing 235 In the case of U loading, a supercritical water-cooled reactor fuel assembly having the same geometrical dimensions and heating efficiency as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com