Nuclear reactor fuel cladding nano-composite coating and preparation method thereof

A nuclear reactor fuel, cladding nanotechnology, applied in the direction of reactor fuel elements, reactors, metal material coating processes, etc., can solve the problem of reducing the neutron economy of the cladding, fretting wear, and poor resistance to high temperature water vapor corrosion of zirconium alloys. and other problems to achieve the effect of reducing neutron economic loss, refining grains, and improving neutron economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

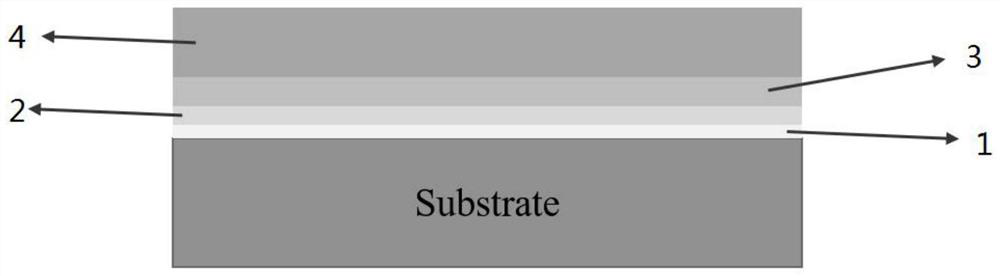

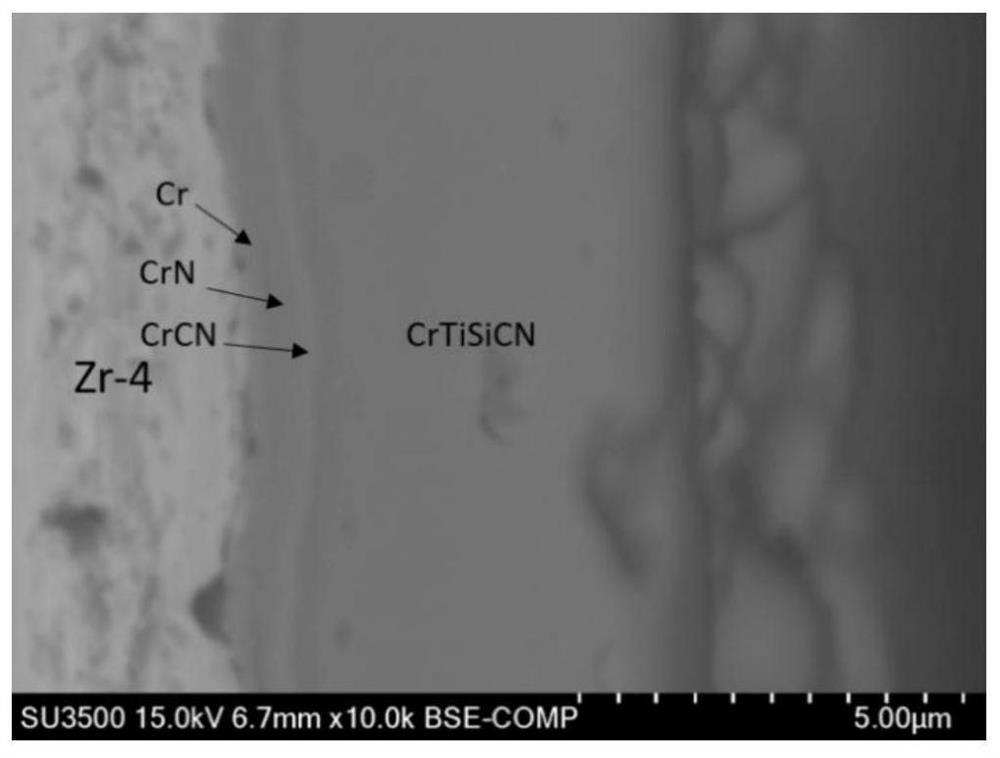

[0063] A nanocomposite coating for nuclear reactor fuel cladding, see figure 2 As shown, it includes: a metal layer 1, a first transition layer 2, a second transition layer 3 and a functional layer 4 that are sequentially stacked on the surface of the nuclear fuel cladding;

[0064] The composition of the metal layer 1 is Cr;

[0065] The composition of the first transition layer 2 is CrN, wherein the Cr content in CrN is 64.8 at%, and the N content is 35.2 at%);

[0066] The composition of the second transition layer 3 is CrCN, wherein the Cr content in CrCN is 58 at%, the C content is 16.2 at%, and the N content is 25.8 at%;

[0067] The composition of the functional layer 4 is CrTiSiCN, wherein the Cr content in CrTiSiCN is 27.4 at%, the Ti content is 33.0 at%, the Si content is 5.0 at%, the C content is 22.2 at%, and the N content is 12.4 at%.

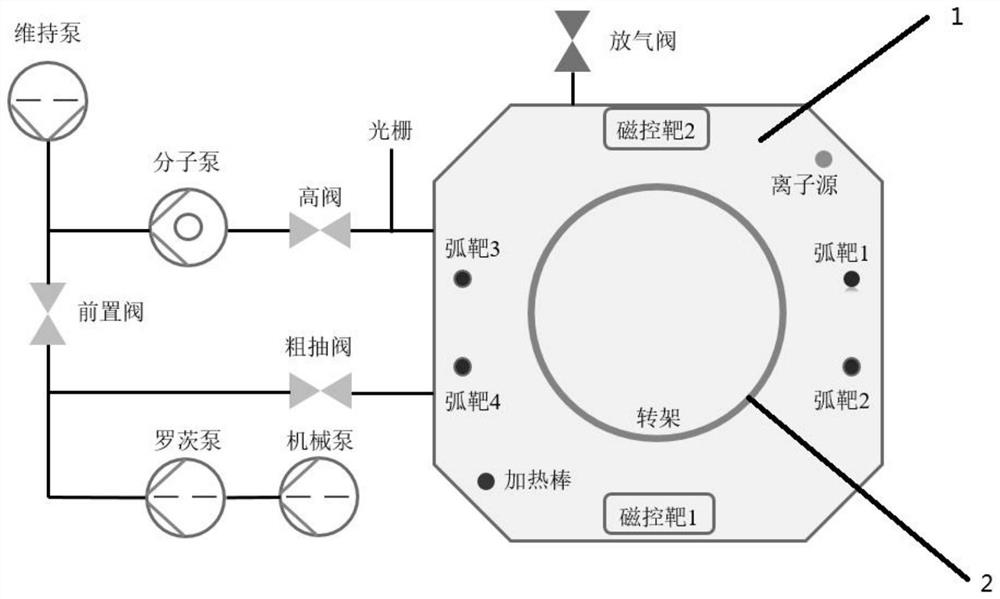

[0068] The above-mentioned nuclear reactor fuel cladding nanocomposite coating is prepared according to the following steps: ...

Embodiment 2

[0079] A nanocomposite coating for nuclear reactor fuel cladding, see figure 2 As shown, it includes: a metal layer 1, a first transition layer 2, a second transition layer 3 and a functional layer 4 that are sequentially stacked on the surface of the nuclear fuel cladding;

[0080] The composition of the metal layer 1 is Cr;

[0081] The composition of the first transition layer 2 is CrN, wherein the Cr content in CrN is 64.8 at%, and the N content is 35.2 at%);

[0082] The composition of the second transition layer 3 is CrCN, wherein the Cr content in CrCN is 58 at%, the C content is 16.2 at%, and the N content is 25.8 at%;

[0083] The composition of the functional layer 4 is CrTiSiCN, wherein the Cr content in CrTiSiCN is 33.6 at%, the Ti content is 45.3 at%, the Si content is 2.7 at%, the C content is 9.8 at%, and the N content is 8.6 at%.

[0084] The above-mentioned nuclear reactor fuel cladding nanocomposite coating is prepared according to the following steps:

[0...

Embodiment 3

[0092] It is the same as the embodiment 1, except that the cladding base material selected in this embodiment is a cylindrical zirconium alloy rod with a height of 15 mm and a diameter of 10 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com