Coating for improving corrosion resistance of zirconium alloy cladding tube by doping stabilized zirconium oxide

A technology for stabilizing zirconia and cladding tubes, used in coatings, anti-corrosion coatings, etc., can solve the problems of loss of protective effect of the oxide layer, cracking of the oxide layer, loss of protection, etc., and achieve excellent resistance to LOCA accidents and extended retention strength. time, the effect of reducing hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

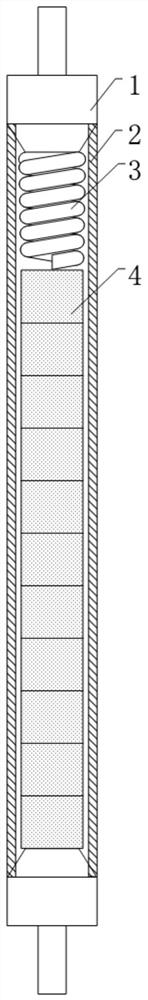

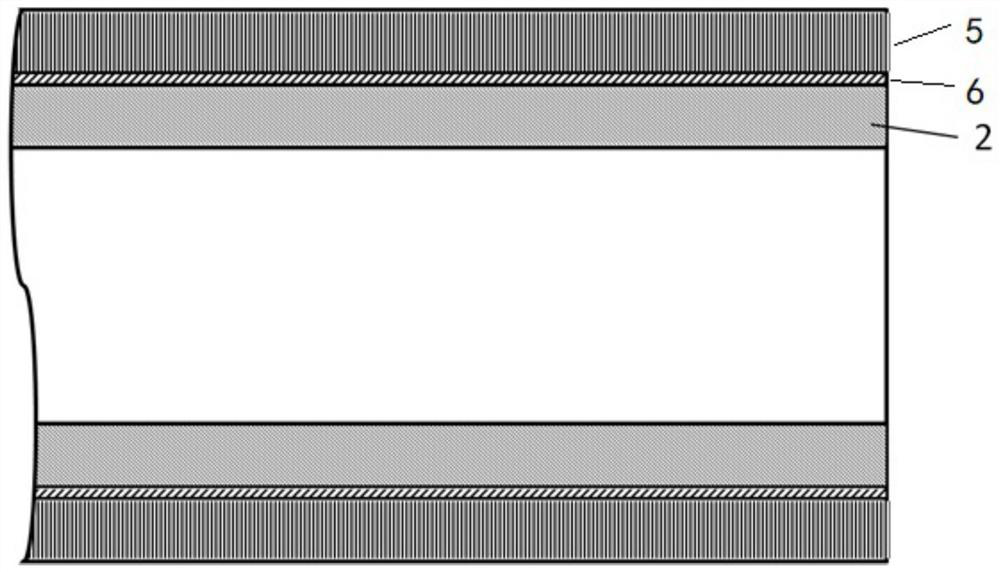

[0020] see figure 2 In this example, the surface of the zirconium alloy cladding 2 is coated with tetragonal doped stabilized zirconia formed by pure Cr as the transition layer 6 and zirconia doped with 5% yttrium oxide as the working layer 5 .

[0021] The characteristics of this example are: 1. Cr is used as the transition layer 6, which prevents the diffusion of oxygen in the working layer to the zirconium alloy matrix under high temperature conditions; 2. The zirconia doped with 5% yttrium oxide is stable in the tetragonal phase Phase; 3. Doped stabilized zirconia is used as the working layer 5, and the working layer does not undergo phase change at a room temperature above 25°C, which effectively prevents water vapor from eroding the zirconium alloy cladding 2; 4. The Cr transition layer is only 1-2 μm , the fuel assembly neutron economy loss is very low.

[0022] Therefore, the coating composed of the transition layer 6 and the working layer 5 in this example significa...

Embodiment 2

[0024] In this example, CrN is coated on the surface of the zirconium alloy cladding 2 as a transition layer 6, and cubic phase doped stabilized zirconia formed by doping 10% yttrium oxide in zirconia is used as a working layer.

[0025] The characteristics of this example are: 1. CrN is used as the transition layer 6, which prevents the oxygen element in the working layer 5 from diffusing to the zirconium alloy matrix under high temperature conditions; 2. The zirconia doped with 10% yttrium oxide has a cubic phase Stable phase; 3. Doped stabilized zirconia is used as the working layer 5, and the working layer does not undergo phase change at a room temperature above 25°C, which effectively prevents water vapor from eroding the zirconium alloy cladding 2; 4. The CrN transition layer 6 is only 1 ~2μm, the fuel assembly neutron economy loss is very low.

[0026] Therefore, the coating composed of the transition layer 6 and the working layer 5 in this example significantly improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com