A battery system

A battery system and battery cell technology, which is used in the repair/maintenance of secondary batteries, electric vehicles, vehicle energy storage, etc. Efficiency, extended service life, lower temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

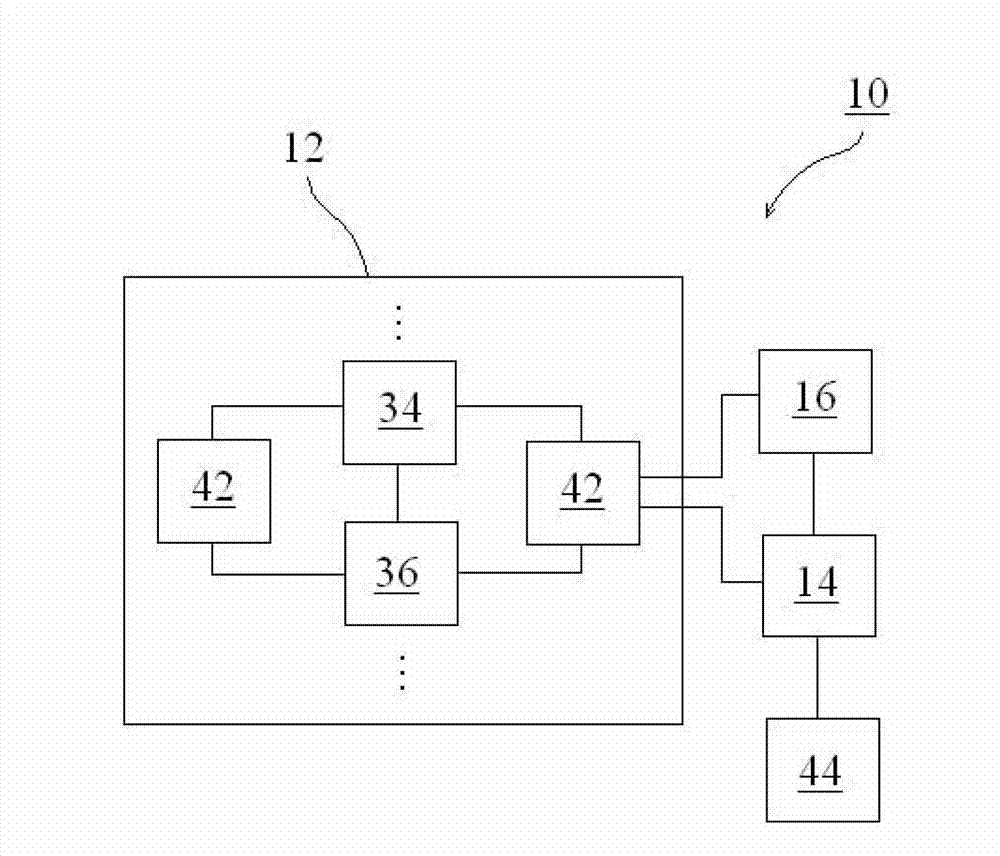

[0025] Please refer to the figures, the battery system 10 of a preferred embodiment of the present invention can be used as a power supply source for electric vehicles, including at least one battery module 12 and a control unit whose number can increase depending on the operating requirements of the electric vehicle 14.

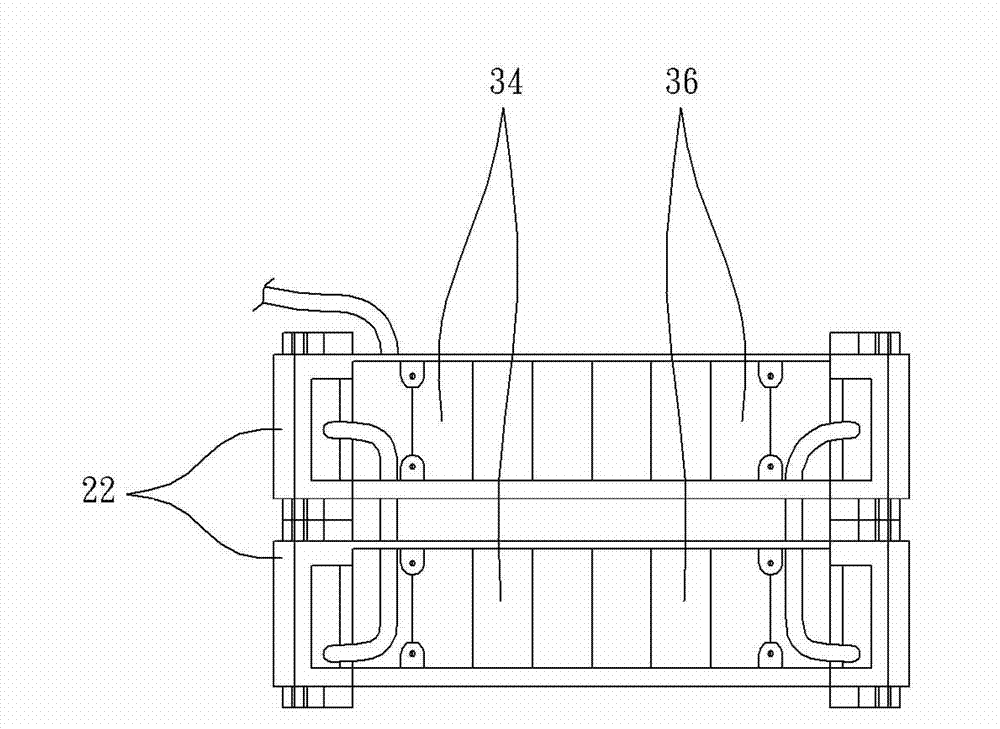

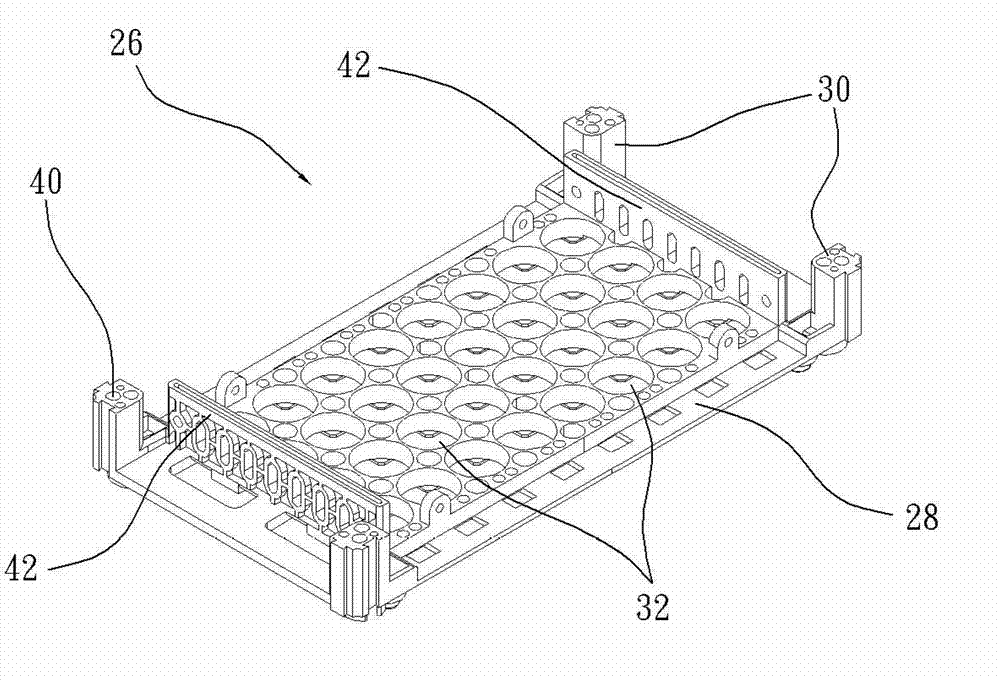

[0026] The battery module 12 includes a frame 22. The frame 22 is composed of an upper frame 24 and a lower frame 26. The upper and lower frames 24, 26 respectively include a rectangular carrier plate 28 and four sides of the carrier plate 28. The four connecting columns 30 at the corners, the carrier plates 28 of the upper and lower frames 24, 26 are respectively provided with the receiving grooves 32, which are used to accommodate a plurality of first bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com