Preceding-stage EMI filtering protective circuit of driving power source

A technology for driving power supply and protection circuit, applied in electrical components, output power conversion devices, etc., can solve the problems of insufficient electromagnetic interference filtering effect, insufficient insertion loss value, and failure of driving power supply, etc., to achieve high insertion loss, reliable Protection function, effect of reducing current stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

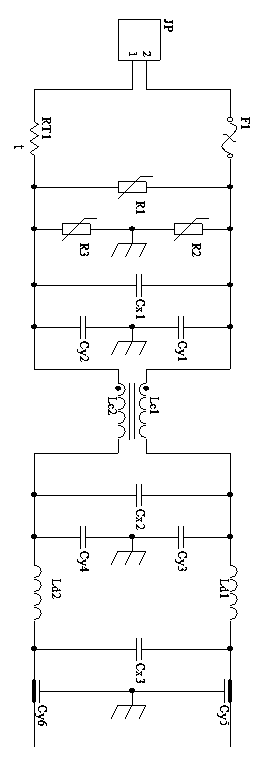

[0011] like figure 1 As shown, an EMI filter protection circuit at the front stage of the driving power supply includes a temperature-sensitive resistor RT1 for soft-starting and over-current protection of the driving power supply. One end of the first piezoresistor R1 is connected to the input of the AC power grid through the fuse F1 The live wire end, the other end of the first varistor R1 is connected to the neutral end of the AC grid input through the temperature sensitive resistor RT1, and the common end of the first varistor R1 and the fuse F1 is connected to the The ground, the common terminal of the first piezoresistor R1 and the temperature-sensitive resistor RT1 is connected to the ground through the third piezoresistor R3, the first differential mode capacitor Cx1 is connected in parallel with the first piezoresistor R1, the first common mode capacitor Cy1 is connected to the second Two varistors R2 are connected in parallel, the second common mode capacitor Cy2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com