Anti-icing vidicon

A camera and anti-icing technology, which is applied in the field of cameras, can solve the problems of difficult to remove the lens or transparent protective cover, low temperature resistance, easy freezing of the camera, etc., to achieve easy deicing treatment, prevent icing, and reduce the eradication area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

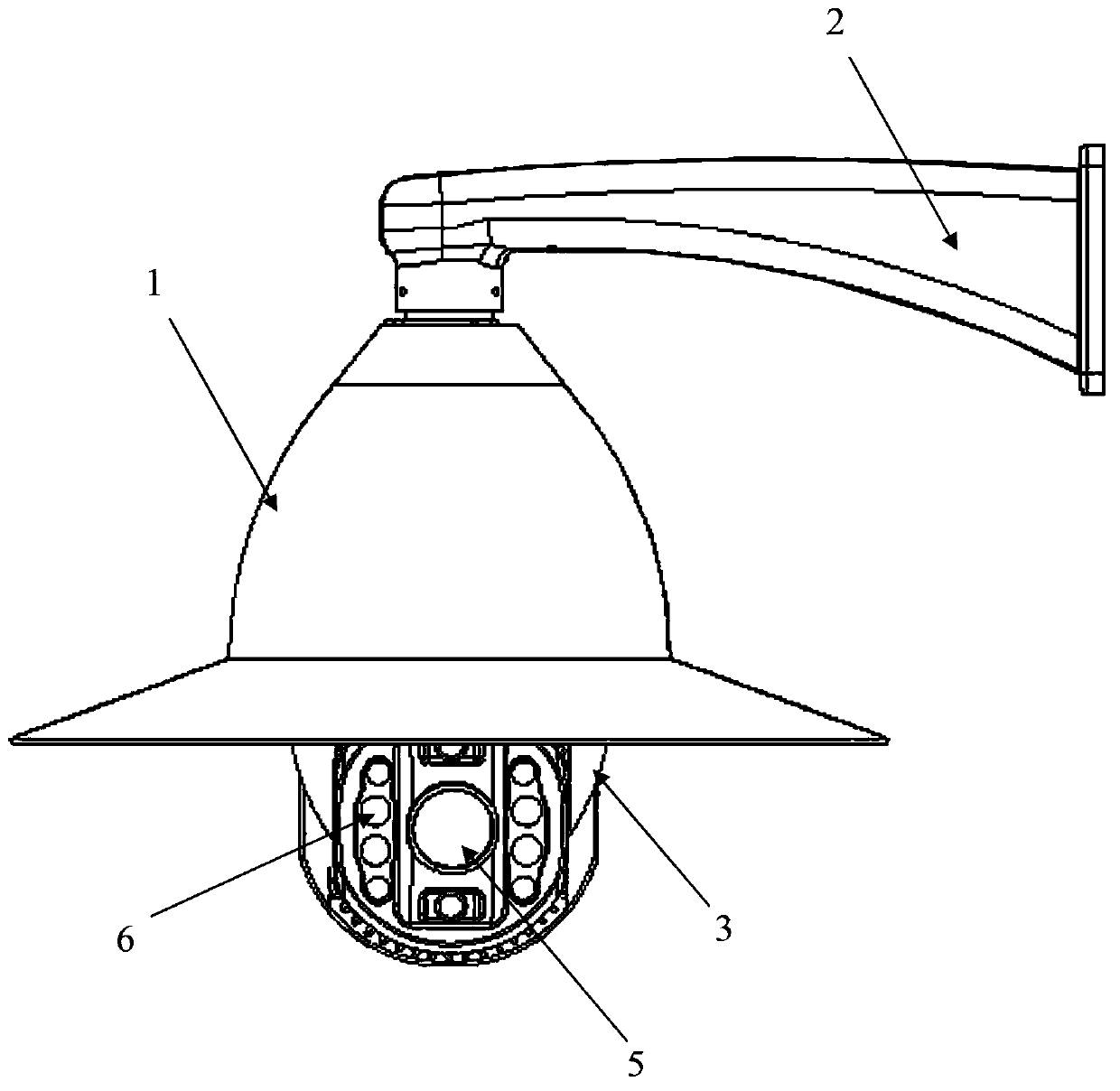

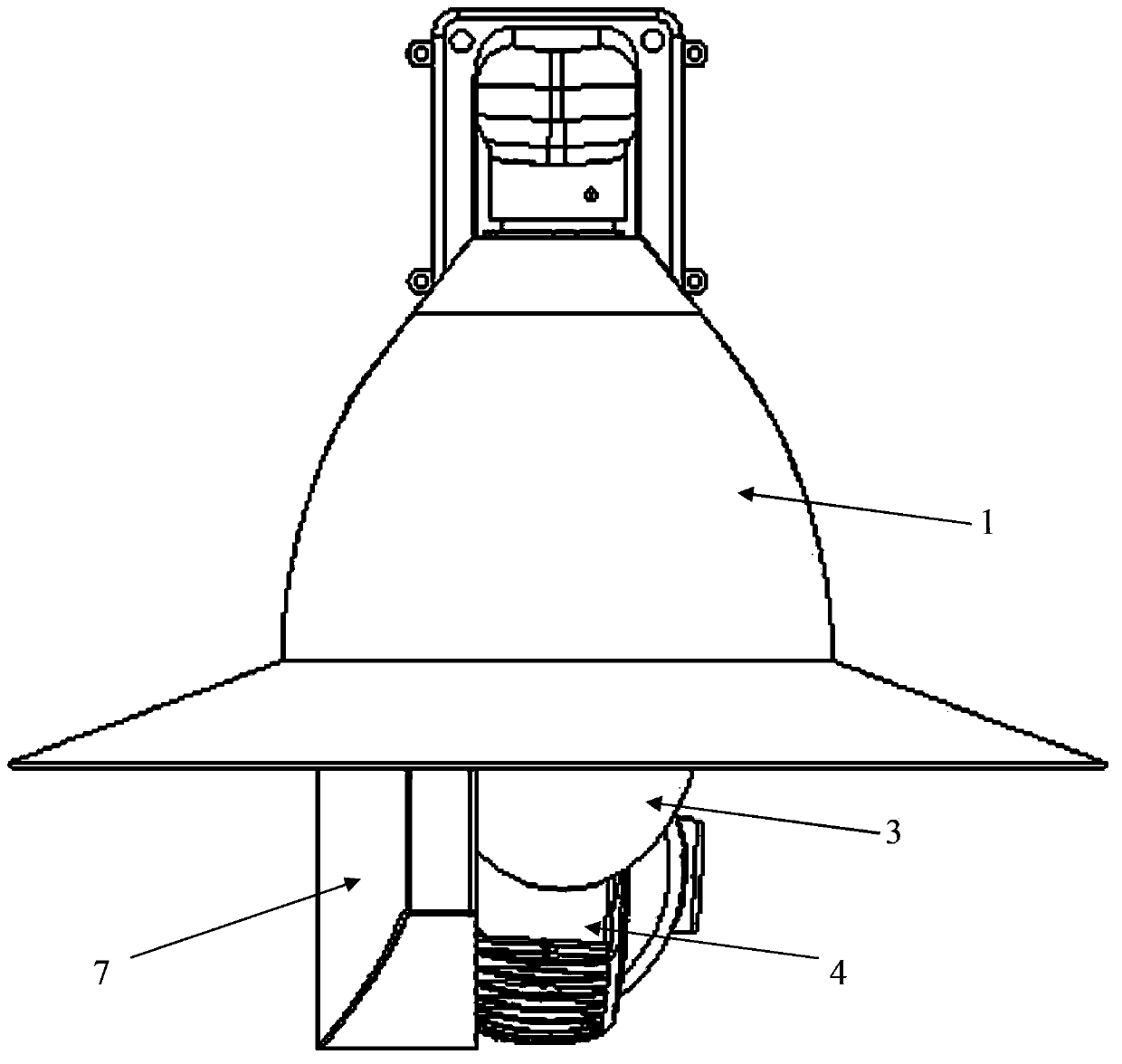

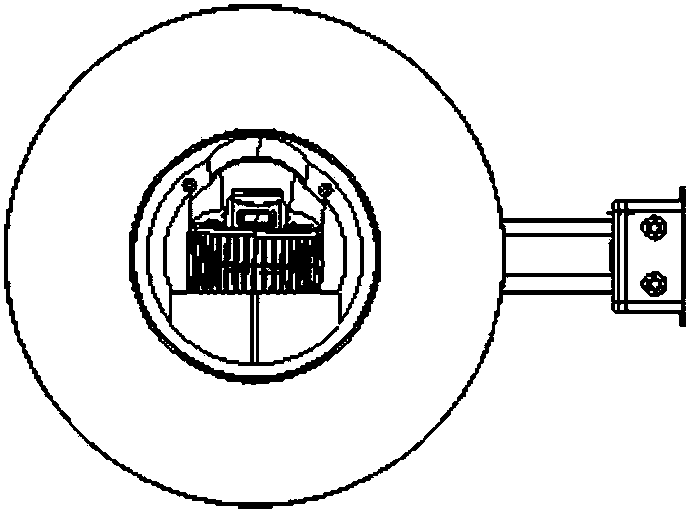

[0034] combine Figure 1 to Figure 4 , the anti-icing camera mainly includes: pan / tilt shell 1, fixing part 2, inverted U-shaped connection part 3, hemispherical cavity 4, observation window 5, infrared night vision lamp 6 and leeward shielding part 7, wherein,

[0035] The cloud platform shell 1 is a hemispherical or semi-ellipsoidal single-layer protective cover, which is fixedly linked at the top of the cover with the connection port of the fixing member 2 through a connection structure, and the cover mouth of the cloud platform shell 1 The end is provided with an edge stretching horizontally, preferably, the stretching length of the edge is 10-15cm; the fixing member 2 is a rectangular or trapezoidal profile structure with a rounded curve on one side, and the narrower end formed by the rounded curve The connection port is provided to connect with the pan-tilt shell 1, and the other end is fixed on the transmission line iron tower. The inverted U-shaped connection part 3 is...

Embodiment 2

[0042] In this embodiment, the structures and connections of the components of the anti-icing camera are the same as those in Embodiment 1, so they will not be described here again.

[0043] A heating device can also be set in the hemispherical cavity 4, which is connected with an external power supply by a wire, and is used to heat the hemispherical cavity 4 and the observation window 5, and the ice-coated surface on the surface of the hemispherical cavity 4 Melting and melting the residual icing on the surface of the observation window 5 that is not removed by the cleaning brush. Therefore, those skilled in the art can understand that, in order to transfer the heat energy of the heating device quickly and at the same time adapt to the alternation of cold and heat in a short period of time, the hemispherical cavity 4 is preferably made of metal material, of course, it can also have good thermal conductivity and can Materials suitable for alternating cold and heat in a short p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Extended length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com