Method and system for impregnating and drying a continuous paper web

A drying and equipment technology, used in progressive dryers, lighting and heating equipment, dryer parts, etc., can solve the problems of not obtaining operational reliability, expensive electrical energy, etc., to prevent cross-linking, maintain maximum temperature, and high evaporation. The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

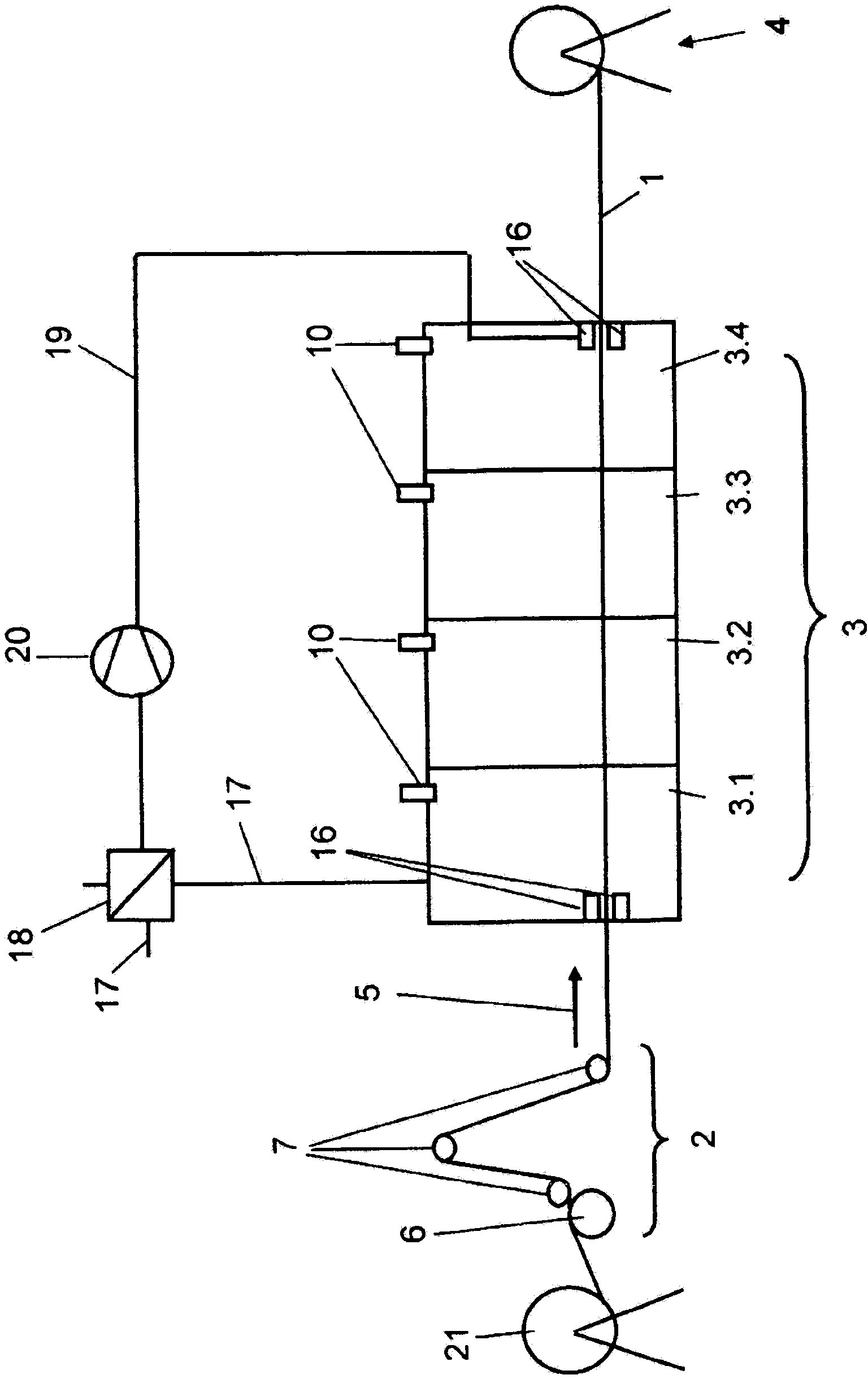

[0026] as from figure 1 As can be seen in , the apparatus for impregnating and drying a continuous paper web 1 comprises a first coating device 2 and a dryer 3 for metered coating of urea resin. A reel 4 for winding up the impregnated paper web 1 , which is conveyed in the direction of the arrow 5 , is preferably connected downstream of the dryer 3 .

[0027] The first coating device 2 comprises a welding roll 6 , a deflection roll 7 and a device (not shown) for conveying the urea resin.

[0028] Here, the dryer 3 comprises four substantially identically constructed drying zones 3.1, 3.2, 3.3, 3.4 in a modular manner and is surrounded by a housing. Between adjacent drying zones of the drying zones 3.1, 3.2, 3.3, 3.4, partitions are arranged respectively.

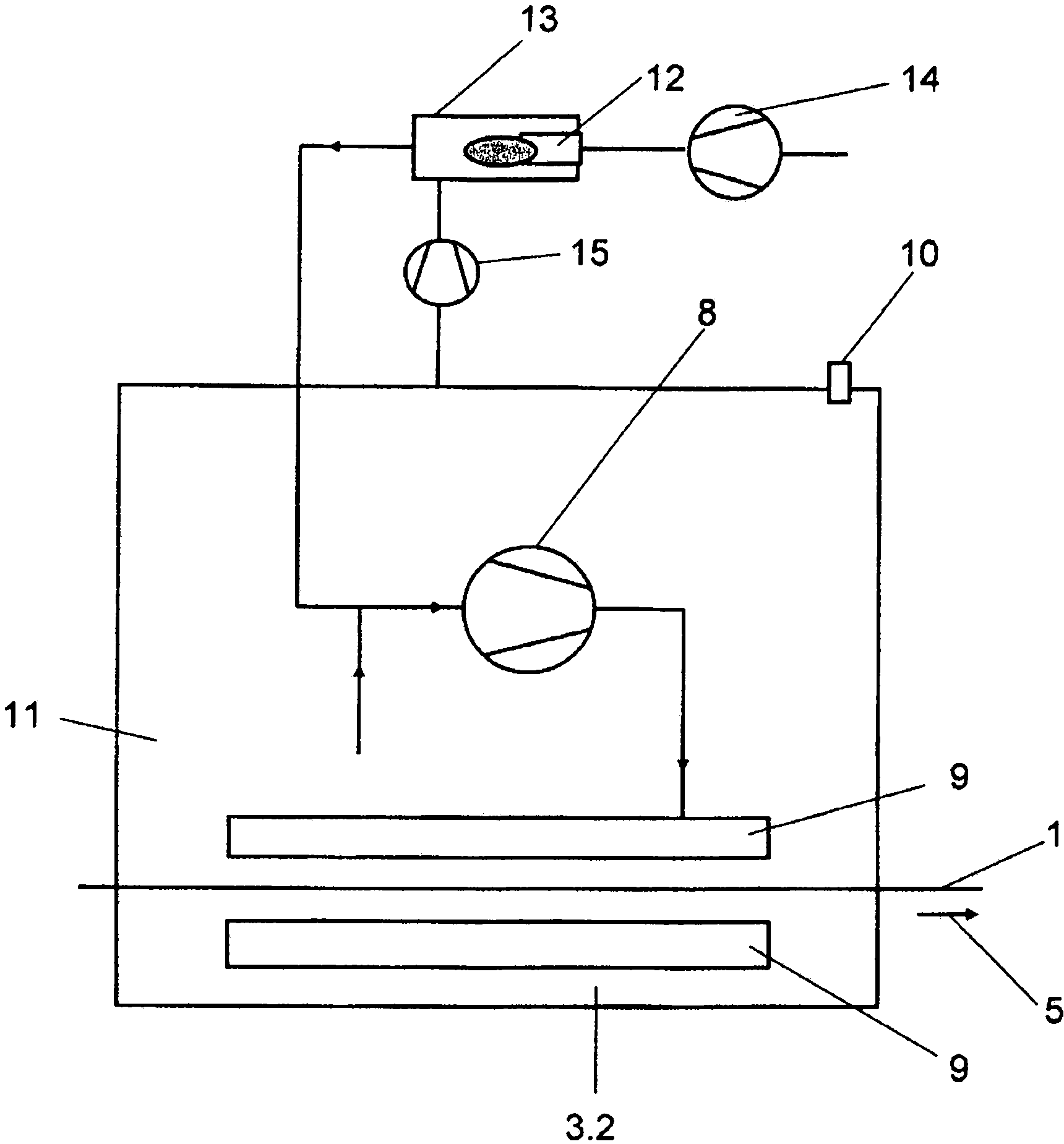

[0029] as from figure 2 As can be seen particularly clearly in , each drying zone 3.1, 3.2, 3.3, 3.4 comprises a circulating air blower 8, arranged above and below the paper web 1, for blowing the air guided as circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com