Method for extracting keratin from feather

A keratin and feather technology, applied in the polymer field, can solve problems such as waste of resources, achieve the effects of easy filtration, improve yield and purity, and reduce hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

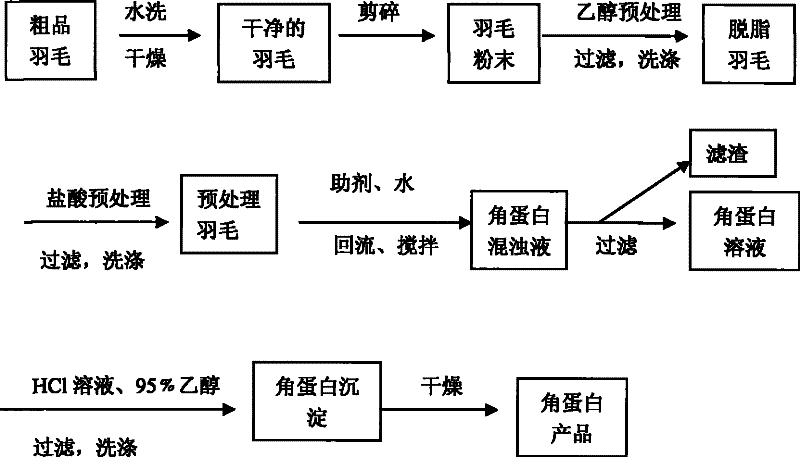

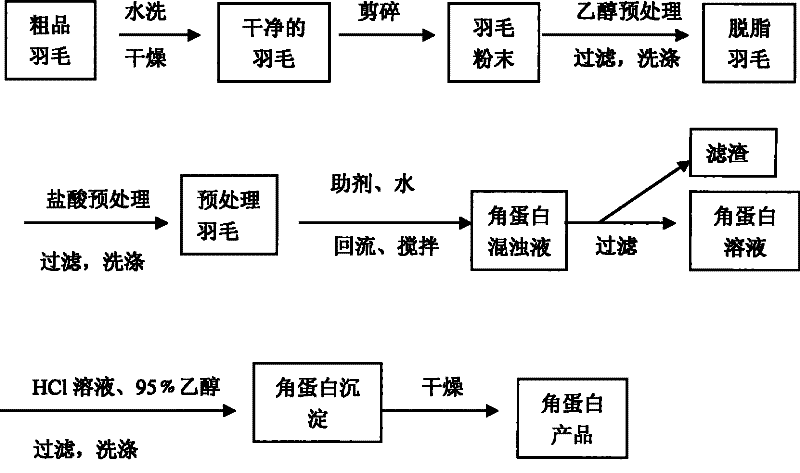

Method used

Image

Examples

Embodiment 1

[0036] Ethanol pretreatment: put 3g of clean feather powder in a round bottom flask, add 100mL of 95% ethanol, stir at 60°C for 2h; filter and wash with 95% ethanol and distilled water several times respectively to obtain degreased feathers.

[0037] Hydrochloric acid pretreatment: put defatted feathers in a flask, add 4mL, 38% concentrated hydrochloric acid, then add 100mL, 95% industrial ethanol and 150mL distilled water, stir at 70°C for 1h; filter, wash with distilled water several times, and dry Get hydrochloric acid to treat feathers.

[0038] Mercaptoethanol reduction: put the hydrochloric acid pretreated feathers into a three-necked flask, add 150mL of distilled water, 0.1g of Tris, 3g of SDS, 7g of urea, and 1mL of mercaptoethanol, protect with nitrogen, and stir at 50°C for 3h. Then filter the undissolved feather residue, and collect the filter residue and filtrate respectively.

[0039] Keratin precipitation: adjust the pH of the filtrate (keratin solution) to 3.0 ...

Embodiment 2

[0042] Ethanol pretreatment: put 3g of clean feather powder in a round bottom flask, add 100mL of 95% ethanol, stir at 70°C for 1 hour; filter and wash with 95% ethanol and distilled water for several times respectively to obtain degreased feathers.

[0043] Hydrochloric acid pretreatment: put defatted feathers in a flask, add 6mL, 36% concentrated hydrochloric acid, then add 100mL, 95% industrial ethanol and 150mL distilled water, stir at 70°C for 1h; filter, wash with distilled water several times, and dry Get hydrochloric acid to treat feathers.

[0044] Mercaptoethanol reduction: put the feathers pretreated with hydrochloric acid in a three-necked flask, add 150mL of distilled water, 0.1g of Tris, 3g of SDS, 7g of urea, 1mL of mercaptoethanol, protect with nitrogen, stir at 50°C for 3h; filter, collect the filter residue and filtrate.

[0045] Keratin precipitation: adjust the pH of the filtrate (keratin solution) to 3.0 with 36% concentrated hydrochloric acid, and a larg...

Embodiment 3

[0048] Ethanol pretreatment: put 5g of clean feather powder in a round bottom flask, add 200mL of 95% ethanol, stir at 70°C for 1 hour; filter, then wash several times with 95% ethanol and distilled water respectively to obtain degreased feathers.

[0049] Hydrochloric acid pretreatment: put the above defatted feathers in a flask, add 10mL, 38% concentrated hydrochloric acid, then add 130mL, 95% industrial ethanol and 250mL distilled water, stir at 70°C for 1h; then filter the feathers again, and wash with distilled water Several times, after drying, get hydrochloric acid to treat the feathers.

[0050] Mercaptoethanol reduction: Put the feathers pretreated with hydrochloric acid into a three-necked flask, add 250mL of distilled water, 0.2g of Tris, 5g of SDS, 12g of urea, and 5mL of mercaptoethanol, protect with nitrogen, and stir at 50°C for 1h; Feather dregs were filtered, and the filter residue and filtrate were collected separately.

[0051] Keratin precipitation: adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com