Joining sheet, electronic component, and producing method thereof

A bonding chip and wiring circuit substrate technology, applied in the bonding chip field, can solve the problems of low impact of solder joints, low bonding reliability, etc., and achieve the effect of inhibiting the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

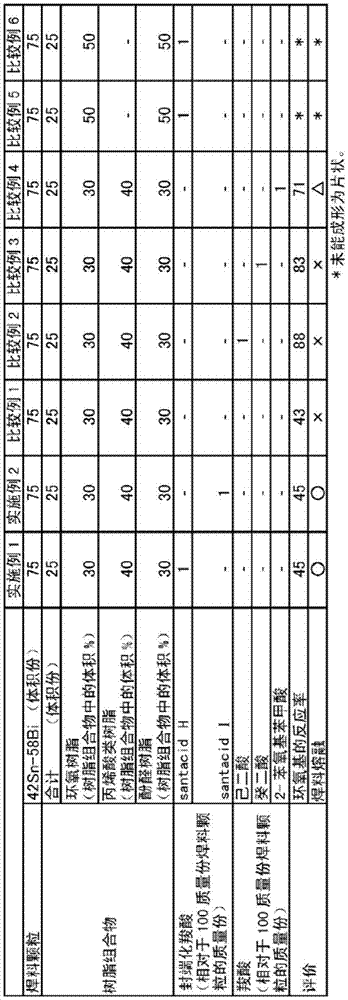

[0116] By adding 30 parts by volume of epoxy resin (Nippon Steel Chemical Co., Ltd., thermosetting resin, YSLV-80XY, curing temperature 150°C), acrylic resin (manufactured by KURARAY CO., LTD, thermoplastic resin, LA POLYMER, softening temperature 110° C.) 40 parts by volume, and 30 parts by volume of a phenolic resin (manufactured by Meiwa Kasei Co., Ltd., curing agent, MEH-7851SS) were mixed to obtain a resin composition. The obtained resin composition and solder particles (Sn / Bi=42% by mass / 58% by mass, melting point of 139° C., spherical shape, average particle diameter of 35 μm) were mixed at a volume ratio of resin composition:solder particles=25:75, Further, a blocked carboxylic acid (manufactured by NOF Corporation, Santacid H, monoalkyl vinyl ether blocked difunctional low molecular weight type carboxylic acid, dissociation temperature 160° C. °C) and kneaded using a kneader to obtain a mixture. The obtained mixture was molded at 125° C. into a sheet having a thickne...

Embodiment 2

[0118] Except that the blocked carboxylic acid (manufactured by NOF Corporation, Santacid H, monoalkyl vinyl ether blocked difunctional low molecular weight type carboxylic acid, dissociation temperature 160°C) was changed to blocked carboxylic acid (NOF Corporation Production, Santacid I, monoalkyl vinyl ether-terminated difunctional carboxylic acid, dissociation temperature 170° C.), a bonding sheet was produced in the same manner as in Example 1.

Embodiment 3

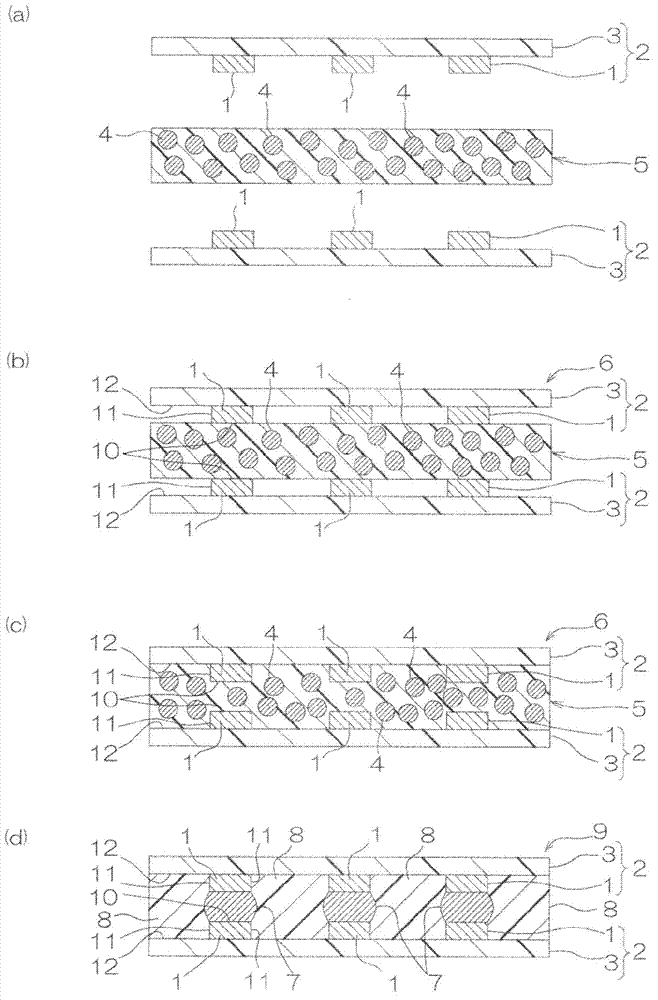

[0152] Example 3 (Performance Test of Solder Melting B of the Bonding Sheet of Example 1)

[0153] Prepare two wired circuit boards (refer to figure 1 (a)). After the two wired circuit boards were arranged so that the corresponding terminals were arranged to face each other with a gap, the bonding sheet of Example 1 was inserted therebetween, and the bonding sheet was brought into contact with the two wired circuit boards to obtain a laminated body ( refer to figure 1 (b)). Next, the obtained laminate was bonded by thermocompression at 125°C and 1 MPa (see figure 1 (c)). Thereafter, it was heated at 170°C for 30 minutes, thereby manufacturing an electronic component (see figure 1 (d)).

[0154] As a result of examining the melting of the solder in this electronic component, it was confirmed that the solder was melting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com