Complete passive cooling system for post-accident reactor cores of large PWR (pressurized water reactor) nuclear power plants

A pressurized water reactor nuclear power plant, passive cooling technology, applied in nuclear power generation, cooling devices, nuclear engineering, etc., can solve problems such as leakage of radioactive materials, inability to discharge residual heat from the core, core melting, etc., to maintain integrity , Improving the anti-aircraft impact ability and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

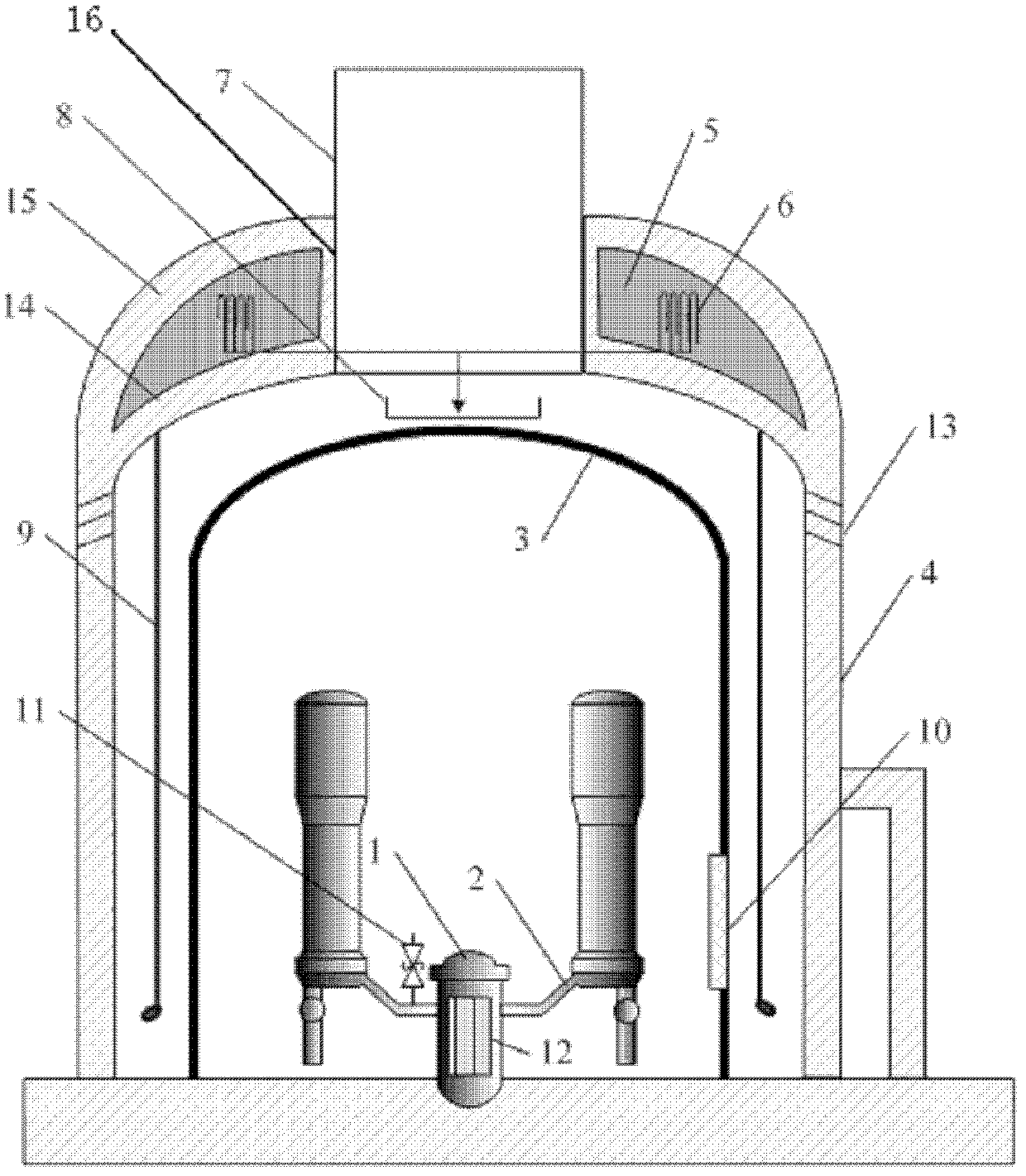

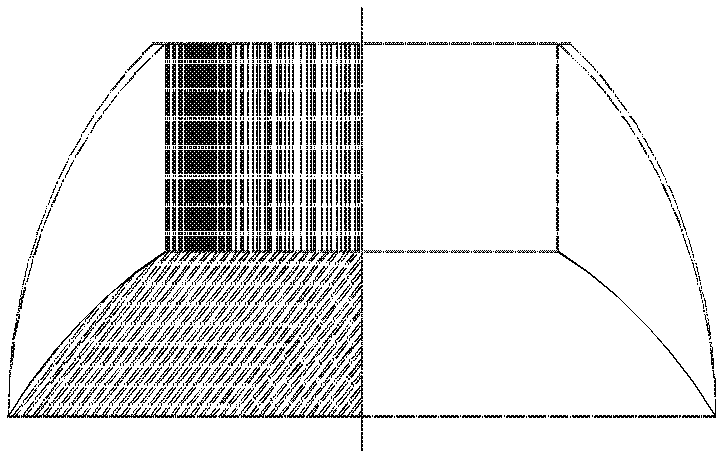

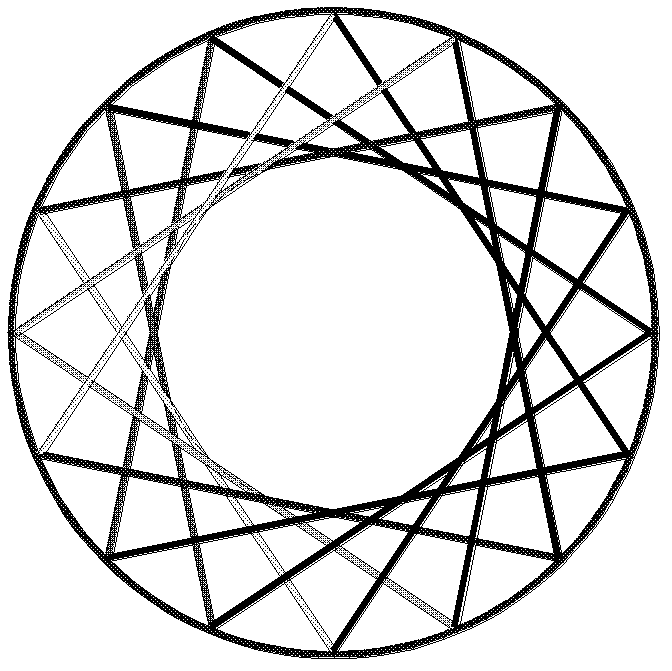

[0024] Such as figure 1 As shown, the shielded factory building 4 is a steel-concrete composite structure, including a cylindrical cylinder and a double-layer structure top. The top of the double-layer structure is formed at the upper end of the cylindrical cylinder, and the top of the double-layer structure includes an inner shell 14 , the housing 15 and the air channel 16. Shield the steel frame on the top of plant building 4, such as figure 2 , 3As shown in and 4, the inner shell 14 is a semi-ellipsoid arch shell, and its semi-ellipsoid arch shell is set on a tensile stress ring beam; the outer shell 15 is a hemispherical arch shell, and its hemispherical arch shell is set on another tensile stress ring beam. stress ring beam. Taking the tensile stress ring beam of the inner shell 14 as the outer circle, and the air flow channel 16 as the inner circle, semi-elliptical arch beams are evenly arranged around the center of the circle at equal angles, and the semi-elliptical...

Embodiment 2

[0026] Such as Figure 5 As shown, the difference from Embodiment 1 is that the inner shell 14 on the top of the shielding plant 4 is conical, and the outer shell 15 is the top of a double-layer steel-concrete composite structure that is cylindrical, and the opening of the cylindrical steel-concrete composite structure is air. The flow channel 16, the cavity formed between the inner shell 14, the outer shell 15 and the air flow channel 16 is the water tank 5, that is, the top of the double-layer steel-concrete composite structure forms the water tank 5. The steel-concrete composite structure of the shielding workshop 4 adopts the compression ring design in the prior art. A cooling water distribution plate 8 is arranged on the top of the containment 3 and in the middle of the shielding building 4 , and the cooling water distribution plate 8 is suspended on the pressure ring of the shielding building 4 .

Embodiment 3

[0028] Such as Figure 6 As shown, the difference from Embodiment 1 is that the top inner shell 14 of the shielded factory building 4 is semi-ellipsoidal, and the outer shell 15 is the top of the double-layer steel-concrete composite structure of the cylindrical shape, and the cylindrical steel-concrete composite structure opening is formed as the air at the same time. The flow channel 16, the cavity formed between the inner shell 14, the outer shell 15 and the air flow channel 16 is the water tank 5, that is, the top of the double-layer steel-concrete composite structure forms the water tank 5. A cooling water distribution plate 8 is installed on the top of the steel containment vessel 3 and in the middle of the shielded building 4 , and the cooling water distribution plate 8 is suspended on the arched shell of the inner shell 14 .

[0029] When an accident occurs in the reactor, if the pressure vessel 1 is ruptured or the pressure boundary 2 of the primary circuit is rupture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com