Metal oxide semiconductor electrical parameter testing device and method of manufacture

A technology of oxide semiconductors and electrical parameters, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as threshold voltage drift, change of interface state, positive or negative charges cannot be released, etc., to achieve Threshold voltage change is small, and the effect of improving the interface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

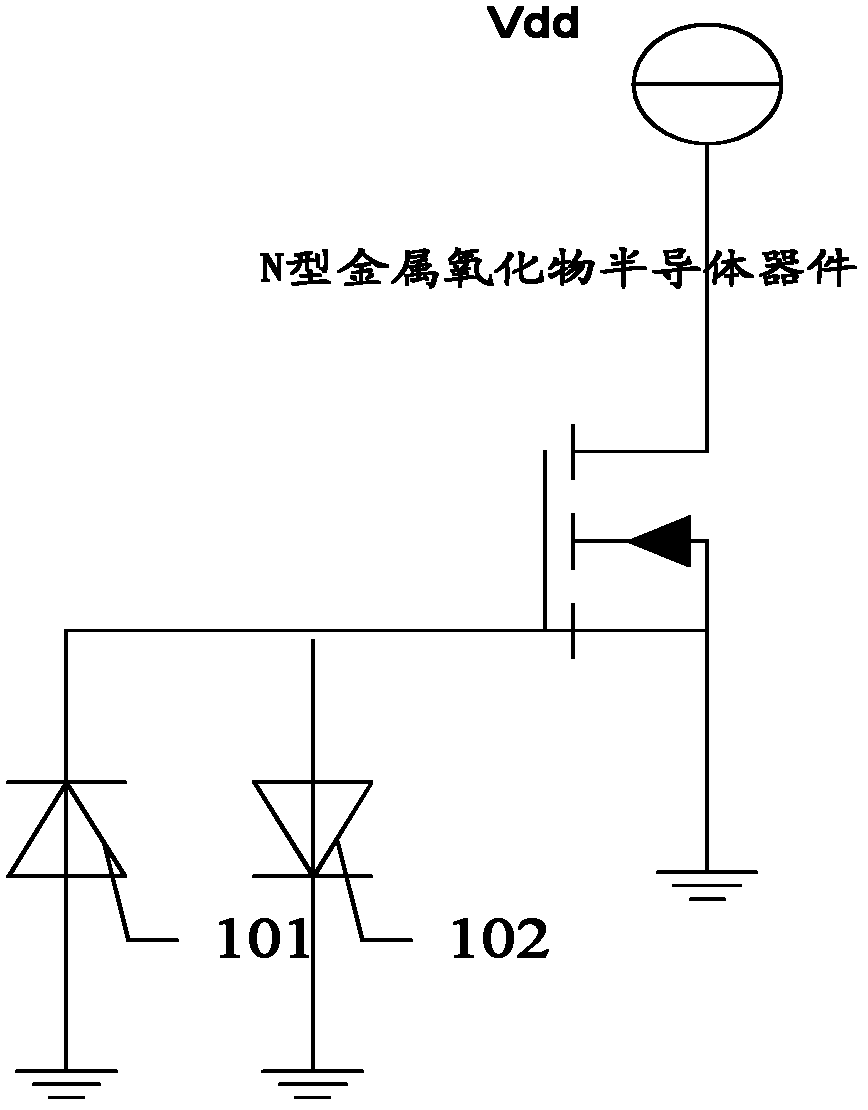

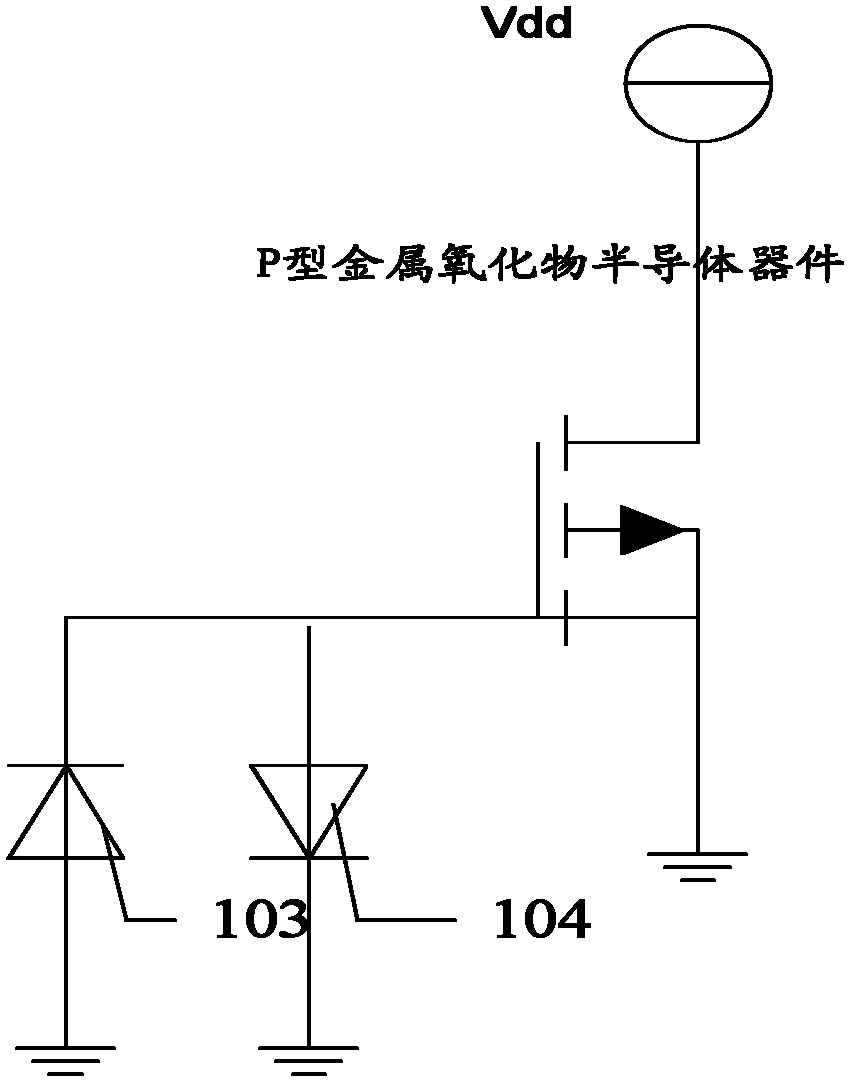

[0032] In the embodiment of the present invention, in the metal oxide semiconductor electrical parameter test device with metal as the gate, two parallel reverse diodes are connected through the gate to release the charge introduced by the gate due to plasma damage, thereby improving the interface state and making the threshold test The values actually reflect the thresholds of the semiconductor devices in the circuit.

[0033] The schematic diagram of the composition of the N-type metal oxide semiconductor electrical parameter test device and the P-type metal oxide semiconductor electrical parameter test device in the first embodiment of the present invention is as follows Figure 1a and Figure 1b shown.

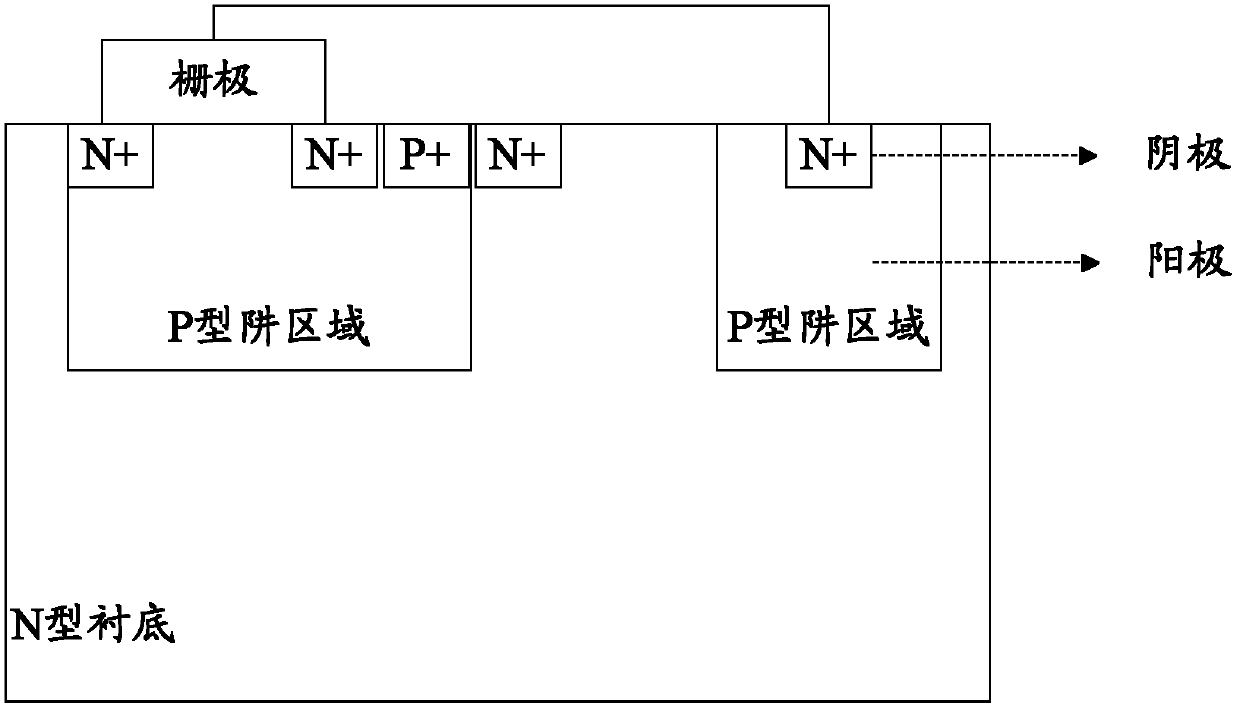

[0034] Figure 1a Among them, in the N-type metal oxide semiconductor electrical parameter test device with metal as the gate, the first PN structure formed by the first P-type well region of the N-type substrate and the first N+ region forms the first diode 101, so The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com