Cooling method for treating system

A processing system and reactor technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as consuming a long cooling time, reducing the production capacity of PECVD system, and affecting the utilization rate of PECVD system equipment , to achieve the effect of improving equipment utilization rate, reducing cooling cost and shortening cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

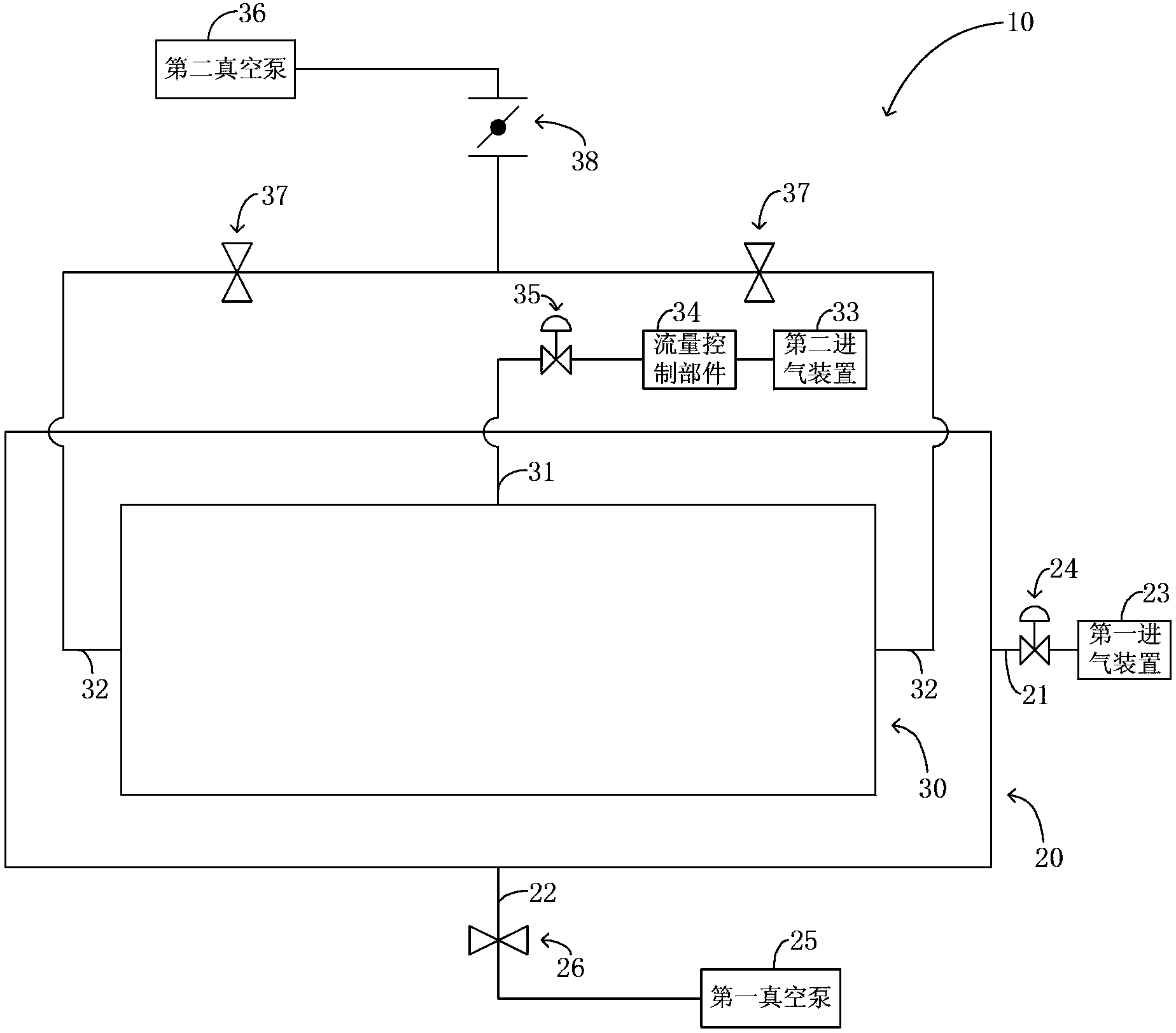

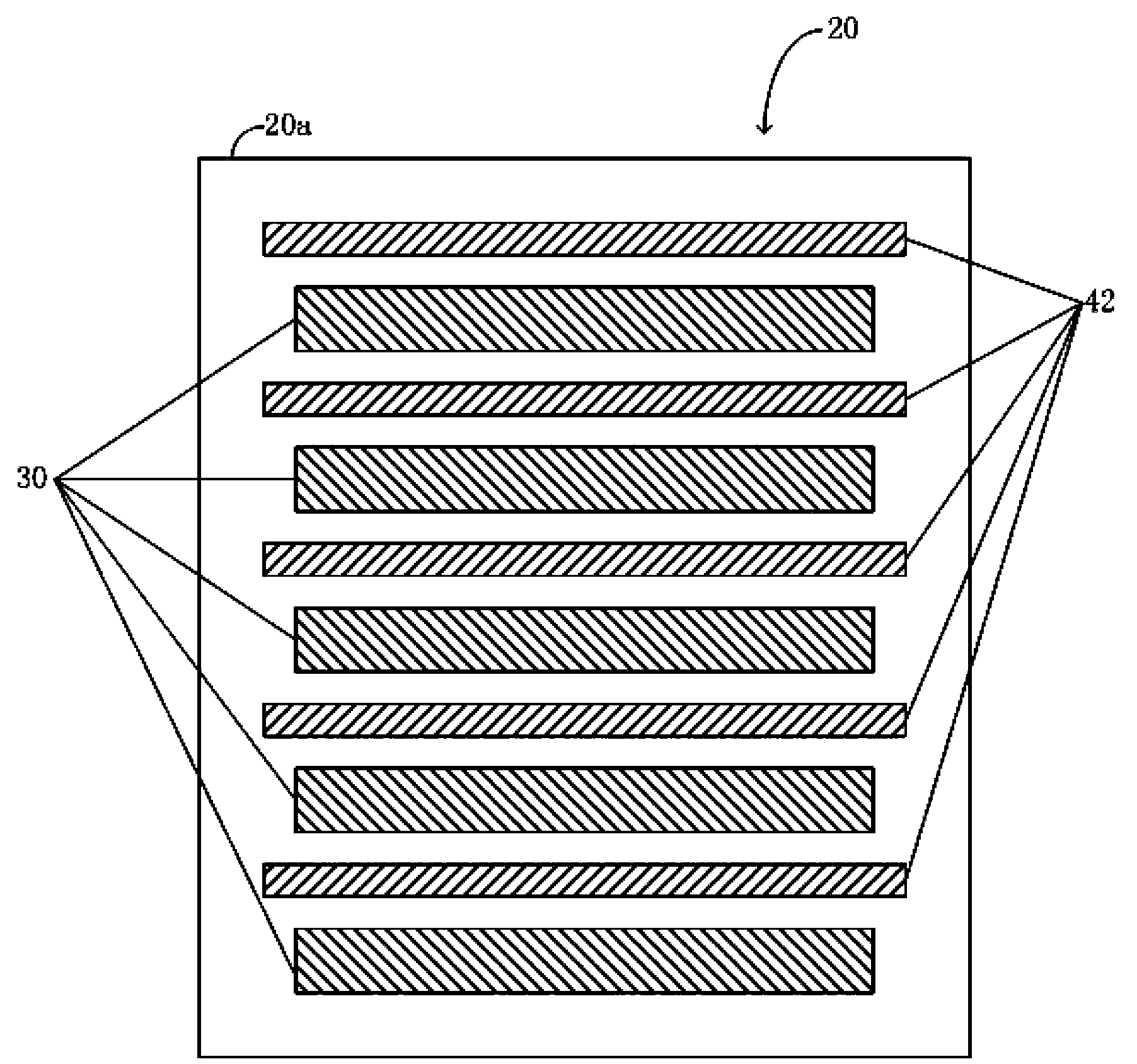

[0067] The processing system is a PECVD system. During normal operation, the plasma reactor of the PECVD system is heated, and gas is introduced into the second air inlet of the plasma reactor to keep the temperature at 160 °C, and at the same time, the upper electrode, the RF high frequency is applied to the lower electrode to plasma the gas in the plasma reactor, and the solar cell thin film is produced on the glass substrate by PECVD process.

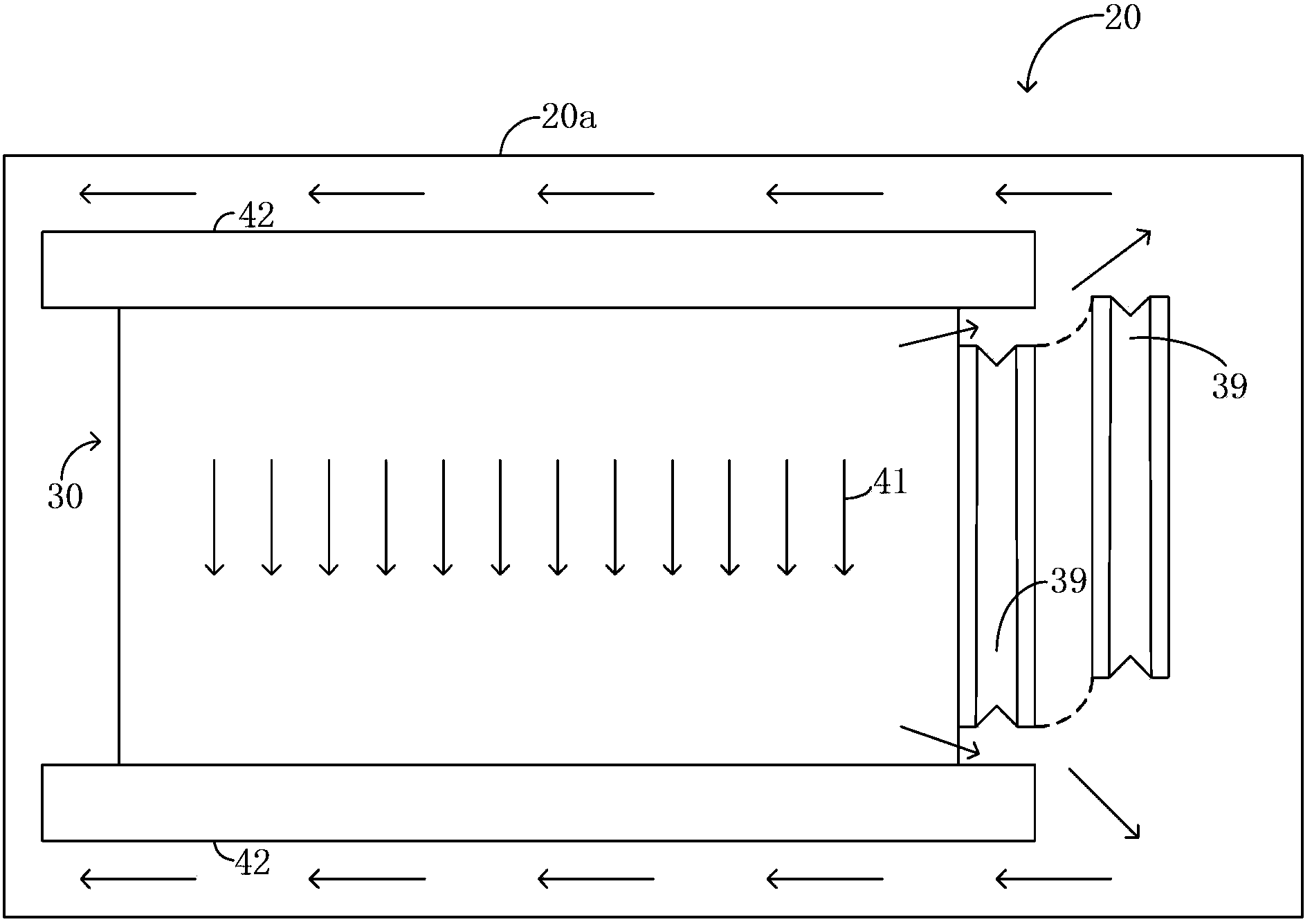

[0068] When the PECVD system needs to be maintained, stop heating the plasma reactor, apply RF high frequency to the upper electrode and the lower electrode in the plasma reactor, feed hydrogen into the second air inlet of the plasma reactor, and Keep the door between the plasma reactor and the vacuum chamber closed, hydrogen can enter the vacuum chamber through the gap between the door and the plasma reactor, and close the plasma reactor when the pressure of the plasma reactor reaches 2.5mbar The second air inlet, the second air ou...

Embodiment 2

[0070] The processing system is a PECVD system. During normal operation, the plasma reactor of the PECVD system is heated, and gas is introduced into the second air inlet of the plasma reactor to keep the temperature at 160 °C, and at the same time, the upper electrode, the RF high frequency is applied to the lower electrode to plasma the gas in the plasma reactor, and the solar cell thin film is produced on the glass substrate by PECVD process.

[0071] When the PECVD system needs to be maintained, stop heating the plasma reactor, apply RF high frequency to the upper electrode and the lower electrode in the plasma reactor, feed hydrogen into the second air inlet of the plasma reactor, and Keep the door between the plasma reactor and the vacuum chamber in a closed state, hydrogen can enter the vacuum chamber through the gap between the door and the plasma reactor, and when the pressure of the plasma reactor reaches 5mbar, close the The second air inlet, the second air outlet,...

Embodiment 3

[0073] The processing system is a PECVD system. During normal operation, the plasma reactor of the PECVD system is heated, and gas is introduced into the second air inlet of the plasma reactor to keep the temperature at 160 °C, and at the same time, the upper electrode, the RF high frequency is applied to the lower electrode to plasma the gas in the plasma reactor, and the solar cell thin film is produced on the glass substrate by PECVD process.

[0074] When the PECVD system needs to be maintained, stop heating the plasma reactor, apply RF high frequency to the upper electrode and the lower electrode in the plasma reactor, feed hydrogen into the second air inlet of the plasma reactor, and Keep the door between the plasma reactor and the vacuum chamber closed, hydrogen can enter the vacuum chamber through the gap between the door and the plasma reactor, and when the pressure of the plasma reactor reaches 6mbar, close the The pressure of the second air inlet, the second air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com