Light emitting diode encapsulation, PCB type radiating substrate used for light emitting diode encapsulation and manufacturing method of PCB type radiating substrate

A technology for heat-dissipating substrates and LED packaging, applied in printed circuit manufacturing, electrical components, circuits, etc., can solve unresolved problems, luminous efficiency, service life of heat-dissipating function, manufacturing cost, assembly yield, simplified manufacturing process, and difficulty in meeting requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

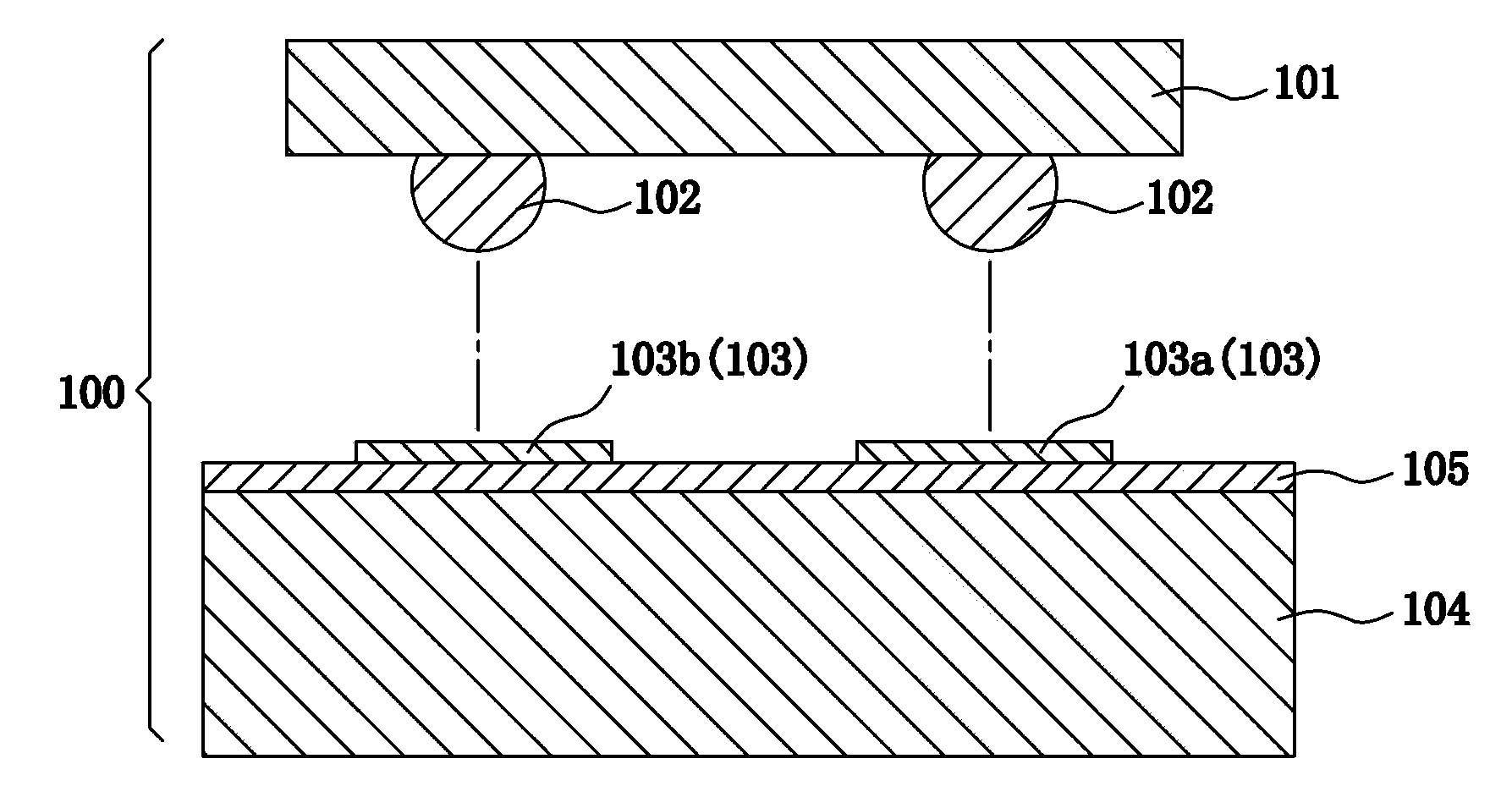

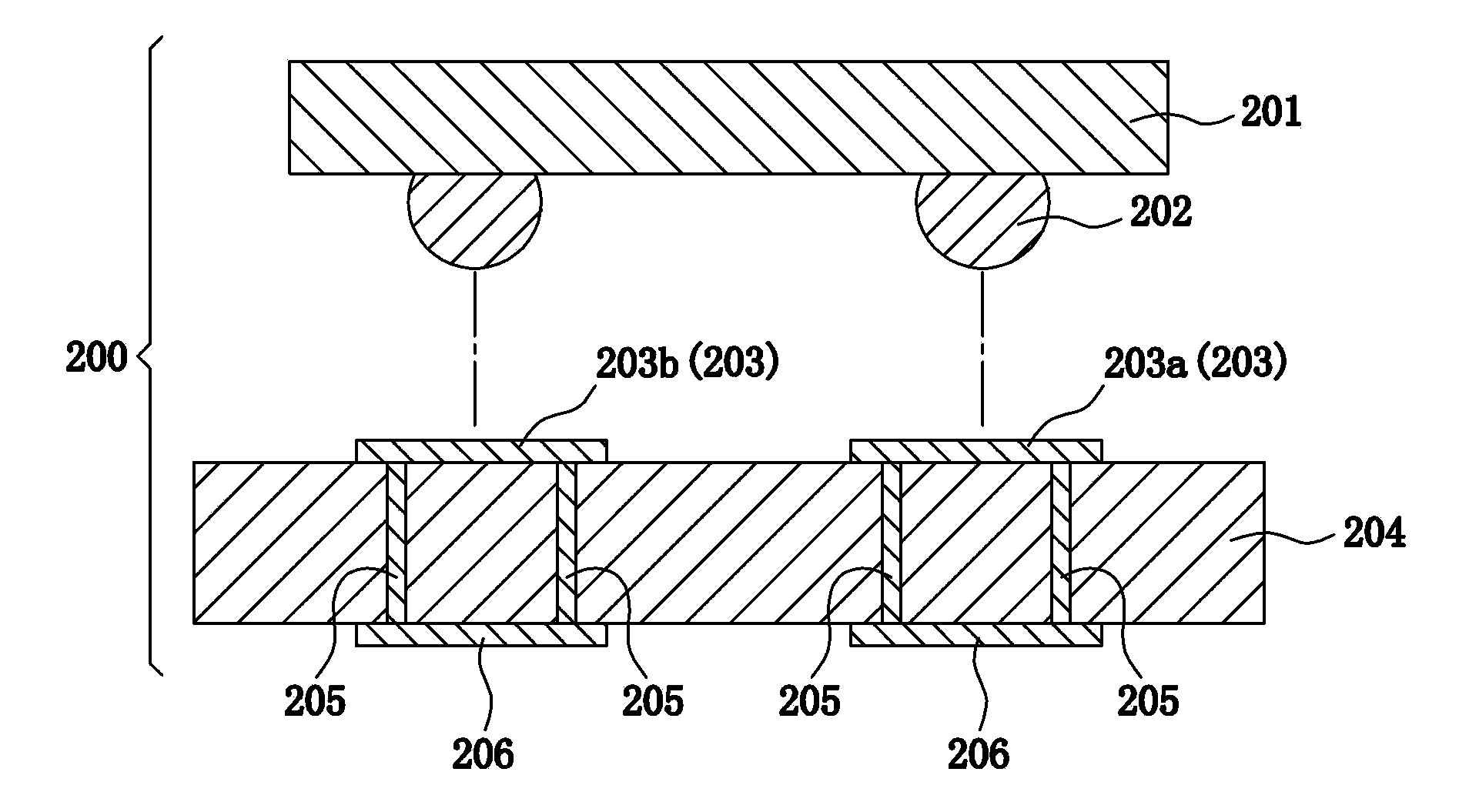

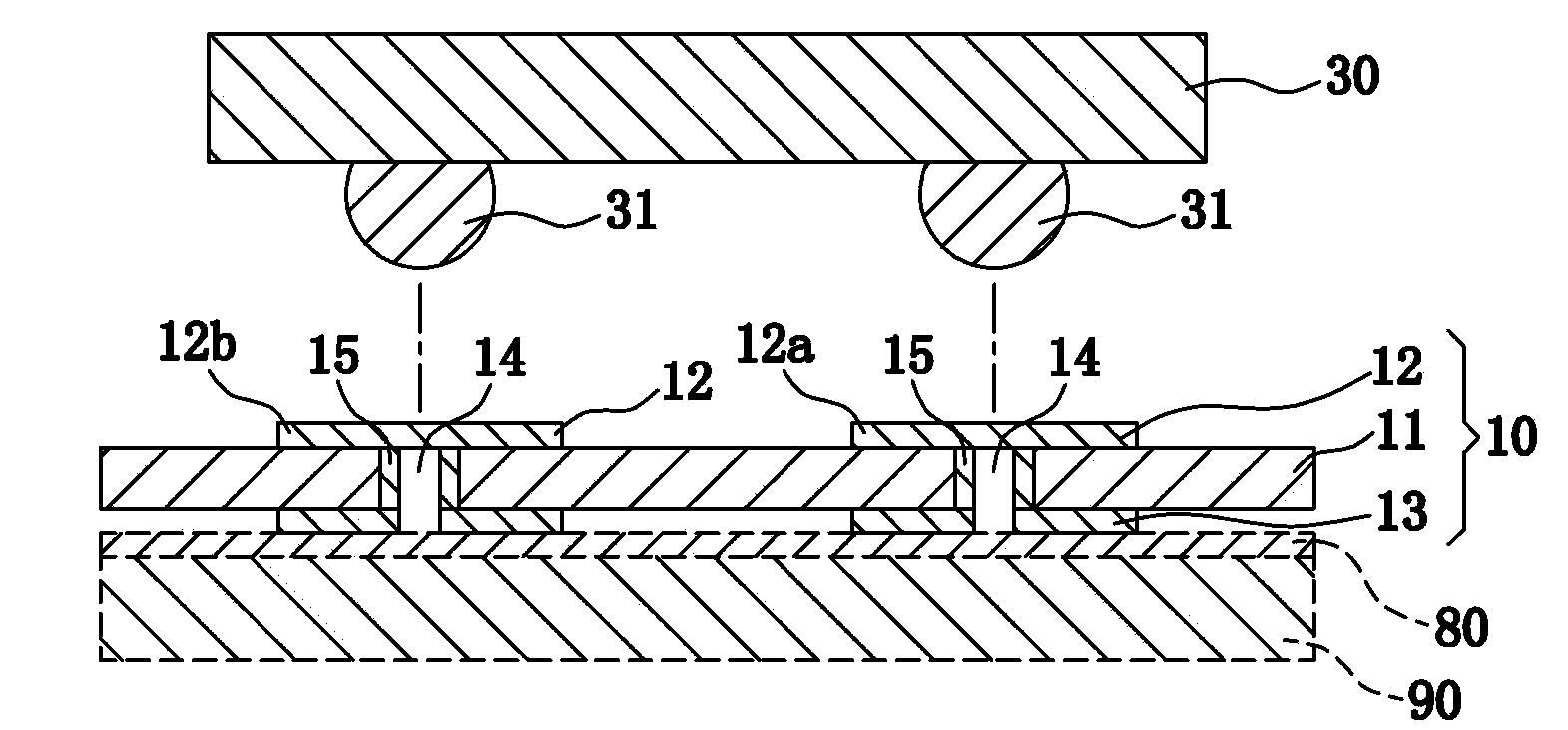

[0049] refer to Figure 3-10 As shown, they are schematic cross-sectional structural views of multiple embodiments of the PCB heat dissipation substrate and the formed LED package (LED package) of the present invention. The PCB type heat dissipation substrate 10 of the present invention is as image 3 As shown, it is made by using a printed circuit board (PCB, Printed Circuit Board) as Figures 11A-11E As shown (to be described later), it includes an insulating layer 11, a first circuit layer 12 and a second circuit layer 13; wherein the first circuit layer 12 is provided on the upper surface of the insulating layer 11 for light emitting The diode (LED) die 30 can be flip-chip (Flip Chip) such as Figure 4 , 6 As shown or the wire (Wire bond) method is as follows Figure 8 , 10 As shown, it is electrically connected on the PCB heat dissipation substrate 10 to form an LED package such as Figure 4 , 6 flip-chip LED packages as shown 40, 50 or as Figure 8 , 10 The wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com