Line pattern manufacturing method

A technology of circuit patterns and manufacturing methods, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, containing printed electrical components, and secondary processing of printed circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

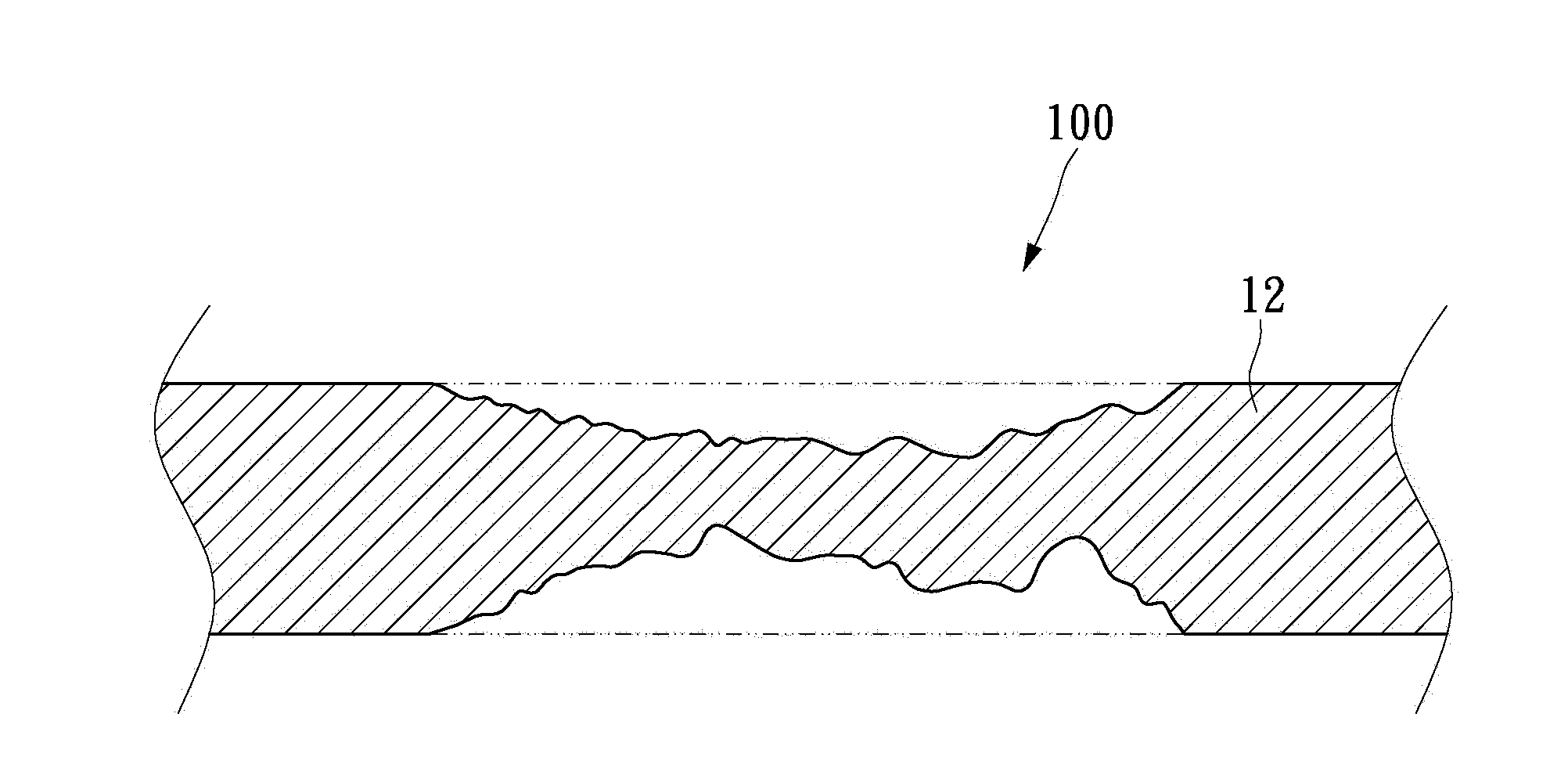

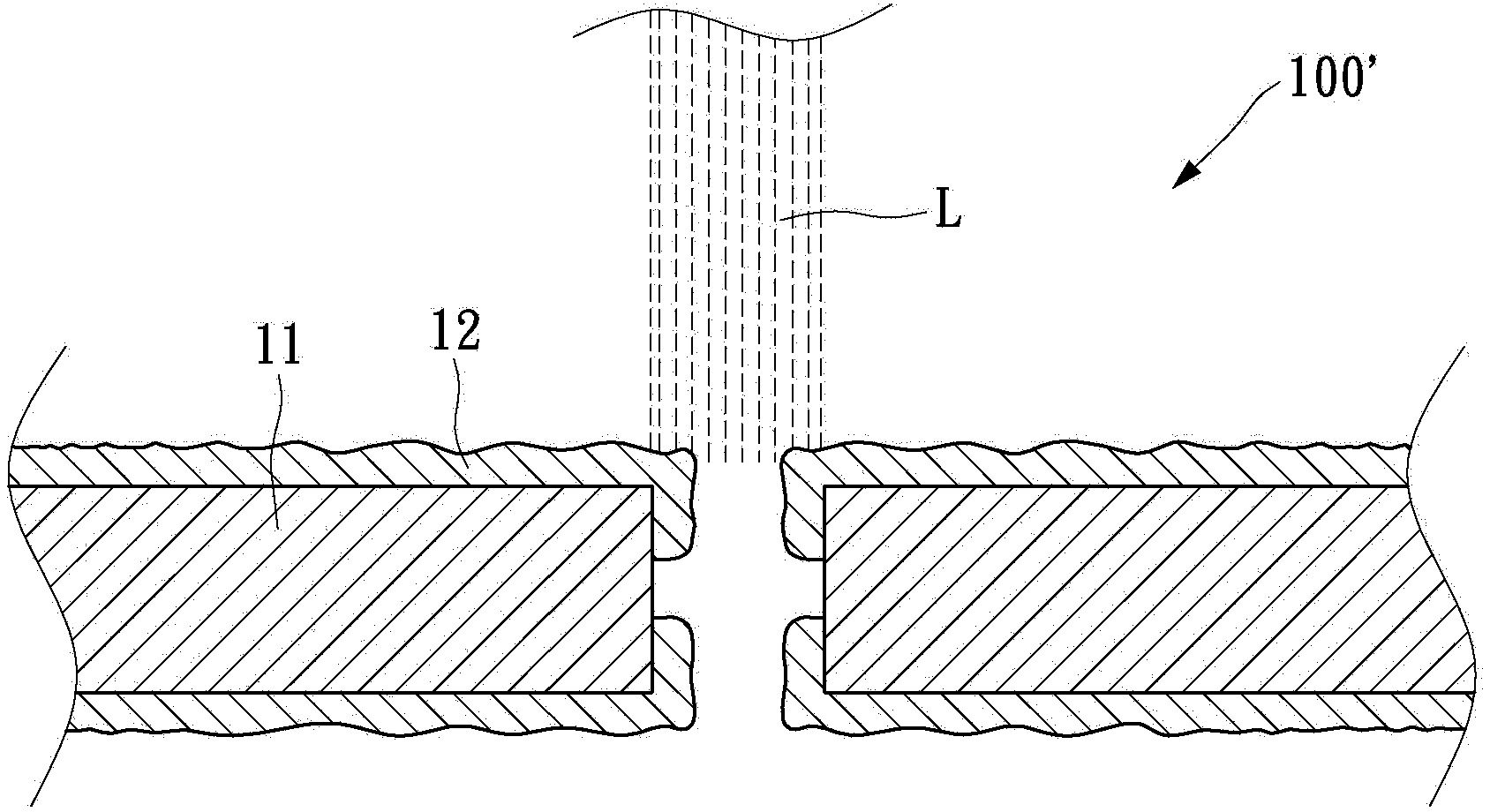

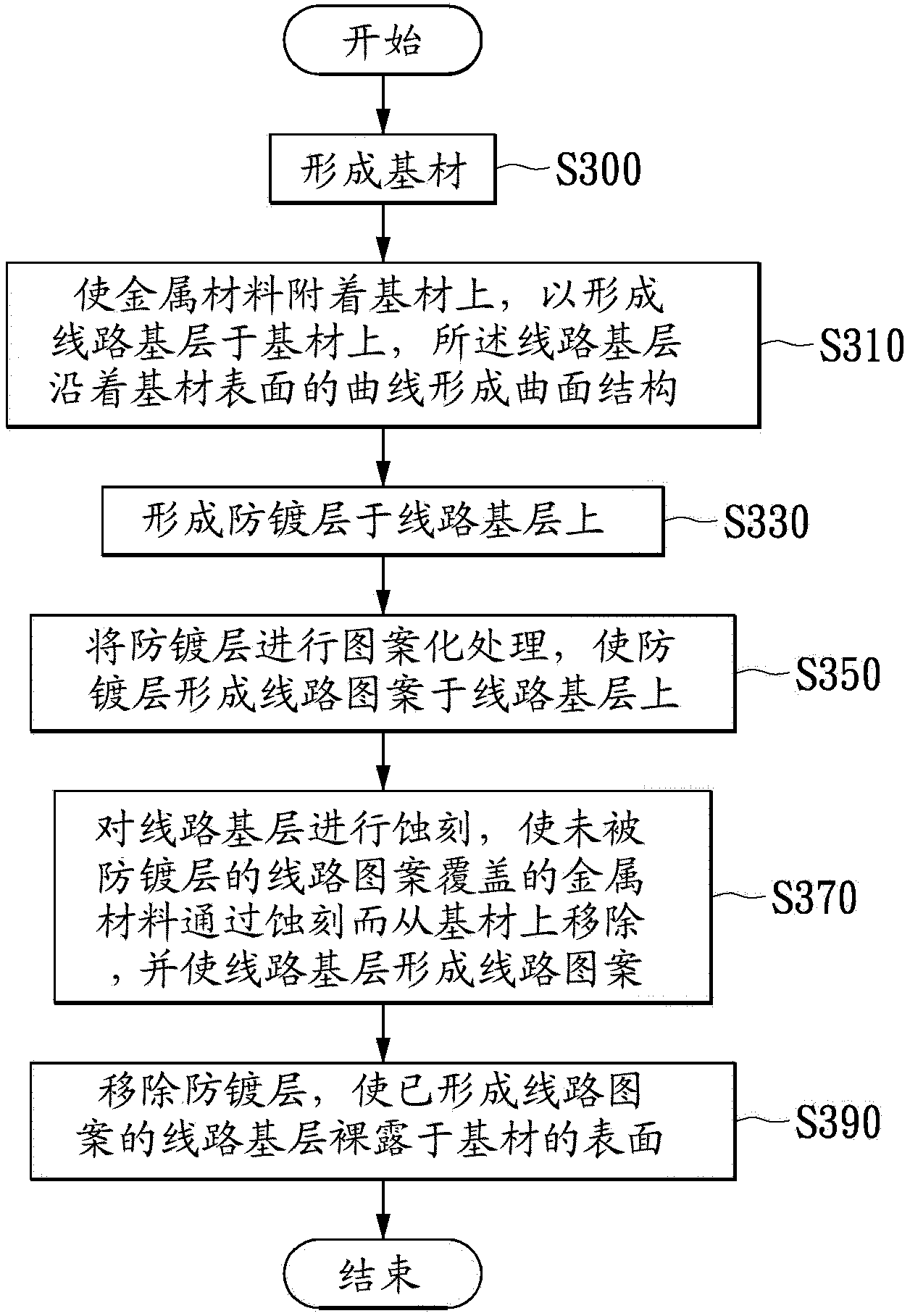

[0026] [Example of Manufacturing Method of Circuit Pattern]

[0027] The manufacturing method of the circuit pattern in the embodiment of the present invention can form a three-dimensional patterned or curved antenna structure, or a circuit pattern for other purposes on a commonly used substrate. The manufacturing method of the circuit pattern in the embodiment of the present invention is described by taking the manufacture of the antenna structure as an example, but the present invention is not limited to the manufacture of the antenna structure. In this embodiment, the base material is, for example, a case of a smart phone, and the case of a smart phone is usually made of plastic or glass. However, the present invention does not therefore limit the type of substrate. In order to provide sufficient bonding force of the antenna structure on the base material, this embodiment is described by taking the manufacture of the antenna structure on the casing as an example.

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com