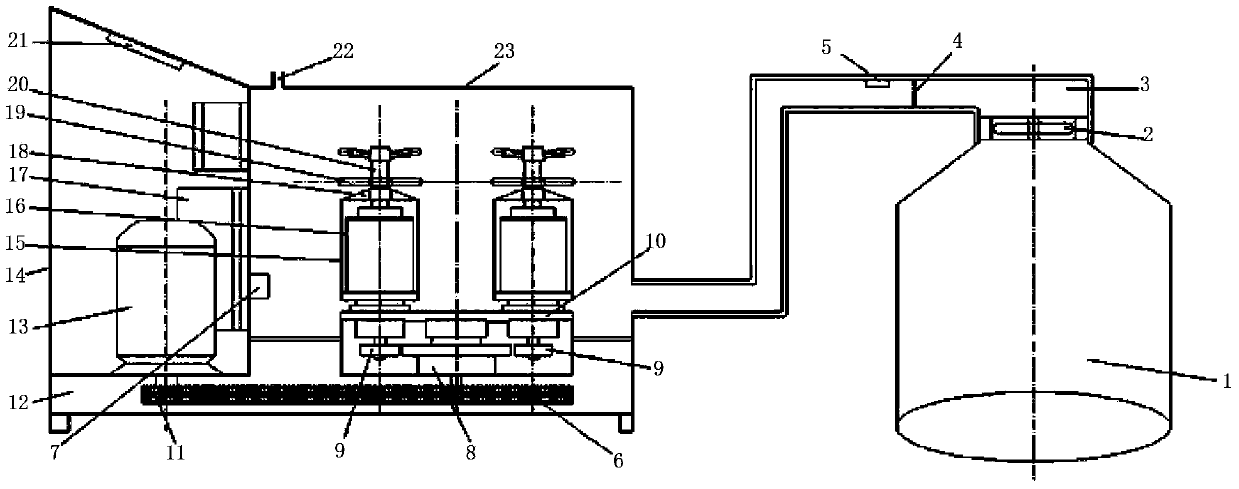

Low-temperature ball-milling experimental apparatus

A low-temperature ball milling and experimental device technology, applied in grain processing and other directions, can solve the problems of increased energy consumption and prolonged ball milling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A ball milling experiment of silicon powder at -150°C was carried out.

[0034] First, put silicon powder with a purity > 99.9% and a particle size of 200 mesh into a stainless steel ball milling tank with a ball-to-material ratio of 10:1. Vacuum the ball milling tank and inject Ar gas to prevent the powder from being oxidized during the ball milling process. Then assemble the jig and cover the airtight box. Then turn on the low-temperature air extractor and adjust the power of the air extractor to extract low-temperature gas, adjust the power of the mesh heater, and check the temperature display of the low-temperature first temperature detector, which is around -170°C, and the cold air enters along with the low-temperature insulation air duct Cool the ball mill insulation cabin and ball mill tank in the sealed box of the ball mill, and then observe the second temperature measuring probe in the sealed box, which shows that the temperature is -150°C. After 20 minutes of ...

Embodiment 2

[0036] A ball milling experiment of pure aluminum powder at -196°C was carried out.

[0037] First, put pure aluminum powder with a purity >99.9% and a particle size of 400 mesh into a stainless steel ball mill tank with a ball-to-material ratio of 20:1. Vacuum the ball mill jar and feed Ar gas to prevent the powder from oxidizing during the ball milling process. Then assemble the jig and cover the airtight box. Then turn on the low-temperature air extractor and adjust the power of the air extractor to extract low-temperature gas. The cold air enters the sealed box of the ball mill along with the low-temperature heat preservation air duct to cool the heat preservation cabin and the ball mill tank of the ball mill. Then observe the two temperature measuring probes, which show that the temperature is -196°C, keep warm for 20 minutes, start the ball mill, adjust the speed to 500r / min, and stop the ball mill after 5 hours. The obtained pure aluminum powder product is nano crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com