Winding method for integral-type large-aperture polyolefin-wound solid-wall inspection well

A polyolefin and large-diameter technology, which is applied in the winding field of integral large-diameter polyolefin winding solid-wall inspection wells, can solve the problems of long molding time, high cost, and easy generation of voids, and achieves high overall structural strength and molding. The effect of short time and no deformation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

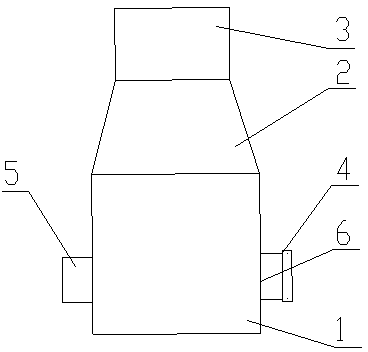

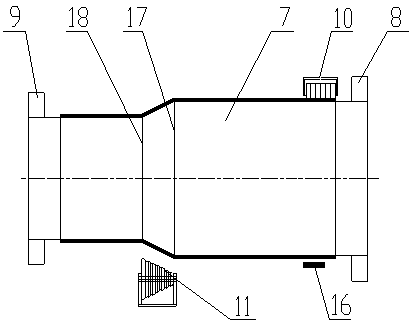

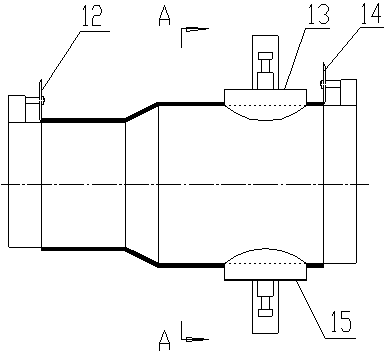

[0023] In this embodiment, the integral large-diameter polyolefin winding solid wall inspection well, such as figure 1 As shown, it consists of three parts from top to bottom, that is, the cylindrical well chamber 1 at the lower end, the conical closing mouth 2 on the upper part of the well chamber 1, the wellbore 3 on the upper part of the conical closing mouth 2, the well chamber 1, the conical closing mouth 2, The shaft 3 is made of the same material into an integrated structure, and the material is polyethylene as the main material plus reinforcing fibers with a content of ≤3%. In the direction perpendicular to the axis of the well chamber 1, there is a corresponding connecting pipe fitting opening 6, and the two connecting pipe fitting openings 6 are respectively welded with the socket pipe fittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com