A composite electrical film and its preparation method

A technology of composite conductive film and conductive material, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problems of reducing the stability of conductive film, poor bonding of metal layer, poor conductivity, etc. Achieve the effect of low cost, high tensile strength and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

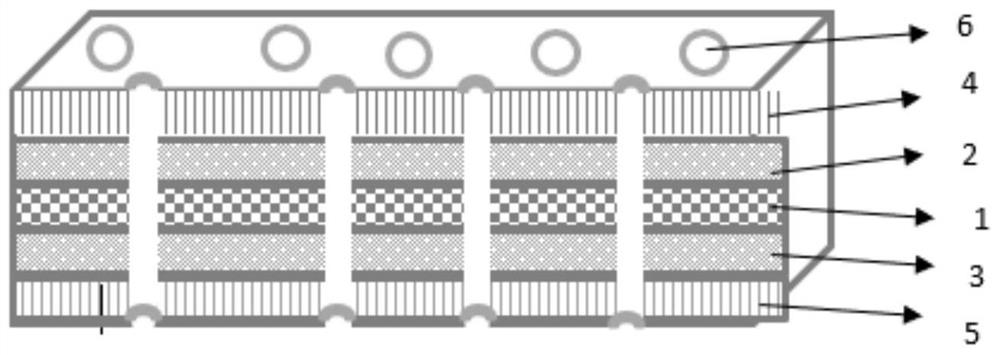

[0036] A high-conductivity composite conductive film, comprising an insulating layer, a first reinforcing layer and a second reinforcing layer arranged on both sides of the insulating layer, a first metal layer and a second reinforcing layer arranged on one side of the first reinforcing layer and the second reinforcing layer respectively The second metal layer, the through holes provided through the insulating layer, the first reinforcement layer, the second reinforcement layer, the first metal layer and the second metal layer, and the conductive material filled in the through holes, the The insulating layer is a composite film of polyethylene terephthalate and 25wt% carbon fiber, and the first reinforcing layer and the second reinforcing layer are Al 2 O 3 layer, the first metal layer and the second metal are Al metal layers.

[0037] The preparation method of the composite conductive film comprises the following steps:

[0038] 1. Preparation of organic / inorganic composite...

Embodiment 2

[0046] The preparation method is the same as that of Example 1, except that the pore density of S3 in Example 1 is 5 / cm 2 .

[0047] The prepared flexible porous conductive film is bent 180° with a bending radius of 1 cm, which can be bent more than 300 times, and the conductivity is about 7.4×10 4 s / m, tensile strength is about 94MPa.

Embodiment 3

[0049] The preparation method is the same as that of Example 1, except that the pore density of S3 in Example 1 is 25 / cm 2 .

[0050] The prepared flexible porous conductive film is bent 180° with a bending radius of 1 cm, which can be bent more than 300 times, and the conductivity is about 8.1×10 4 s / m, tensile strength is about 78MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com