Baked-fragrance-type jujube essence and preparation method thereof

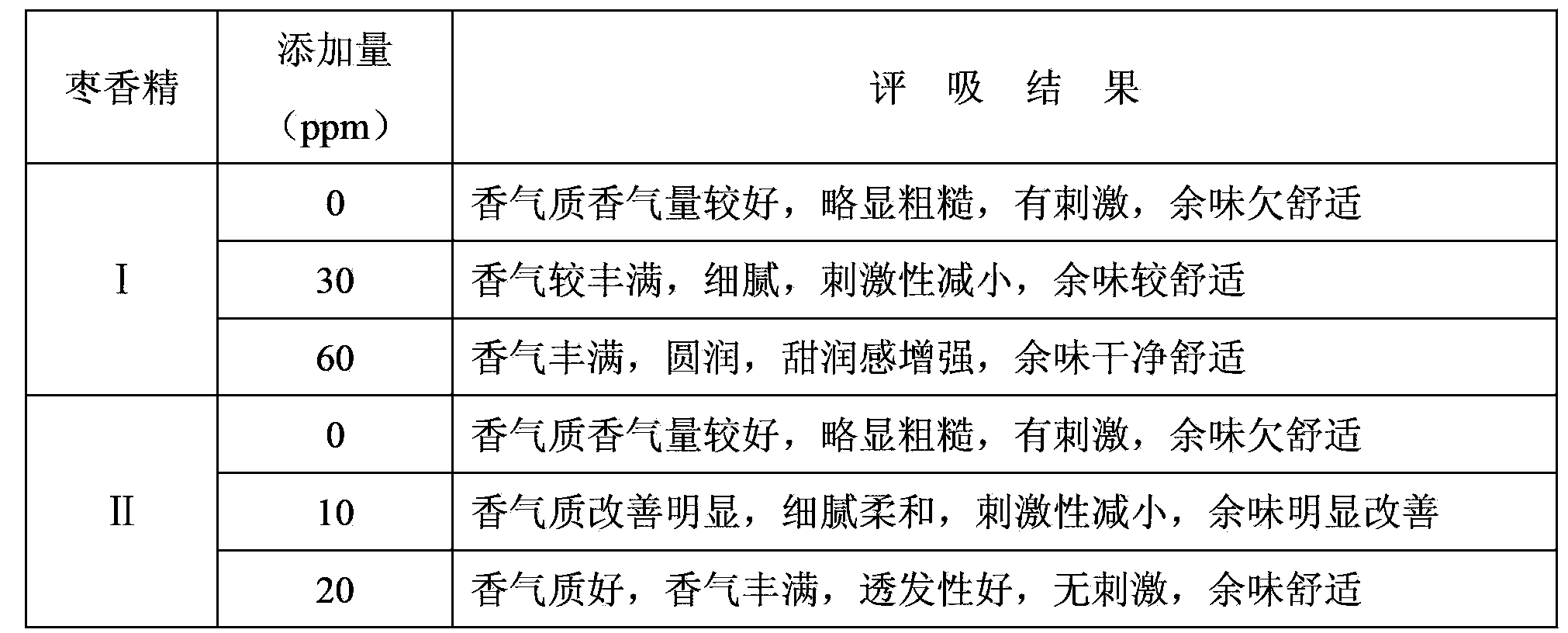

A technology of jujube flavor and roasted flavor, which is applied in the direction of essential oil/flavor, fat production, tobacco, etc., can solve the problems of less preparation and application of jujube flavor, no natural roasted jujube flavor, etc., and improve the quality of cigarettes , Enrich the aroma of smoke, increase the effect of burnt and sweet aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Raw material pretreatment: wash the jujube with water, remove the core, and crush;

[0020] (2) Enzymolysis: Put the pulverized raw jujube in a steam-heatable reaction vessel with a stirring and condensing device, add deionized water 3 times its mass, then add cellulase and pectinase, and the natural pH value, stirring at 50°C for 3 hours; then adjust the pH value to 6.5-7.5 with saturated NaOH solution, add lipase and lipoxygenase, and stir at 40°C for 2 hours to obtain the enzymolysis solution; the raw material jujube , the mass ratio of cellulase, pectinase, lipase and lipoxygenase is 100:0.1:0.1:0.01:0.01;

[0021] (3) High temperature reaction: Add propylene glycol to the enzymolysis solution obtained in step (2); start stirring and condensing water, and heat distillation to collect the distillate; when the reaction temperature reaches the end point of 115°C, change the heating distillation to heating reflux, Reflux reaction for 30 minutes; stop heating, turn ...

Embodiment 2

[0032] (1) raw material pretreatment: the jujube is washed with water, pitted and pulverized;

[0033] (2) Enzymolysis: put the pulverized raw dates in a steam-heatable reaction vessel with stirring and condensing device, add deionized water 5 times its mass, then add cellulase and pectinase, and the value, stirring at 50°C for 2 hours; then adjusting the pH value to 6.5-7.5 with saturated NaOH solution, adding lipase and lipoxygenase, and stirring at 40°C for 2 hours to obtain the enzymolysis solution; the raw material jujube , the mass ratio of cellulase, pectinase, lipase and lipoxygenase is 100:0.1:0.1:0.015:0.015;

[0034] (3) High temperature reaction: add glycerin to the enzymolysis solution obtained in step (2); turn on stirring and condensing water, and heat distillation to collect the distillate; when the reaction temperature reaches the end point temperature of 120°C, change the heating distillation to heating reflux , reflux reaction for 40min; stop heating, turn ...

Embodiment 3

[0037] (1) Raw material pretreatment: wash the jujube with water, remove the core, and crush;

[0038] (2) Enzymatic hydrolysis: put the pulverized raw dates in a steam-heatable reaction vessel with a stirring and condensing device, add deionized water twice its mass, and then add cellulase and pectinase, at natural pH value, stirring at 50°C for 3 hours; then adjust the pH value to 6.5-7.5 with saturated NaOH solution, add lipase and lipoxygenase, and stir at 40°C for 3 hours to obtain the enzymolysis solution; the raw material jujube , the mass ratio of cellulase, pectinase, lipase and lipoxygenase is 100:0.1:0.1:0.008:0.008;

[0039] (3) High temperature reaction: Add propylene glycol to the enzymolysis solution obtained in step (2); start stirring and condensing water, and heat distillation to collect the distillate; when the reaction temperature reaches the end point temperature of 115°C, change the heating distillation to heating reflux , reflux reaction for 40min; stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com