7 DEG P low-alcohol beer and preparation method thereof

A low-alcohol beer and beer technology, applied in the field of low-alcohol beer and its preparation, can solve the problems of thin wine body, weak flavor, and light taste, and achieve the effects of fine taste, good color, and good foam retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

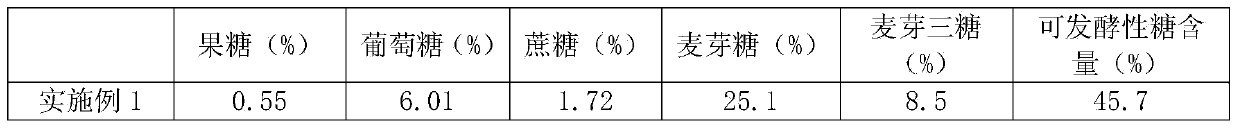

Embodiment 1

[0028] Embodiment 1: the preparation method of 1500L7 ° P low-alcohol beer

[0029] 1) Gelatinization: take 35kg of rice and grind it, add water equivalent to 3.0 times the weight of the rice into the gelatinization pot, raise the temperature to 50°C, put in the crushed rice, add amylase at 0.02% of the weight of the rice, and heat up to 95°C, Keep warm for 20 minutes;

[0030] 2) Saccharification: 60kg of barley malt, 16kg of wheat malt and 8kg of caramel malt are crushed separately, and water equivalent to 3.0 times the total weight of barley malt, wheat malt and caramel malt is added to the mash pot, the temperature is raised to 40°C, and the crushed After the barley malt, wheat malt and caramel malt, add 0.01% and 0.03% of glucoamylase and protease corresponding to the total weight of barley malt, wheat malt and caramel malt respectively, heat up to 50°C, and keep warm for 15 minutes;

[0031] 3) Combine mash and filter: put the gelatinized mash into the saccharification ...

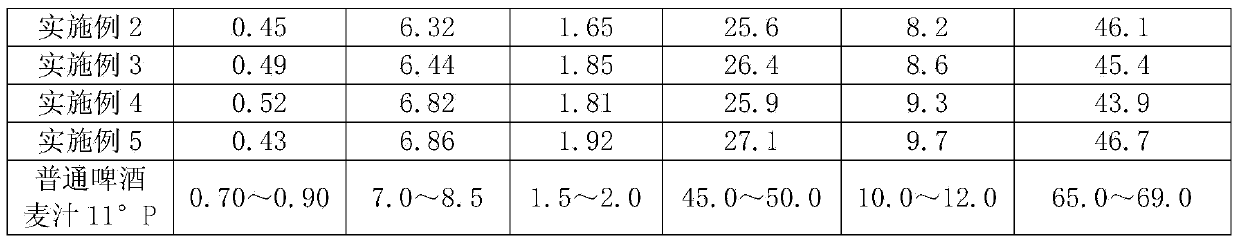

Embodiment 2

[0039] Embodiment 2: the preparation method of 1500L7 ° P low-alcohol beer

[0040] 1) Gelatinization: Take 30kg of rice and pulverize it, add water equivalent to 3.0 times the weight of the rice into the gelatinization pot, raise the temperature to 50°C, put in the crushed rice, add amylase at 0.02% of the weight of the rice, and heat up to 95°C, Keep warm for 40 minutes;

[0041] 2) Saccharification: 58kg of barley malt, 16kg of wheat malt and 13kg of caramel malt are crushed separately, and water equivalent to 3.0 times the total weight of barley malt, wheat malt and caramel malt is added to the mash pot, the temperature is raised to 40°C, and the crushed Add 0.02% and 0.02% of glucoamylase and protease corresponding to the total weight of barley malt, wheat malt and caramel malt respectively, raise the temperature to 53°C, and keep warm for 20 minutes;

[0042] 3) Combine mash and filter: put the gelatinized mash into the mash pot, complete the quick mash within 4 minutes, ...

Embodiment 3

[0049] Embodiment 3: the preparation method of 1500L7 ° P low-alcohol beer

[0050] 1) Gelatinization: take 40kg of rice and pulverize it, add water 4.0 times the weight of the rice into the gelatinization pot, raise the temperature to 55°C, put in the crushed rice, add amylase equivalent to 0.025% of the weight of the rice, and raise the temperature to 95°C , keep warm for 25min;

[0051] 2) Saccharification: 65kg of barley malt, 15kg of wheat malt and 10kg of caramel malt are crushed separately, and water equivalent to 3.0 times the total weight of barley malt, wheat malt and caramel malt is added to the mash pot, the temperature is raised to 50°C, and the crushed After the barley malt, wheat malt and caramel malt, add 0.03% and 0.025% of the total weight of barley malt, wheat malt and caramel malt respectively with glucoamylase and protease, heat up to 55°C, and keep warm for 15 minutes;

[0052] 3) Combine mash and filter: put the gelatinized mash into the mash pot, compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com